- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- systems for coating

Results for

Systems for coating - Import export

HFP BANDSTAHL GMBH & CO KG

Germany

This coating system is mainly used for the coating of cold rolled strip, but can also be applied to other metals. It is applied in the last processing step and enables a special gliding ability and heat resistance on coated surfaces.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Functional and decorative coating systems In addition to coatings for Coil Coating applications and related areas, SI-Coatings GmbH develops and produces individual paints and varnishes for any application. These are technical, functional and decorative coatings.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

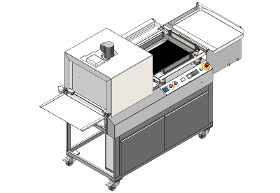

The coaters series type LC were specifically developed for coating tablets. With our coater range, Loedige is one off the technological market leader. The maximised tablet bed surface in the Lödige coater and the maximum number of spray nozzles mean that extremely high liquid volumes can be applied with extremely high air supply volumes within a very short time. The newly designed, particularly low-turbulence air routing ensures a highly efficient and gentle use of dryer air. These features ensure a reliable coating process and short process times. Moreover, the low-turbulence air routing prevents contamination from the very start, thereby reducing the cleaning workload. Modern sensors permit optimisation of the spraying and drying process. Simple yet secure nozzle arm adjustment makes for easier handling.

Request for a quote

FREILACKE EMIL FREI GMBH & CO. KG

Germany

The word “system” refers to the functional entity created from several interconnected components. Today, this term can be applied to a variety of products and services. Again and again, the main challenge is to ensure that all components are coordinated to each other to such a degree that the result is an optimal, comprehensive and qualitatively unique solution. We at FreiLacke have been meeting this challenge with great success for more than 90 years. Traditionally, we develop and produce all coating systems under one roof. Therefore, we do not merely provide you with all the important coating technologies, but also tailor them to your individual needs with regard to coating composition and optics. The advantages: best material properties, consistent colour results (even with varying products and coating types) and the needs-based configuration of individual coatings – and all from one source.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Especially by our research and development work we have succeeded in creating various permanent anti-sticking coating systems. The distinctive deep-drawing properties paired with thermal resistance allow it to be used in a wide range of applications. From façade coating and device covers in industrial engineering to household products, such as sliding surfaces for shavers. There are hardly any limits for our application possibilities.

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

high performance coating of sophisticated parts

Request for a quote

SPANSET SECUTEX GMBH

Germany

The noise levels in pipe and rod raising systems can be very high. A chute lined with secutex pipe modules ensures that noise levels are reduced and that surfaces are protected. The secutex material with inset perforated plates is particularly wearresistant and cushions the movement of pipes and rods very well. The cast sections are attached using drilled attachment holes. Segment sizes and joins are manufactured according to client requests.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Extrusion Coating EC Thermal Imaging System from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes.The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

In coil coating, an organic coating is applied to the surface of a metal strip in a continuous process. The HUEHOCO portfolio includes both decorative and weather-resistant coatings as well as system solutions for a firm bonding of the metal strip with various rubber compounds and/or various plastics. For technical applications, there are also high-temperature resistant and non-stick as well as anti-friction systems, directly rubber- or plastic-coated metal strips. Since 1989 we have been the first company in the world to offer our customers the opportunity to have their goods delivered "endlessly" wound with more than 200,000 metres in a single strip on metal or plastic spools. Depending on our customers' requirements, we can process all wrought aluminium alloys, stainless steels, steel grades and non-ferrous metals available on the market in various degrees of hardness.

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

coating system for high production quantities and individual transportation concepts

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ is a large state-of-the-art xenon flatbed instrument. The 3000 cm2 test chamber is perfect for high volume weathering testing of large flat or 3-D specimen. SUNTEST XXL+ offers a complete set of features ideal for standard testing covering all common industry weathering standards. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and control of Irradiance 300-400 nm / 340nm or 420nm Measurement and control of Black Standard (BST); (Black Panel optional) Measurement and control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Various specimen holders to hold different panel sizes. XenoCal sensors to calibrate BST and irradiance. Large variety of filter systems: coated and uncoated quartz, special UV glass, daylight filter, window glass, Solar ID 65, Solar Standard, to meet various spectral specifications in standards.

