- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool change

Results for

Tool change - Import export

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The automatic feeding of tools from the tool magazine to the machining spindle is implemented in modern machining centers with the aid of a tool changer. At the same time, this device is used to return tools to the tool magazine. Reducing non-productive times is an important criterion for increasing the efficiency of machining centers. The chip-to-chip time is directly positively influenced by a fast tool change, i.e. a short tool change time.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

SUPER HAND replaces work. SUPER HAND is ultrasmall, ultralightweight; yet performs with the power and efficiency of a much larger tool to meet user requirements of filling, chamfering and other jobs. It comes with the quickchange tool points for different jobs. You can work on steel, glass, brass, aluminium, wood and other materials silently. It also handles scores of big jobs with speed and ease.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

SUPER HAND is ultrasmall, ultralightweight; yet performs with the power and efficiency of a much larger tool to meet user requirements of filling, chamfering and other jobs. It comes with the quickchange tool points for different jobs. You can work on steel, glass, brass, aluminium, wood and other materials silently. It also handles scores of big jobs with speed and ease.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

User friendly, stable and very precise. By combining taper concentricity with no backlash with an extremely large planar surface, combined with high torque, BENZ Solidfix® offers a maximum in stability and rigidity, which is even capable of withstanding the demands of milling. The high torque transmission and the highest possible rpms also stress the effectiveness. This is supported by a special clamping mechanism which works centrally, without lateral forces, which in combination with the compact, highly precise components used achieves optimal values for concentricity, rigidity and accuracy in repeatability. Because of its compact design the system is ideal for tools with internal cooling.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Increase of efficiency and machining quality The modular quick change system BENZ CAPTO™ guarantees an extremely compact desgin by being integrated into the spindle. Special clamping kinetics for clamping forces are noticeably below the required range of ISO/DIS 26623-2. BENZ CAPTO™ can be used for milling, drilling and turning, with up to 100 bar coolant pressure. The system is especially suited for heavy duty milling and machining.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Quick change in confined spaces BENZ Nanofix® is a new quick-change interface that is convincing thanks to its extremely compact design. The outer diameter of 22 mm is designed for minimal spindle distances and is therefore particularly suitable for use in confined spaces.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS.PSC offers maximum stability and rigidity coupled with maximum flexibility. Significantly reduce your setup and changeover times while maintaining high mold flexibility. he EWS.PSC program includes a wide range of standard tools with PSC shank for milling spindles as well as tool systems with PSC spindle for lathes. Furthermore, tool holders with plate seat are available. The interface allows you to reduce the time spent measuring, setting up and changing tools. In addition, improved machine utilization can be achieved.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Mount tools safely and in the correct position while remaining flexible, all this is possible with the UMB100 mounting unit. The tool clamping units can be changed quickly, making the system an ideal mounting aid for multi-tasking machines. It only takes a few seconds to replace an adapter. The unit with snap-in swivel can be pivoted 4 x 90° at the touch of a button so that even angled holders can always be mounted in the ideal position. Universal mounting block UMB100 Tool holder for VDI holding fixtures Tool holder for Varia VX Tool holder for steep-angle taper holding fixtures

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The rapid change system EWS-Varia allows to set-up a modern CNC lathe or a turning milling center – and this flexibly. A tool change will just take 20 seconds, which is an unbeatable argument especially in small batch productions whenever it is about reducing the set-up time and thus increasing the productivity. The advantages, however, are also evident in large batch productions. Preset twin tools lie at the machine, thus significantly reducing the down-times. A further advantage is provided by the variety of adaptations; so the optimal tool clamping can be selected for each operation. The inserts available include: Collet chuck holders Weldon/Whistle Notch Milling arbors Morse tapers Hydro extension Shrink adaptations The most important advantage is certainly created by the easy handling. The inserts can be changed with just one hand without counter pressure by the spindle.

Request for a quote

COPIER MACHINERY

Netherlands

Beaver CNC series is designed with the latest innovation and capable of finishing the pipe with both radial and axial feeding of the tool. Multiple applications like pipe beveling, facing, squaring, deburring, tapering, and threading can be performed on the inside and outside of a pipe without a need for a change of the tooling for different angles or shapes.

