- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing line

Results for

Processing line - Import export

FEMIA INDUSTRIE

France

In a fruit or vegetable processing line, storage is often required to feed the line, process the various categories of products and smooth out the flows between the different machines as well as in case of stoppage of the production line.Feed hoppers that depend on the Product Product transport mode or the container The production capacity of the line Buffer hoppers with adjustable feed system.

Request for a quote

FEMIA INDUSTRIE

France

Today, waste management has become a genuine challenge in sustainable development and yield on fruit and vegetable processing lines. Femia provides solutions aimed at extracting only the waste, without affecting the processing of good products. According to a model based on green and circular economy, they are then brought together, recovered and recycled.We design, along with you, a logic for customised waste recovery, according to your material recycling objectives (animal feed, farm use with or without composting), energy (methanisation) or incineration with energy recovery. We integrate the recovery approach right from the design phase for your production lines in order to allow your conveyors progressive and facilitated recovery of wastes all throughout theproduction lines.

Request for a quote

FEMIA INDUSTRIE

France

Conveying is an important element in the performance of your production lines with the dual challenge of limiting product degradation and losses as well as the proper feed on to the downstream machine, an essential point for optimum performance.Belt conveyor, vibrating conveyor, flighted belt elevators, scraper or bucket elevators, hydraulic transporters, we can adapt many conveying solutions to your lines. Our conveying systems must be selected according to the architecture of the preparation line and products processed in order to represent the solution that will provide you with the best performance and meet the particular challenges of your production.In addition to the diversity of the machines that we can apply to your line, our know how resides in our ability to adapt to your needs. We propose a solution that aims to optimise the layout for a minimum amount of space occupied while still including the maintenance constraints.

Request for a quote

TRANSMEC BELGIUM

Belgium

Inventory management: to improve service quality, increase capital savings and save time • Production support with Transmec Group personnel providing handling and material preparation services on the customer’s premises • In-house logistics to redesign product line feeding processes and optimise production efficiency • Procurement and supplies through sourcing and purchase order management • Kitting, packaging and assembly • Component logistics: handling delivery of spare parts and components for your customers through a network of strategically-located warehouses • Reverse logistics for return and warranty services at reduced costs and with improved reliability • E-commerce logistics

Request for a quote

MESUTRONIC GMBH

Germany

FOR INSTALLATION IN PNEUMATIC FIBRE PROCESSING LINES Reliable metal and spark removal. Minimal ejection loss through ultra-fast switching time. Extremely robust – 300,000 switches without visible wear. Suitable for pressure and suction transport.

Request for a quote

WEBER ULTRASONICS AG

Germany

Utilize Weber Ultrasonics technology for your system just like your application demands it. The innovative and highly modular Saphir machine concept is a breeze to integrate in existing process lines and can be customized to individual requirements. The machine components generator, feed unit, swing unit and Touch-PC with the powerful control software SAPHIR CONTROL 4.0 and extensive accessories are pre-configured and ready for use.

Request for a quote

GSW SCHWABE AG

Germany

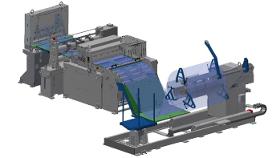

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

MICRO-EPSILON

Germany

For the steel and aluminum industry, Micro-Epsilon offers innovative measuring and inspection systems for thickness, profile and surface measurements. Performance and quality, as well as reliability of products and services have made Micro-Epsilon one of the leading suppliers of inspection systems for optical thickness measurement used in the metals industry. Our non-contact thickness measuring systems are used wherever high-precision thickness monitoring is required for control and quality assurance. Both in hot rolling mills, in continuous casting plants and in cold rolling mills and service centers, the Micro-Epsilon measuring systems operate reliably and with maximum precision. Numerous, successful installations in 13 countries around the world in milling lines and processing lines speak for themselves.

Request for a quote

WILH. KÄMPER GMBH U. CO KG

Germany

Processes such as radial riveting or pressing are used to permanently conjoin a metal plate for example with a wire bracket. Test apparatus for monitoring compliance with the required tear values secure the process in line with these safety-relevant components. These assembly parts are used, for example, as reinforcements for backrest frames.

