- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dies

Results for

Dies - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

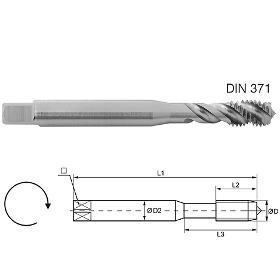

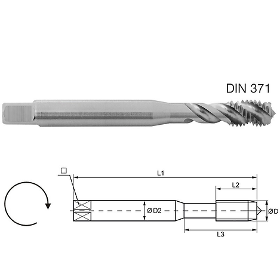

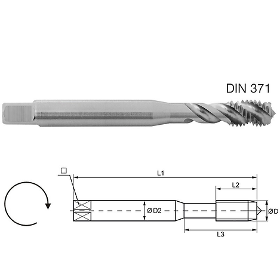

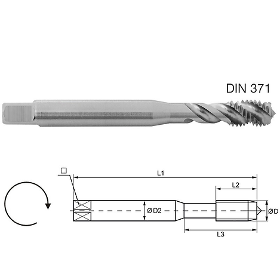

Screw extractor Brand: Baer Tools (Germania) We are available for the questions about this product by phone, email or chat here on the site

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Brand: Baer Tools (Germania) We are available for the questions about this product by phone, email or chat here on the site

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Screw extractor Brand: Baer Tools (Germania) We are available for the questions about this product by phone, email or chat here on the site

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Adjustable tap wrenches, zinc die cast: No. 1: M 1-10 | 1/16-3/8 | G 1/8 No. 2: M 4-12 | 5/32-1/2 | G 1/8 Die sctocks: 20 x 5 | 20 x 7 | 25 x 9 | 30 x 11 | 38 x 14 Tap holder ratchet: M 3-10 | M 5-12 Thread pitch gauge Screw extractor Brand: Baer Tools (Germania)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

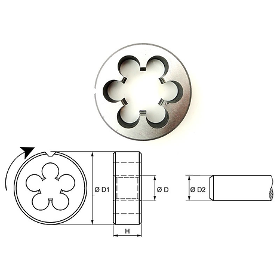

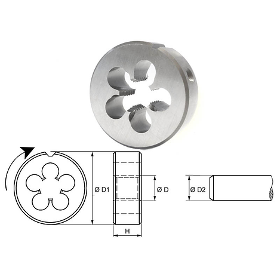

Round die. Metric, ISO DIN 13. HSS. DIN 223. Tolerance ISO-6g. Left-hand. Up to 750 N/mm2. Professional thread cutting Thread standard: Metric, ISO DIN 13 Type: Round die Application: Left-hand Material of product: HSS Spiral entry: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 750 N/mm2 Standard: DIN 223 Tolerance: ISO-6g Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut.

Request for a quote

C.B.C. SRL

Italy

The horizontal cabinet is perfect for efficiently managing and keeping in order the cutting dies used in leather goods and shoe factory. The ideal position is in the storage department. An operator will provide the cutters with the dies that will be used in the work shift. The cabinet is made of galvanised steel, with a white painted top. Equipped with 27 drawers of 35 mm with full-extension ball bearing slides with a capacity of 30 kg. All cabinet are 140 cm high and 57 cm deep. Different widths are available, depending on the space available in the company and the type of dies to be stored. It is possible to insert different combinations of drawers depending on the objects to be inserted, just as it is possible to customise the cabinet. Supplied already assembled on a pallet. Product data CO27_04_01cm 36x57x140 CO27_07_01cm 62x57x140 CO27_09_01cm 88x57x140 CO27_12_01cm 114x57x140 CO27_15_01cm 145x57x140