Request for a quote

COPIER MACHINERY

Netherlands

Beaver CNC series is designed with the latest innovation and capable of finishing the pipe with both radial and axial feeding of the tool. Multiple applications like pipe beveling, facing, squaring, deburring, tapering, and threading can be performed on the inside and outside of a pipe without a need for a change of the tooling for different angles or shapes.

Request for a quote

COPIER MACHINERY

Netherlands

Beaver CNC series is designed with the latest innovation and capable of finishing the pipe with both radial and axial feeding of the tool. Multiple applications like pipe beveling, facing, squaring, deburring, tapering, and threading can be performed on the inside and outside of a pipe without a need for a change of the tooling for different angles or shapes.

Request for a quote

COPIER MACHINERY

Netherlands

Beaver CNC series is designed with the latest innovation and capable of finishing the pipe with both radial and axial feeding of the tool. Multiple applications like pipe beveling, facing, squaring, deburring, tapering, and threading can be performed on the inside and outside of a pipe without a need for a change of the tooling for different angles or shapes.

Request for a quote

SYNERLINK

France

EL SLEEVE is a sleeving machine from the bottom-up. The continuous sleeving technology ensures repeatability for positioning of the sleeve graphic in relation to the lid graphic without turning the cups. This ultra-compact machine can sleeve cups at a speed of 43,200 cups per hour. EL SLEEVE is a flexible sleeving machine adaptable to any cup format on any FS or FFS line. Format change is fast and easy. Changing format does not mean necessarily changing tools.

Request for a quote

MAROVT D.O.O.

Slovenia

The advantage of the Marovt company is that forged parts are machined in our own forge. This is why we are able to ensure forged parts with characteristics defined together. The machining of forged parts is mostly automated; therefore, the human factor is decreased and permanently the same technological process can assure all parts to be machined in the same way and being controlled and tested according to the same procedures.The machining of forged parts is carried out on technologically advanced 3 and 4-axe machines. Our machining centres have the possibility of using up to 40 changeable cutting tools. The tool can be up to 300 mm long and up to 10 kg heavy.The machining center spindle can rotate up to 20,000 rpm. Changing the cutting tool at our centers only takes 1.7 s, which greatly shortens the machining time. All our machining centers have a pallet system that eliminates the time of mounting the forging parts into the clamping device.

Request for a quote

SAMSYS GMBH

Germany

Do you want to use the OnRobot grippers as double grippers? The Dual Quick Changer double gripper system allows the use of different OnRobot gripping tools in one pass. With this innovative solution, you can use two RG2 grippers or one RG6 gripper with a VG10 – it’s up to you. Switch quickly and seamlessly between our tools with the Dual Quick Changer to maximize the utilization of your robots. With the Dual Quick Changer, throughput times can be accelerated and thus the productivity of your plant increased. Not only suitable for OnRobot products. The DUAL Quick Changer can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example are existing tools, which can also be equipped with the OnRobot quick-change system. The Dual Quick Changer is the alternative to the Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

SAMSYS GMBH

Germany

The Quick Changer system enables quick and easy tool change. It has a low weight, a low installation height and is designed for a payload of up to 20 kg. It is patented, reliable and equipped with a user-friendly connection mechanism. Particularly secure locking structure and locking springs. The Quick Changer system is a unique product and ideal for all collaborative robotic applications. The Quick Changer is the easiest and fastest tool changer. Simply everything you need in one package. Not only suitable for OnRobot products. It can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example is the use of existing tools. These can also be equipped with OnRobot’s quick change system. The Quick Changer is alternatively also available as Dual Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Powerful, long-lived, precise: GMN motor spindles for manual or automatic tool change stand for quality and efficiency, and are well-suited to your grinding, milling, drilling or special applications.

Request for a quote

SIKO GMBH

Germany

Profile AP24: For tool change and target value specification Remote display without actual value measurement Acknowledgement button integrated bus interface (RS485) Two-line LCD-Display User guidance via bicolor LED M8 plug connection

Request for a quote

HO-MA GMBH

Germany

Increased output for further processing Tool-free format change Quick adjustment to product formats Selectable direction of rotation

Request for a quote

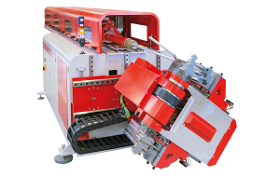

TRANSFLUID® MASCHINENBAU GMBH

Germany

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most extreme geometries on tubes. With our clockwise/counterclockwise bending machines – also available with push bending function – the most complex bends become reality with great accuracy.

