- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool change

Results for

Tool change - Import export

APD MAQMASTER

Spain

1. More stable and welcome mature CNC corner cleaning machine for pvc window processing. 2. Totally 5 cutters (two pieces of vertical milling cutters, two pieces of pulling blades, one piece of saw blade) will automatically clean the surface, vertical groove and inside of the rubber gasket. No tool change required. 3. Complete machinery controlled by advanced IPC works automatically precisely. 4. The cutters are controlled by spindle motor, much more stable, they are on CNC axis, very easy to adjust. 5. Two axes moved by ball screw shaft. 6. Within 25 seconds, complete one corner complete cleaning. 7. It can be connected with horizontal welding machine to become welding and corner cleaning production line for great imagination and high efficiency. 8. Friendly operation. Fast learning. 9. Optional: a piece of horizontal milling cutter, used for sliding windows.

Request for a quote

APD MAQMASTER

Spain

1. Advanced CNC machining center with servo turning table and 4 servo clamps. 2. Suitable for processing aluminum profiles (up to 3mm thick) and steel profiles (up to 2mm thick) with super fast speed (5m/min) and efficiency thanks to laser technology. High pressure air compressor (1.6Mpa) and cooling station are included. 3. The machine completes milling, drilling, chamfering, slotting and other multifunctional precisely in one time. 4. The work table will be positioned from +90° to -90° variable angle. 5. Automatic lifting safety cover ensures operator safety. 6. Automatic tool change: standard equipped with 6-position hidden tool magazine, standard equipped with 3 tool holders. 7. Operation in Windows environment industrial PC with monitor. Friendly machine interface with user-friendly operation. 8. In line with ERP software, it can perform code scanning and automatic processing.

Request for a quote

APD MAQMASTER

Spain

GARNET ECO offers its user a flexible work area thanks to the manually moved jaws that can be adjusted in height according to the profile. Users also appreciated the high processing capacity (200 mm x 180 mm) when performing these operations. Thanks to the built-in 5-tool manual change station, you save time when performing different operations. Thanks to the automatic tool tip cooling system in the spindle motor, it allows you to create a clean and precise machining surface and extends the life of the tool tip. The GARNET ECO machining center is an essential tool in any machining workshop that seeks maximum efficiency and productivity in its daily work. Thanks to its compact and versatile design, this equipment is capable of performing multiple machining operations with high precision and quality.

Request for a quote

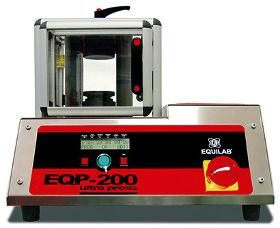

EQUILAB

Spain

The EQP-200 Pellet Press has been especially designed to obtain high quality pellets/tablets for XRF. This press can exert a pressure of up to 40 tons. Of durable and robust design, it is very easy to manage, efficient, and offers 5 working programs with single and double pressing cycles. An exceptional instrument. Keeping all the features of its predecessor (EQP-100), the EQP-200 also offers the possibility of making pellets of different diameters, just by changing the pressing tool. This device facilitates also the cleaning and maintenance tasks. Its versatility enables the unit to work also with different shapes of press tools, such as square, rectangular, etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tool change - Import exportNumber of results

4 ProductsCompany type