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

SolarPaq® temperature profiling systems are designed for specific use in solar photovoltaic (PV) manufacturing. These systems, consisting of user-friendly Insight™ software, Datapaq® Q18 data loggers, stainless steel thermal barriers, thermocouples with PTFE or mineral insulation and accessories, provide you with the tools required to obtain the highest production yields. The Datapaq Q18 logger features rugged, reliable and accurate data acquisition circuits, clear status indicators and an intelligent battery management system. It also features start/stop buttons, time or temperature trigger, memory capacity of 300,000 readings and measures wide temperature ranges from -200°C to 1370°C/-328°F to 2498°F. SolarPaq Profiling System for CiGs Panel Coating SolarPaq temperature profiling system for CiGs Panel Coating monitors the glass substrate as it passes through the vacuum coating process. Its core, the DQ1840 datalogger, is housed

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Customers worldwide use Datapaq® temperature profiling and monitoring systems with their powder coating equipment in automotive and industrial powder coating to optimize product quality, reduce waste and prove compliance with ISO9000. When standard and specialty systems will not meet your exact application requirements, Datapaq will build a custom system using Insight™ thermal profiling software, an extensive range of custom barriers and thermocouples, as well as the Datapaq DP5 and Datapaq TP3 data loggers. In addition, Datapaq offers a complete thermal profiling system for real-time data analysis -TM21 Radio Telemetry System. Oven Tracker Insight Software Datapaq powerful Insight analysis software has been designed specifically to convert raw temperature data into meaningful information that can be used to understand, control and optimize your cure process. Complex calculations are simplified, allowing quick and comprehensive analysis.

Request for a quote

GRÜNING & LOSKE GMBH

Germany

lastic and strong adhesive and sealant on polyurethane (PUR) basis. For bondings and sealings on metals, many plastics, ceramic, wood, glass, stone, etc.. Applications: Tank and apparatus construction, Car body, freight container and vehicle construction, Ventilation and air conditioning, Pipeline and fittings construction, Energy and electrical industry, Insulating technology and in many areas of plastic technology and wherever silicone is not suitable. Properties: Can be painted over and sanded after curing, Odourless curing, Resistant to weathering and UV, Excellent aging resistance, Resistant to fresh water and saltwater, Stable, pasty and Silicone-free. A better adhesion is achieved by using suitable WEICON adhesion agents. With suitable paint coating systems (except alkyd resin paints). Available in white, grey and black.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RHEIN-CHEMOTECHNIK GMBH

Germany

Application: Inline after curing or after surface treatment with active UV-curing, roller application, available as 1K- or 2K-system UV-curing base coat for two-layer UV-curing coatings 100% UV-curing polymer coating, high adhesive bond to the concrete surface, strong colour-intensifying effect, high alkaline and water resistance, high block resistance

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

In addition to the product range of classic cold rolling mills, we can also offer our customers electrolytically galvanized strip. The zinc coating offers excellent corrosion protection: In cooperation with our customers, we have developed a product that solves the problem of zinc abrasion in the processing of galvanized strips - ZPL (Zinc Plus Paint). An organic coating system is applied immediately after electrolytic galvanizing. This results in a colourless, uniform, highly lubricious layer with a dry film thickness of 0.50 - 3.00 µm, which can of course also be supplied in any desired colour. ZPL offers the following advantages: Further improvement of corrosion protection Excellent sliding properties, preventing zinc abrasion in the tool Reduced tool wear Longer tool life Oil-free processing is made possible Coating and printable layer with "Anti Finger Print" properties

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

3D coating means that the visible surface and all sides of a component are coated with a film with precise contours, while theunderside remains completely free

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

The Matthews’ 10 watt and 30 watt C02 laser coding system permanently marks coated paper, plastics, rubber extrusion, and glass—making it ideal for a variety of industries. An affordable alternative to small character inkjet technologies, it cleanly marks alphanumeric text, date and time codes, serial numbers, barcodes, 2D codes and graphics.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

The CUSTOMline hot melt machine is the top solution for customized casting requirements. It is configured specifically according to customer requirements and can handle complex casting tasks with exceptional precision and efficiency. This machine is ideal for special applications where standard solutions are not sufficient. With the CUSTOMline you get a casting machine that is tailored precisely to the specific needs of your production process in order to achieve optimal results. product [hot melt application systems, hot melt coating machines for paper, hot melt, hot melt adhesives, hot melt packaging, hot melt adhesives, special machines for adhesive processing, hot melts, machines for gluing, machine for gluing, melt casting technology with hot melt, hot melt coating, gluing machines, special machines for casting, sealing, foaming, gluing, special packaging machines]

