- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electronics assembly

Results for

Electronics assembly - Import export

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Optimel is your reliable partner for solutions for encapsulating electrical and electronic assemblies. The innovative Low Pressure Moulding (LPM) technology offers optimal protection against external influences such as moisture, dust and vibrations, thus ensuring the longevity and reliability of your products. The Low Pressure Moulding process or hotmelt moulding process originated in the sealing of cable harnesses in the automotive industry - today it is used in many areas for the protection of electrical and electronic components. At 5-40 bar (in individual cases up to max. 60 bar), processing takes place at a much lower pressure than in the classic hotmelt injection moulding process. This makes it easy to directly encapsulate even sensitive components such as circuit boards, sensors, etc. The cycle times are limited to pure encapsulation

Request for a quote

INTEGRAL COMPLEX SYSTEMS

Ukraine

We carry out a full cycle of development of electronic devices: supply of electronic components, stencils and printed circuit boards, design of electronics, redesign of finished devices. Applying the principles of lean production, we achieve a price reduction while maintaining a high quality of services. Due to quality control at all stages of production, we have the reject rate less than 0.5% (at observance of all requirements to the order). Operative daily planning allows us to achieve maximum efficiency in the use of working time. Thanks to that, in the presence of all the equipment in the warehouse, we can take the order to work during the day from the moment of order. We have our own high-tech equipment, and offering good quality with competitive assembly cost.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear NT is a linear motor drive high thrust pick & place unit with compact integral X and Zaxes, using IKO CLube Linear Way ML in the table guiding parts. Thanks to the adoption of a system which drives the moving table with a link mechanism, it realizes both higher thrust of the linear motor and weight reduction of the moving parts and reduces tact time. By entering a positioning program, you may set flexible operation patterns and change strokes easily according to the workpiece. IKO Nano Linear NT is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment and electronic parts assembling machines which require a clean environment.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Component placement requires individual approaches. Our range of solutions covers small series produced by hand, medium-size series using semi-automated wave soldering machines and fully automated production lines for large-scale manufacture. We adjust the level of assembly automation to your project – so that you achieve the best result both economically and technically.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Whether it's manual soldering with robotic support, wave and selective soldering or laser soldering – in all assembly tasks, we are able to use any technique required without a problem. Depending on the component, different soldering technologies offer different advantaged. We will adjust the process individually to your project.

Request for a quote

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

PLUS SAFETY

Turkey

Features & Applications -Building construction -Fiber exposure and fiberglass products manufacturing -Pharmaceutical manufacturing -Painting and spraying workshop -Electronic assembly and insulation laying -Mining, wood, and metal processing -Motor vehicle and ship building -Agriculture and veterinary services -Asbestos removal, stripping, and clear-up or handling

Request for a quote

TEPROSA GMBH

Germany

Testing services from a specialist: we are specialized as a testing laboratory for the simulation of specific environmental conditions and the monitoring of the influences of these conditions on electronic assemblies. We offer the following services in our test lab and at your site as contract testing.

Request for a quote

TEPROSA GMBH

Germany

Mechatronic integrated devices or molded interconnect devices (injection-molded circuit carriers) are spatial electronic assemblies – so-called 3D-MID. A special process is used to apply metallic conductor tracks to a specific substrate material (often plastic), thus creating three-dimensional assemblies that also serve as circuit carriers. These spatial electronic assemblies are manufactured using 3D-MID technology and, compared to conventional assemblies, enable the integration of electronic, mechanical, fluidic, optical and thermal functions. The resulting additional benefits represent advantages that cannot be realized with two-dimensional circuit carriers (printed circuit boards).

