- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool change

Results for

Tool change - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

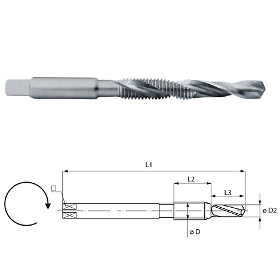

Thread standard: Metric, ISO DIN 13 Type: Combined machine tap (core hole drilling and thread tapping) Application: Combined (core hole drilling and thread tapping) Material of product: HSSE Surface treatment: no For materials: Materials of medium mechanical strength (alloyed and non-alloyed steels up to 600 N/mm², Malleable cast iron, Graphite cast iron, Copper, Brass, Aluminium, Aluminium-magnesium alloys, Zink alloys, Red bronze, Electron metall, Pressure-cast zink) Tensile strength up to: 600 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Combined machine taps enables the user to produce the tapping drill hole and the through thread in one operation without any tool changing. The tool incorporates a twist drill before the thread-tapping part. It is possible with this tool to produce through threads up to a maximum threaded depth of 2 x D. It is sensible to use this tool on machines possesing an RPM switchover facility for drilling and tapping.

Request for a quote

CABA INDUSTRIE

Italy

Single reversible In-row cultivator, mountable both in front and behind the tractor, to perform multiple workings in vineyards and orchards thanks to the possibility of changing the mounted tools

Request for a quote

CASEARTECNICA BARTOLI SRL

Italy

The EVO propeller stirrer is the natural evolution of the classic standard stirrer by Caseartecnica Bartoli. Equipped with brushless motor with permanent magnets without reducer and no oil inside, it prevents product contamination and reduces the environmental impact. In addition to being built entirely in stainless steel and materials compatible with food contact, it guarantees energy savings. Other important features are the degree of protection IP65, reduced dimensions and reduced maintenance. The agitator is designed for quick tool change according to the various processing stages: heating and cooking, pinning with the cutting of the curd, final cleaning of the double bottoms.

Request for a quote

SAMEC S.R.L.

Italy

The End-of-Arm Tooling system for Sheet Metal handling named Octopus Grip consists in an octogonal-shaped central arm, attached to the wrist of the Robot Grips, specifically studied to be highly resistant to deflections/vibrations, with holes for the internal passage of air, and two or four patented quick ball coupling systems. The quick ball coupling systems allow the reconfiguration of the Robot Grips by simply changing their end effectors, in this case the tentacles of the Octopus Grip, that can be easily unhooked and placed close to the Robot Grips by a single operator on a vertical warehouse, allowing for savings in time required for changing the tools, and in storage space. The Octopus Grip system is highly flexible, from which it derives its name.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tool change - Import exportNumber of results

4 ProductsCompany type