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

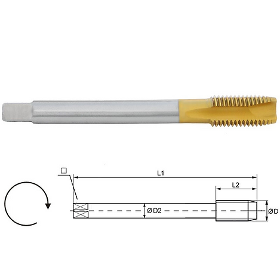

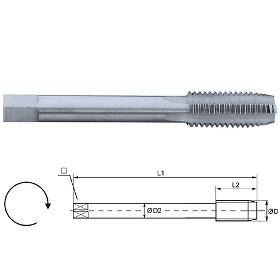

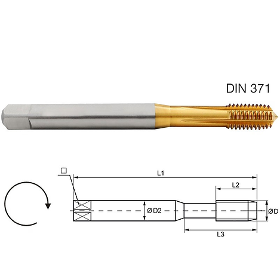

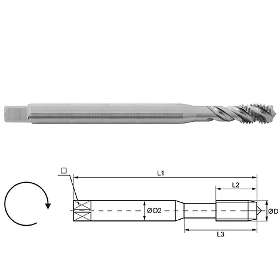

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite,

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

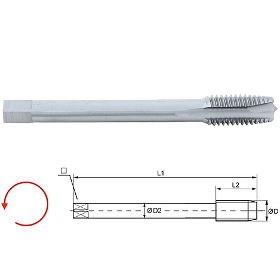

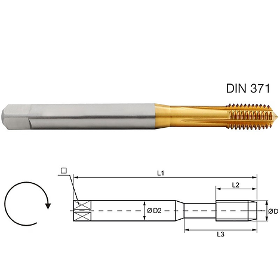

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Left-hand Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materialsCorrect lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

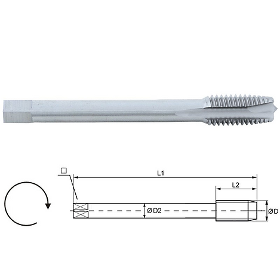

Thread standard: Metric Fine, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 374 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants. Brand: Baer Tools (Germany)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

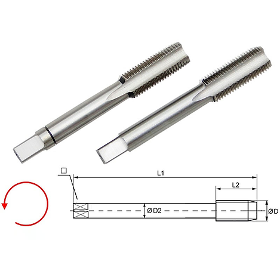

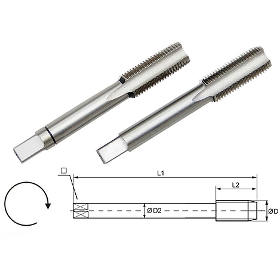

Thread standard: Metric Fine, ISO DIN 13 Type: Hand tap, Form C, for through and blind holes, with straight flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: no For materials: Wear resistant steel Tensile strength up to: 1000 N/mm2 Standard: DIN 2181 Tolerance: ISO2/6H Set of 2 taps (taper, finish). Two-piece hand taps- sets are used for fine threads with a smaller pitch than with coarse thread, as the thread profile surface is smaller than with coarse threads and the force effects on the taps are smaller. The advantage of two-piece hand taps is that the respective parts of a set share the cutting power: The taper tap (No. 1) (marked with a ring) removes 65 per cent of the thread profile and the and brings the thread into shape. The finishing tap (No. 3) has no ring marking and cuts the remaining thread profile to produce the 100% full and usable thread.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Hand tap, Form C, for through and blind holes, with straight flutes Application: Left-hand Material of product: HSSG Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 2181 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Set of 2 taps (taper, finish). Two-piece hand taps- sets are used for fine threads with a smaller pitch than with coarse thread, as the thread profile surface is smaller than with coarse threads and the force effects on the taps are smaller. The advantage of two-piece hand taps is that the respective parts of a set share the cutting power: The taper tap (No. 1) (marked with a ring) removes 65 per cent of the thread profile and the and brings the thread into shape. The finishing tap (No. 3) has no ring marking and cuts the remaining thread profile to produce the 100% full and usable thread.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Hand tap, Form C, for through and blind holes, with straight flutes Application: General use Material of product: HSSG Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 2181 Tolerance: ISO2/6H Set of 2 taps (taper, finish). Two-piece hand taps- sets are used for fine threads with a smaller pitch than with coarse thread, as the thread profile surface is smaller than with coarse threads and the force effects on the taps are smaller. The advantage of two-piece hand taps is that the respective parts of a set share the cutting power: The taper tap (No. 1) (marked with a ring) removes 65 per cent of the thread profile and the and brings the thread into shape. The finishing tap (No. 3) has no ring marking and cuts the remaining thread profile to produce the 100% full and usable thread.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric Fine, ISO DIN 13 Type: Short machine tap Form D, for through and blind holes Application: General use Material of product: HSSG Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 800 N/mm2 Standard: DIN 2181 Tolerance: ISO2/6H Efficient internal thread cutting. The short structural type makes this tap usable by machine and hand. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants. Brand: Baer Tools (Germany)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