Request for a quote

DYMAX EUROPE GMBH

Germany

Dymax GA201 forminplace (FIP)/cureinplace (CIP) gasketing resin is formulated for sealing plastic, glass and metal enclosures, and plated surfaces for automotive door handle, appliance housing, and critical electronic assembly and device applications which require a soft, tackfree, flexible gasket. Features: - Cures with UV/Visible light - Moisture resistant - Chemical resistant - Tackfree cure - Soft, durable after complete cure - Conforms to intricate channels and recesses - Compliant with RoHS directives 2015/863/EU

Request for a quote

DYMAX EUROPE GMBH

Germany

Dymax GA140 forminplace (FIP) and cureinplace (CIP) gasketing resin is formulated for fuel cell, automotive door handle, appliance housing, and critical electronic assembly and device applications which require a soft, tackfree, lowoutgassing, flexible gasket with compression set. Features: - Cures with UV/Visible light - Low outgassing - Cures soft and tack free - Excellent tear resistance - Clear in color - Cures in seconds - Silicone free - Conforms to intricate channels or recesses - Compliant with with RoHS directives 2015/863/EU

Request for a quote

TEPROSA GMBH

Germany

In an environmental simulation, assemblies are subjected to defined environmental conditions to validate their behavior under those conditions. The variables of an environmental simulation test include climatic aspects such as temperature (cold, heat), the air conditions (humidity, wetness), mechanical influences such as dust, vibration, vibration or impacts, and corrosive environmental effects such as salty lift (salt fog). As an environmental simulation laboratory, we simulate these environmental conditions in our climatic chambers and climatic chambers, creating real conditions to investigate the long-term behavior of the test specimens in reality. Environmental simulation and thermal shock testing laboratory for electronic assemblies and printed circuit boards We specialize in performing environmental simulation and temperature shock testing of electronic and mechanical assemblies. With over ten years of experience with the requirements of the automotive industry and medical

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

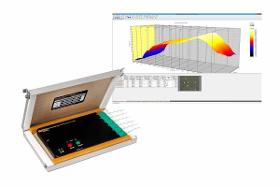

The Datapaq® Reflow Tracker® temperature profiling system travels through the process, enabling you to monitor wave and reflow soldering, as well as vapor phase, selective soldering and rework stations. Comprised of specifically designed thermocouples, data loggers, protective thermal barriers and Insight software, this system will help you optimize product quality, expedite process setup, increase yields and minimize the need for rework. For more details and specifications, download the Reflow Tracker System brochure. Insight Software for Reflow Tracker available in Basic, Standard and Professional versions Insight software is an easy-to-use analysis package designed by Datapaq to meet the needs of the electronics assembly industry. With a typical reflow soldering profile lasting only six minutes, users don't want to spend additional time analyzing the profile. Insight Software ensures that the user is presented with a detailed analysis immediately and it comes

Request for a quote

TEPROSA GMBH

Germany

We are specialized in performing thermal shock testing of electronic and mechanical assemblies and have a lot of experience with the requirements of the automotive industry and medical technology. On behalf of our customers, we perform environmental and climatic tests according to customer specifications and applicable standards, thus uncovering optimization potential. We will be happy to advise you with regard to your testing tasks and, together with you, transfer the entire testing process into a specification sheet. OUR OPPORTUNITIES 2-chamber system air-air Test chamber volume up to 130 liters Temperature range hot chamber 50°C to 200°C Temperature range cold chamber -80°C to -100°C Change between chambers <15 seconds Maximum test material weight 25 kg State monitoring of the test specimens during the test

Request for a quote

TEPROSA GMBH

Germany

With the help of the 3D-MID process, plastic parts can be metallized not only over the entire surface, but also selectively. To do this, the plastic part is activated with a special laser at the points that are to be coated (this is referred to as laser activation or laser direct structuring). The additives contained in the plastic directly under the plastic surface are “exposed” by the laser treatment. In a chemical bath, copper particles can then be deposited specifically only on the activated surfaces. Other metals, e.g. nickel, tin or gold, can then be deposited onto the starting layer of copper. In this way, a selectively coated plastic part is obtained. MID technology thereby makes it possible to selectively coat two-dimensional and also three-dimensional plastic parts and use them, for example, as circuit carriers for electronic or mechatronic assemblies. With the LPKF-LDS process