Request for a quote

PRESSTA EISELE GMBH

Germany

4 axis CNC floor type vertical spindle machining centre. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of profiles. Suitable for processing on ANY surfaces, generated by the rotation of the spindle axis (side by side at Y axes) on the positions within 180° (± 90°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. The working table can be divided in two areas so to get two separate working stations. Using a disk cutter, it is possible to work on both sides at the end of the profile (end milling cycle). Milling operations can be performed with linear and circular interpolation of the axes X-Y-Z. The hinging length stop are pneumatically managed. The electric spindle is suitable for quick tool holder change. The tool magazine is mounted on the mobil upright. The tool change can be carried out into any position...

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-performance spindles with an integrated motor are designed for those applications and relevant installation situations in close collaboration with our customers. They are available as needed with a synchronous or asynchronous motor, for manual - HGS series - or automatic tool change - HGC, HGT series - and with oil-air or grease lubrication. Additional options are, for example, an AE sensor, vibration sensor or an automatic balancing system.

Request for a quote

SIKO GMBH

Germany

with bus interface, for format part or tool change Profile AP10T: setpoint display with bus interface without measurement of actual value large control key to confirm target value optimally readable backlit display Two-line LCD-Display integrated RS485 interface, CAN bus as an option user guidance via bicolor status LEDs IP53 type of protection, IP65 as an option

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydropneumatic intensifier Foot valve operated Max. power at 10 bar = 50 KN Stroke = 37 mm Max. daylight = 200 mm Working range: ram to back wall = 110 mm Swiveling table to use tools to manufacture holes for sash bars

Request for a quote

PRESSTA EISELE GMBH

Germany

Quick change tool system Hydropneumatic intensifier Foot valve operated Max. power at 10 bar = 90 KN Stroke = 40 mm 25 Double strokes / min. Max. daylight = 250 mm Working range: ram to back wall = 130 mm Working range with turn table: ram to back wall = 90 mm Working height 950 mm

Request for a quote

PRESSTA EISELE GMBH

Germany

Base with hardened guides Hydraulic device; Motor 4,0 kW, 400 V, 50 Hz Operation panel to switch on/off single or multy head mode Foot pedal controlled C-formed stand, working range – ram to back wall 120 mm Daylight 280 mm, quick tool change Distance punch head to punch head min. 245 mm Punching power 60 / 120 kN, stroke 50 mm – stroke adjustable optionally Carriage with linear guides for manual adjustment in X-direction, with pneumatic clamps and positioning scale

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly wellsuited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step userfriendly and fully programmable individually. We offer the option to equip our systems with electric or hydraulicnumerical drives. These forming processes can be completed stepwise in transfer system to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

X2000NC for producing door strikers Modular tool set on an X2000NC line for the production of door strikers from 8 mm wire. Striker sprinter tool, 3 stations, 2 m back wall, feeding of coil material via NC roller infeed, cycle output: approx. 60 pcs/min, ready-to-use, weight approx. 10 t Door striker production With these specifications, our X2000NC is the world’s fastest system for the production of door strikers for the automotive industry. With tool changes, different striker shapes can be achieved, as well as processing details such as upsetting or tapering at wire ends. Our one-of-a-kind production model enables cycle times of more than 60 pcs/minute. For this reason, we’d prefer not to share the technical details of our strategy online. If you’re interested, please arrange a meeting with a member of our field sales team. Incidentally, we also build assembly systems for coupling door strikers to striker plates.

Request for a quoteResults for

Tool change - Import exportNumber of results

177 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (10)

- Machine tools, metal machining - parts and accessories (9)

- 3D scanner (8)

- Bending machine tools (8)

- Industrial cutting machine tools (6)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (6)

- Forming - steels and metals (4)

- Milling - machine tools (4)

- Thread-cutting - machine tools (4)

- Metallurgy - machinery and installations (3)

- Pipes and tubes - ferrous metal (3)

- Robotics (3)

- Adjustment - machine tools (2)

- Brakes, servo-brakes and accessories (2)

- Food Industry - Machines & Equipment (2)

- Hydraulic equipment (2)

- Labelling machines (2)

- Meat processing machines (2)

- Mechanical engineering - custom work (2)

- Needles, industrial (2)