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

In order to get started with low pressure molding technology, for prototyping new projects and producing small series, Labline offers a selection of small devices tailored to the requirements of low pressure molding technology. The basis here is the hand-held casting gun with a 0.2l tank for filling the casting materials in granulate form. In order to achieve process stability and reproducibility even with this manual processing, a timer can be connected. Two different clamping devices are available for convenient handling of sample and pre-series tools. product [hot melt application systems, hot melt coating machines for paper, hot melt, hot melt adhesive, hot melt adhesives, special machines for adhesive processing, hot melt packaging, machine for gluing, machines for gluing, hot melts, gluing machines, hot melt coating, gluing machines for labels, laboratory coating machines, systems for adhesive technology]

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

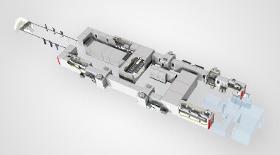

Schlötter Systems Dr.-Ing. Max Schlötter GmbH & Co. KG is among the leading manufacturers of electroplating systems and surface treatment facilities. With more than 1,000 systems realized since 1957, we draw upon a wealth of experience in production-ready solutions. At Schlötter, we leverage our expertise in systems engineering and surface technology to precisely tailor each system to the coating processes required by our clients. We design and manufacture rack, barrel, and manual systems, modernize facilities, and support our customers with our systems technology services throughout the long lifespan of our systems. Rack systems Barrel systems Manual systems Electroplating systems Anodizing systems Cleaning and pickling systems Chemical systems Printed circuit board systems Plastic electroplating systems Schlötter Systems in All Surface Technology Industries Schlötter systems are utilized for a wide range of surface technology applications.

Request for a quote

FUCHS GMBH & CO. KG

Germany

Our breadings are based on seasoning with a fat coating. They guarantee optimum, stable appearance during the full shelf life. We distinguish between breadings for meat and for convenience specialities. Breadings for fish For breading and seasoning of fish of all kinds. Examples are herb, paprika or curry coatings. These dry seasonings Are suitable for oven-baking and pan-frying Guarantee optimum, stable appearance during the full shelf life. Can be individually adjusted for salt content Can be applied by a flour dredging or dry coating system. Breadings for baking for breading convenience specialities. Various types, including gluten-free, are available and can be offered with and without seasonings.

Request for a quote

EICHSFELDER SCHRAUBENWERK GMBH

Germany

Hook for tail gate locking system (partial plastic coated)

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

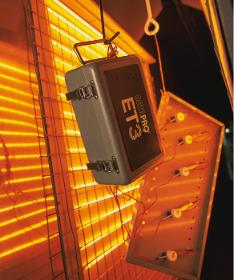

DATAPAQ temperature profiling systems include high-accuracy industrial-strength data loggers, analysis software, thermal barriers, and thermocouples. EasyTrack3 Thermal Profiling System is designed for temperature profiling of powder coating ovens and products. With choice 4 or 6 measurement channels, the EasyTrack3 system allows you to monitor and record product temperatures in your curing oven. Use the detailed temperature profile data to: • Monitor and prove QA • Optimize your powder coating oven performance and save energy costs • Identify potential problems in your powder coating process and correct them quickly and efficiently The range of thermal barriers is designed to match different coating applications or operational needs. These provide dual protection confidence using microporous insulation and phase change technology and maintain logger temperatures at a level to guarantee the accuracy of the temperature measurements recorded.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The automotive industry standard in thermal profiling of paint cure processes Silicone-free technology Multiple oven tests possible before returning to PC Process Pass/Fail at oven exit Up to 16 measurement locations in a single run Hard wired real-time data analysis from batch ovens Fully customizable and easy-to-use Insight analysis software Wide range of thermal barriers & thermocouples to suit your process needs

Request for a quoteResults for

Systems for coating - Import exportNumber of results

52 ProductsCountries

Company type

Category

- Lens products (4)

- Infrared tubes (3)

- Steels and metals - surface treatment and coating (3)

- Pharmaceutical industry - machinery and equipment (2)

- Potting equipment (2)

- Temperature sensing devices (2)

- Varnishing equipment (2)

- Paints and varnishes (1)

- Anti-corrosion coatings (1)

- Coatings, plastic (1)

- Industrial paintings (1)

- Surface treatment - machinery and equipment (1)

- Chemicals - Basic Products & Derivatives (1)

- Concrete products and conglomerates (1)

- Disks, magnetic (1)

- Electrical components and parts (1)

- Electromagnets (1)

- Food Processing (1)

- Industrial resin coatings (1)

- Laser - cutting and welding machines (1)