Request for a quote

TEPROSA GMBH

Germany

We offer laser direct structuring (LPKF-LDS process) for the production of 3D-MID (so-called three-dimensional circuit carriers) as a service in Magdeburg. 3D-MID stands for Mechatronic Integrated Device (or Molded Interconnected Devices). The MID technology makes it possible to use three-dimensional plastic parts as circuit carriers for electronic or mechatronic assemblies. The LPKF-LDS process is one of the technologically leading and at the same time most economically interesting process for the production of 3D-MID. The LPKF LDS process represents the central process step. The process was developed and patented by the company LPKF Laser & Electronics AG in Hanover.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Up to 60 rivets per minute! – Endorsed by major customers! GESIPA® speed rivets are a cost-effective alternative to automation. Speed rivet technology is a joining method that requires access from only one side and which enables fast cycle times thanks to the preloaded rivets and automatic feed. Advantages • Large grip range • Reduced variation • Optimum hole filling capabilities and bearing stress • Ideally suited for transferring shear strengths with moderate clamping force • Ideal for: — LED light strips — Electronic/pcb assembly — Lightweight sheet metal structures — PC housings — Rating plates — Blind holes

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Special machines for the automotive and supplier industry Machine system for low pressure molding - electronics encapsulation The FLEXline series offers maximum flexibility through the modular design of various variants as well as expanded options for implementing special functions. The adaptation or addition of individual mechanical components is just as possible as special programming or integration into a complete production line. In addition, various application systems are available, including hot runner systems with different nozzle geometries and arrangements. The melting units can be optimally tailored to the requirements of the respective project with different melting and conveying systems and, if project requirements differ or change, can be replaced at any time using our "plug-and-play" system. Extensive peripherals and additional options round off the system. The FLEXline can therefore be optimally tailored to the requirements of the respective project.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Special machines for the automotive and supplier industry Machine system for low pressure molding - electronics casting The BASEline series combines a compact design and convenient operation and can be used optimally for the majority of low pressure molding projects. Various mechanical components can be put together depending on requirements. The adapted melting device with double-acting piston pump, 4l tank volume and a melting capacity of approx. 1kg/h enables optimal processing of small to medium shot weights and/or quantities. The available clamping force of 9/12kN is suitable for casting surfaces up to approx. 3,000mm². By using the Siemens S7-1200 control with touch panel, the series offers the same ease of use as the larger series.

Request for a quote

SEIFERT ELECTRONIC GMBH

Germany

Our thermal management and insulation products are far from being just interim solutions. The Thermal Interface Materials (TIM) from Seifert electronic GmbH ensure optimal thermal connection between heat sinks and the components to be cooled. As electronic assemblies become increasingly compact, even a tiny gap between individual components can disrupt the necessary heat dissipation. Air pockets between the heat sink and the component being cooled hinder the optimal thermal connection. Possible consequences include temperature overload, which can lead to overheating in the worst-case scenario. Thermal management and insulation products act as connectors between the heat sink and the electronic component being cooled. They fill every tiny gap between the heat sink and semiconductor with thermally conductive material. This ensures optimal thermal connection and prevents any heat buildup.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera ceramic blades are designed for high performance and precisions cutting processes in various including film and foil, medical, converting or assembling of electronic components. Market leaders around the globe have chosen our solid ceramic slitting blades to improve their cutting application.

Request for a quote

HODA, UAB

Lithuania

HODA, UAB offers plastic manufacturing assembly and packaging services. We have experience in the post-mold handling of components and can offer our Customers a finished assembly or complete packaging – customer ready for distribution or resale. Often times these value added operations can be performed within the molding cycle, yielding lower costs and improving your competitive edge. This turnkey approach saves your company time and money, resulting in a single point-of-purchase providing quick, flexible and cost-effective production of assemblies that are complete and ready for use.