Request for a quote

ROCHOLL GMBH

Germany

We produce blanks from plastic in line with your specifications. Upon your request, we also process pellets specified and also provided by you in our injection molding department. We keep a wide range of common plastic grades in stock, which we process into test specimens of various sizes according to your specifications. On request we also procure special materials and process these in line with your specific requirements. We process every available type of pellets to form DIN A5 format sheets or smaller sheets lap shear test specimens 100 x 25 x 3 mm dumbbell test specimens We deliver various surface finishes structured high-gloss automotive graining used by a wide range of car manufacturers We deliver every SMC quality depending on the availability of prepregs with class-A finish also in automotive quality Types of plastics ABS, PC, PE, PMMA, POM, PP, PS, PVC, PET, PTFE, PA6, PA6.6, PU, Polymer-based glass fiber-reinforced plastics

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Honing tools from Tyrolit deliver the smoothest surface effects with precision down to the smallest µ-range, essential for industries like cutlery, ski, automotive, watchmaking, and medical technology. These sectors benefit from our extensive range of honing and finishing tools, known for high precision. Tyrolit's dynamic innovation in quality and processes ensures our partners are well-equipped for industry challenges. Best Honing Tools for Various Industries: Our broad assortment offers optimal solutions for any application. In the automotive industry, our products use special polyester film. For superfinishing, the Facetec MF line offers high process stability and cost-effectiveness. The thermal glass industry benefits from our elastic bonded tools for easy metal layer removal. The ski industry uses resinoid-bonded elastic tools to sharpen edges. For precision machining of hip and knee joints, the medical industry relies on our diamond and CBN tools.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

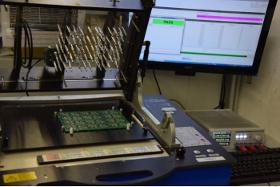

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Test contacts on the circuit board, produced for just this purpose, are contacted by fine, spring-loaded test pins. Depending on the series size, the in-circuit test can take place manually or in an automated fashion. In combination with other test processes, including tests without test contacts, over 90 percent of all errors can be detected.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WEBER FOOD TECHNOLOGY GMBH

Germany

Perfect fit: Fat remover ASF 560 E for pork belly and loin of pork. Maximum yield with little post-processing. Optimised blade holder profile for exact adaptation to the cross section of the product. Electronically controlled movement along longitudinal profile for exact adjustment to the fat contours. The result: Less fat on the pork belly/loin, less lean meat in the belly/back fat. Advantages Minimal post-processing after the processing workflow Line concept: Perfect integration of the machine in stripping workflows Options: Operating personnel can also remain outside the machine stand Curved blade holder profile for ideal product adaptation Special sub-frames (height adjustment)

Request for a quote

MTA ROBOTICS AG

Switzerland

The laser MRC500 is the larger robotic cell that supports point to point laser soldering from above. The standardized platform is based on a flexible and modular concept that can be adapted to a range of processes from fully-automated in-line to stand-alone semi-automated processes. The frame of the laser MRC500 is designed to ensure the safety of the operator during the laser soldering process. Furthermore, it also provides maximum accessibility to the working area. The laser robotic cell is only equipped with mta MLH45 laser head. The main features of our laser MRC500 include: Welded frame construction 3-axis Cartesian robot 500x500mm working area Industrial PC controller with Embedded Windows® operating system Intuitive menu-driven mta MotionEditor software

Request for a quote

MINEBEA INTEC GMBH

Germany

Vistus metal detectors are capable of detecting both ferrous and non-ferrous metals and are specifically designed for the food industry. They can be supplied mounted on a belt or chain conveyor, allowing an easy and fast integration into your processing or packaging line. Sturdy and torsion free construction made of 1.4301/AISI304 stainless steel High quality drives: maintenance free three-phase motor with worm gear or three phase drum motor Maximum detection performance through optimum vibration control and metal free zone Available standard coil sizes: 75 x 30 mm up to 275 x 60 mm Extremely compact: control unit fully integrated in detection coil Standard IP65 protection class, IP69K optionally available for enabling high pressure water cleaning

Request for a quote

ROSSI INGEGNERIA ALIMENTARE SRL

Italy

We offer process solutions for all types of fruit and for all stages of production: from the delivery of fresh fruit, through extraction or pressing to the final packaging of the juice aseptically or by hot filling. Alternatively, we build plant for the preparation of quality juice, starting from pureés and concentrates in aseptic drums, while respecting the organoleptic properties of the fruit. In both cases, our technologies ensure that a homogeneous and natural liquid is obtained thanks to a perfect combination of the blended products. All Ing.A.Rossi production plant is highly automated, and can be operated from a control room, in order to minimise operator error and guarantee repeatability and precision in the process. Production lines can also be integrated with waste water purification plants, and can cater for both small and large-scale production: we don’t have any volume limits. Extraction, pressing or preparation of highest-quality