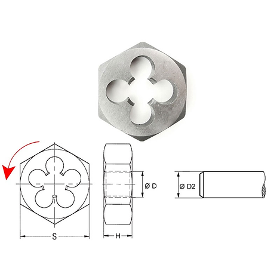

Thread standard: Metric, ISO DIN 13 Type: Hexagon die nut Application: Left-hand Material of product: HSS Spiral entry: no For materials: Non abrasive materials Tensile strength up to: 800 N/mm2 Standard: DIN 382 Tolerance: ISO-6g Left-hand (counter clockwise rotation). For repairing and cleaning of damaged threads. For use in awkward places. The hexagon die nut is particularly advantageous for repairs, as it can be moved with ring or open-end spanners, making it easier to reach inaccessible places. Thiscutting tool has an external hexagon and - depending on the size - has three or more cutting edges inside. The holes between the cutting edges take up the chips, roll them and carry them away. Hexagonal die nuts are used to cut screws, nuts and threaded rods in everyday use. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

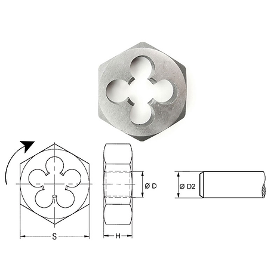

Thread standard: Metric, ISO DIN 13 Type: Hexagon die nut Application: General use Material of product: HSS Spiral entry: no For materials: Non abrasive materials Tensile strength up to: 800 N/mm2 Standard: DIN 382 Tolerance: ISO-6g For repairing and cleaning of damaged threads. For use in awkward places. The hexagon die nut is particularly advantageous for repairs, as it can be moved with ring or open-end spanners, making it easier to reach inaccessible places. Thiscutting tool has an external hexagon and - depending on the size - has three or more cutting edges inside. The holes between the cutting edges take up the chips, roll them and carry them away. Hexagonal die nuts are used to cut screws, nuts and threaded rods in everyday use.Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Round die Application: d25x9 Material of product: HSS Spiral entry: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 750 N/mm2 Standard: DIN 223 Tolerance: ISO-6g Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Round die Application: Undersized diameter Material of product: HSS Spiral entry: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 750 N/mm2 Standard: DIN 223 Tolerance: ISO-6e Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Round die Application: For stainless steel Material of product: HSSE Spiral entry: yes For materials: Stainless steel (INOX, V2A, V4A etc.) Tensile strength up to: 1200 N/mm2 Standard: DIN 223 Tolerance: ISO-6g Special geometry for Stainless steel. Round dies are cylindrical and are used for making external threads in one operation. They have - depending on the size - three or more cutting edges inside. The holes between the cutting edges receive the chips, roll them and discharge them. Dies are used to cut screws, nuts and threaded rods in everyday use. The die holder is used to cut the threads by hand and with the special die holders you can also attach the round die to a tailstock or to a drill. The dies can usually be used on both sides and have a perfect cut. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

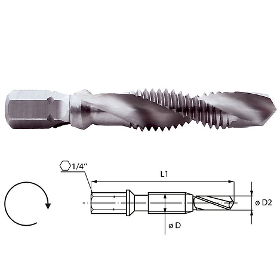

Thread standard: Metric, ISO DIN 13 Type: Combined machine bit tap (core hole drilling and thread tapping) for through holes Application: Combined (core hole drilling and thread tapping) Material of product: HSSG Surface treatment: no For materials: Materials of medium mechanical strength, non ferrous metals and thermoplastics Tensile strength up to: 600 N/mm2 Standard: Factory standard Tolerance: ISO2/6H Combined Bit taps have been designed for drilling, tapping and deburring in one operation using battery-powered screwdriver drills and electric hand drills with right-hand and left-hand rotation, but they are also suitable for thread cutting in a stationary drilling machine. It is possible with this tool to produce through threads up to a maximum threaded depth of 1 x D. They are especially usefull for mounting an dsmall batch production. Take care that the tool and the axis of the hole are exactly aligned and use a suitable cutting oil.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