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

Tower is a group of manufacturing facilities, offering one-stop solution for quality mechanical products with total lower cost in China. We can supply a full-range of metal products, such as sheet metal fabrication, cnc machining parts, casting parts, especially assembly parts. Product market range cover auto industry, medical industry,agricultural machinery, sport industry and so on. Because of our complete equipments, we are very suit for making all kinds of Assembly Parts. All of our products are customized by customer's drawing. Please feel free to send us your drawing or sample to customize!!!

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

Tower is a group of manufacturing facilities, offering one-stop solution for quality mechanical products with total lower cost in China. We can supply a full-range of metal products, such as sheet metal fabrication, cnc machining parts, casting parts, especially assembly parts. Product market range cover auto industry, medical industry,agricultural machinery, sport industry and so on. Because of our complete equipments, we are very suit for making all kinds of Assembly Parts. All of our products are customized by customer's drawing. Please feel free to send us your drawing or sample to customize!!!

Request for a quote

BELIT ELEKTRONIK LTD

Turkey

Belit Electronic manufactures the cable assemblies, wire harnesses and battery cables needs of the UPS industry, which it has been closely following for many years.

Request for a quote

MFO S.A.

Poland

Mounting rails used for assembly of modular equipment, wires and cables. Bars ideally meet installation requirements and harmonize with the interior. Steel mounting rails are applicable in a wide range of home and industrial installations. Product application: - assembly of electrical modular equipment and other electrical and electronic devices. - lighting assembly

Request for a quote

DAMEKS

Poland

PCB depanelization is a process step in the production of large-scale assembly of electronics. To increase the throughput of printed circuit board (PCB) and surface mount (SMT) production lines, printed circuit boards are often designed to consist of many smaller individual printed circuit boards that will be used in the final product. This PCB cluster is called a panel or multi-block. The large panel is broken or "depanellated" as a process step - depending on the product, this can be right after the SMT process, after the in-circuit test (ICT), after soldering through-hole components, and even just before the final assembly of the PCBA in the enclosure.

Request for a quote

DAMEKS

Poland

PCB depanelization is a process step in the production of large-scale assembly of electronics. To increase the throughput of printed circuit board (PCB) and surface mount (SMT) production lines, printed circuit boards are often designed to consist of many smaller individual printed circuit boards that will be used in the final product. This PCB cluster is called a panel or multi-block. The large panel is broken or "depanellated" as a process step - depending on the product, this can be right after the SMT process, after the in-circuit test (ICT), after soldering through-hole components, and even just before the final assembly of the PCBA in the enclosure.

Request for a quote

DIAMOND SA

Switzerland

Diamond offers High Temperature (HT) fiber optic metal assemblies developed specially to withstand operating temperatures beyond the range of conventional plastic connectors over extended periods. The HT assemblies rely upon a combination of specialized assembly techniques and materials, together with special fibers with appropriate coatings suitable for deployment in harsh environments. Diamond HT solutions’ benefits extend to temperature applications up to 150° C (302°F) for use in severe conditions within industrial, military, aerospace, off-shore, telecom, and other environments. These add up on top of traditional advantages such as immunity to electromagnetic interference, better environmental stability and enhanced remote sensing compared to traditional electronic sensors. Diamond HT standard assemblies are available in PC and APC version with standard MM or SM fibers. Other configurations are available upon request.

Request for a quoteResults for

Electronics assembly - Import exportNumber of results

40 ProductsCountries

Company type

Category

- Electrical & Electronic Components (8)

- Laser - cutting and welding machines (6)

- Potting equipment (4)

- Printed circuits (3)

- Biomedical equipment (2)

- Electronic components (2)

- Fasteners, metal (2)

- Bearings - ball, needle and roller (1)

- Ceramics, refractory (1)

- ELECTRIC EQUIPMENT (1)

- Electric cables (1)

- Electrical components and parts (1)

- Electronic cards (1)

- Electronic optic components (1)

- Engineering - industrial contractors (1)

- Forming - steels and metals (1)

- Infrared tubes (1)

- Mechanical engineering - custom work (1)

- Moulds, precision (1)

- Sheet Metal & Tubes (1)