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small sized computer controlled deflashing machine can be integrated into the production line easily. This saves temporary storage or extra transports and finally corresponding time loss and costs. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. Alternatively the E30 is available with quick-exchange basket system. This basket is compatible to our high-pressure washing machine W30 and furthermore optimally suited for a linear in-line-processing →production →deflashing →washing →termpering, as this charge-baskets may be used compatible for each machine. For industry 4.0 demands, the E30 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small-sized machine can be integrated into the production line easily. This safes temporary storage or extra transports and finally corresponding time loss and costs. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. By special request, siliconisation or coating with other glide agents is also possible. The W30 uses exchangeable bastekts for the (un)loading. These baskets are also compatible to our cryogenic deflashing machine E30W, and furthermore, optimally suited for a linear in-line processing → production → deflashing → washing → postcure tempering, The W30 is best pepared for industrie 4.0 demands. (on option with OPC UA server) With this small-sized machine, your treatment capacity is at best cost-performance ratio!

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Fusion™ 6HF – s200 is a heat treatable product for applications with extremely demanding formability requirements. This product is recommended for inner applications such as decklid and door inners and other closure inner panels. This product has an excellent balance of properties for forming and strength. In addition, it offers a unique advantage in the hemming process enabling sharp feature lines and rope hem designs that permit the reduction in perceived gap between adjacent panels. All values are typical.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Fusion™ 6HF – e200 is a heat treatable product for applications with extremely demanding formability requirements. This product is recommended for outer applications such as body sides and decklid outers. This product has an excellent balance of properties for forming and strength. In addition, it offers a unique advantage in the hemming process enabling sharp feature lines and rope hem designs that permit the reduction in perceived gap between adjacent panels. All values are typical.

Request for a quote

EC PLAZA

South Korea

DH Lighting has been leading Automotive Lighting Industry of the world under the spirit of Trust, Technology and Future since 1994. Automotive Halogen Bulbs are the main stay of DH Lighting which is well-known as “EXCELITE” brand through the export more than 50 countries as well as OEM supply to Korean and overseas car makers. We have the largest production capacity of the bulbs in Asia which covers the full ranges with the highest OEM quality by its own automated production lines. Each manufacturing process in the factories is under the strict control with ISO/TS 16949, IATF16949, ISO 9001 and OHSAS18001. All standard bulbs have been acquired the world top class quality approvals such as E1 and SAE-DOT.

Request for a quote

GSW SCHWABE AG

Germany

Slit metal often has camber. GSW builds Camber Straighteners, that help remove this defect. Coil Feed Lines that process small crosssections often only need minor straightening efforts. Here, we can help with pullthrough Straighteners also known as Flatteners. We usually mount them at the entrance of our Servo Roll Feeds or Air Feeds. Wire materials also often have a coil set – sometimes in two levels even. Single and dual Wire Straighteners help making such bent wires straight again.

Request for a quote

MINEBEA INTEC GMBH

Germany

VisioPointer® reliably automates inspection processes in food packaging lines using leading vision technology and multiple inspection types. Its intuitive interface and intelligent data usage allow operators to ensure product quality, reduce waste and downtime, and optimize the production. As a plug and play vision solution, VisioPointer® makes thorough quality control achievable for any food manufacturer with easy implementation, operation and maintenance.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

FireFox® 2 C – With setting process monitoring This tool is based on the proven TAURUS® C model. Here the setting process is analysed via integrated electronics using stroke and force sensors. The user can defi ne an OK window by means of a special software. A coloured LED on the tool shows the results of the setting process monitoring which can also be recorded and processed via data line. Apllications In the serial production of safety component parts as well as in automated setting processes the FireFox® C allows checking and documentation of the setting process. Advantages • High process safety • Documentation of each individual setting process • Less scrap since errors can be immediately identifi ed

Request for a quoteResults for

Processing line - Import exportNumber of results

132 ProductsCountries

Company type

Category

- Seals and packing material (8)

- Mechanical engineering - custom work (5)

- Conveyor systems (4)

- Cosmetics industry - machinery and equipment (4)

- Food canning and preserving - machinery and equipment (4)

- Motorcycle clothing (4)

- Sorting and sizing equipment for fruits and vegetables (4)

- Electrical & Electronic Components (3)

- Hygrometers (3)

- Laboratory equipment and instruments (3)

- Steam polishers (3)

- Toilet paper (3)

- Cars - electrical and electronic parts and components (2)

- Fabrics for technical use (2)

- Food Processing (2)

- Food industry - machinery and equipment (2)

- Measurement - Equipment & Instruments (2)

- Metal straightening machines (2)

- Rubber - industrial machinery and equipment (2)

- Slaughterhouses - machinery and equipment (2)