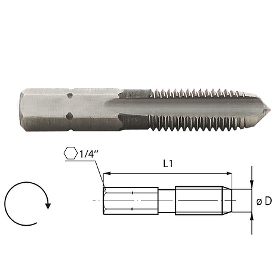

Thread standard: Metric, ISO DIN 13 Type: Machine bit tap Form D, for through and blind holes Application: General use Material of product: HSSG Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: Factory standard Tolerance: ISO2/6H Bit taps have been designed for thread cutting using battery-powered screwdriver drills and electric hand drills with right-hand and left-hand rotation. But they are also suitable for thread cutting by hand or in a stationary drilling machine. Your battery-powered screwdriver drill should have a minimum power of 7.5 Volts. Take care that the tool and the axis of the hole are exactly aligned and use a suitable cutting oil. For thread cutting we recommend using battery-powered screwdriver drills and electric hand drills with lowest rotaionsettings (0 - 450 RPM) and maximum torque settings.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine forming tap Application: Oversized diameter 6GX Material of product: HSSE Surface treatment: TIN For materials: Steel, Stainless steel, Cast aluminum, Coper, Brass etc* Tensile strength up to: 850 N/mm2 Standard: DIN 371/376 Tolerance: ISO3/6GX Tolerance ISO3/6GX – Thread with large clearance. The Forming tap has improved geometry for an optimal processing of a big range of materials. The lubrication grooves provide the necessary lubrication to depths of 2.5 D. Advantages: no chips up to 20 times longer lifetime (compared to taps) same forming tap for through hole and blind hole wide range of materials can be processed intersection of the thread is impossible no pitch or flank angle errors increased strength of the thread through material deformation higher surface quality much higher cutting speed Please be aware to reach enough cutting speed, so that the material can optimally plasticized. Only for machine use.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine forming tap Application: General use Material of product: HSSE Surface treatment: TIN For materials: Steel, Stainless steel, Cast aluminum, Coper, Brass etc* Tensile strength up to: 850 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6HX The Forming tap has improved geometry for an optimal processing of a big range of materials. The lubrication grooves provide the necessary lubrication to depths of 2.5 D. Advantages: no chips up to 20 times longer lifetime (compared to taps) same forming tap for through hole and blind hole wide range of materials can be processed intersection of the thread is impossible no pitch or flank angle errors increased strength of the thread through material deformation higher surface quality much higher cutting speed Please be aware to reach enough cutting speed, so that the material can optimally plasticized. Only for machine use.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

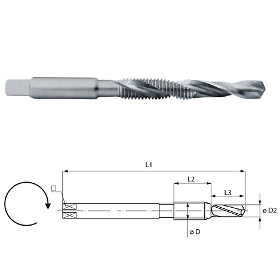

Thread standard: Metric, ISO DIN 13 Type: Combined machine tap (core hole drilling and thread tapping) Application: Combined (core hole drilling and thread tapping) Material of product: HSSE Surface treatment: no For materials: Materials of medium mechanical strength (alloyed and non-alloyed steels up to 600 N/mm², Malleable cast iron, Graphite cast iron, Copper, Brass, Aluminium, Aluminium-magnesium alloys, Zink alloys, Red bronze, Electron metall, Pressure-cast zink) Tensile strength up to: 600 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Combined machine taps enables the user to produce the tapping drill hole and the through thread in one operation without any tool changing. The tool incorporates a twist drill before the thread-tapping part. It is possible with this tool to produce through threads up to a maximum threaded depth of 2 x D. It is sensible to use this tool on machines possesing an RPM switchover facility for drilling and tapping.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

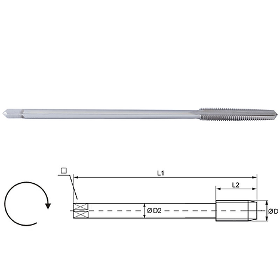

Thread standard: Metric, ISO DIN 13 Type: Machine nut tap Application: General use Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 850 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Maschine Nut tap for through holes with long shank for taking some thread cutted nuts. For thread depth up to 1,0 times diameter. Also useable for thread cutting in awkward places. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Undersized diameter 4H Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO1/4H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Fine Tolerance 4H (ISO1) for close fit bolt connection. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Oversized diameter 6H+0.1mm Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H+0.1mm Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. + 0,1 mm oversize for electroplating allowance ≈ 25 µm thickness. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Oversized diameter 7G Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO3/7G Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Tolerance 7G – allowance for distortion caused by heat treatment. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Oversized diameter 6G Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO3/6G Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Tolerance ISO3/6G – Thread with large clearance. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Overlengthed (long shank) L=150 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quoteResults for

Dies - Import exportNumber of results

86 ProductsCountries

Company type