- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- systems for coating

Results for

Systems for coating - Import export

FREILACKE EMIL FREI GMBH & CO. KG

Germany

The word “system” refers to the functional entity created from several interconnected components. Today, this term can be applied to a variety of products and services. Again and again, the main challenge is to ensure that all components are coordinated to each other to such a degree that the result is an optimal, comprehensive and qualitatively unique solution. We at FreiLacke have been meeting this challenge with great success for more than 90 years. Traditionally, we develop and produce all coating systems under one roof. Therefore, we do not merely provide you with all the important coating technologies, but also tailor them to your individual needs with regard to coating composition and optics. The advantages: best material properties, consistent colour results (even with varying products and coating types) and the needs-based configuration of individual coatings – and all from one source.

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

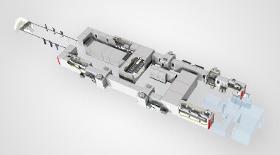

high performance coating of sophisticated parts

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

coating system for high production quantities and individual transportation concepts

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

Schlötter Systems Dr.-Ing. Max Schlötter GmbH & Co. KG is among the leading manufacturers of electroplating systems and surface treatment facilities. With more than 1,000 systems realized since 1957, we draw upon a wealth of experience in production-ready solutions. At Schlötter, we leverage our expertise in systems engineering and surface technology to precisely tailor each system to the coating processes required by our clients. We design and manufacture rack, barrel, and manual systems, modernize facilities, and support our customers with our systems technology services throughout the long lifespan of our systems. Rack systems Barrel systems Manual systems Electroplating systems Anodizing systems Cleaning and pickling systems Chemical systems Printed circuit board systems Plastic electroplating systems Schlötter Systems in All Surface Technology Industries Schlötter systems are utilized for a wide range of surface technology applications.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

EHG electromagnetic holding rods are used in fixture construction, for gripper systems and for a wide variety of tasks in mechanical engineering. EHG holding rods consist of a screwed, two-part system, are double-coated and sealed to IP 65. Max. Operating temperature 60°C Standard voltage 24,48,110V DC Protection class IP 53 ED 100%

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIENER ELECTRONIC GMBH & CO. KG

Germany

Parylene is the short name for the polymer group of poly-para-xylylene. Parylene coatings offer a wide range of benefits. Parylene ... are fully conformal: i.e. they adapt to complex substrate contours such as sharp edges, drill holes or blind holes are pinhole-free from a film thickness of approx. 0.5 µm. are chemically insoluble and resistant to a wide range of chemicals. have very good barrier properties against moisture and chemicals. have a high dielectric strength. have dry lubricating properties (low coefficient of friction). are hydrophobic: contact angle of H2O between 92 ° and 98 °. are transparent between 90 and 96 % in the visible wavelength range (depending on type). are biocompatible: types C and N parylene can be deposited, which can be certified according to USP Class VI, ISO 10993 and FDA.

Request for a quote

FREILACKE EMIL FREI GMBH & CO. KG

Germany

Extra value thanks to energy-efficient powder coatings. Energy-efficient powder coatings are primarily low-temperature powder coatings or fast-reacting powder coatings (NT). Many users of such powder coatings look for the opportunity to lower baking temperatures, thereby achieving direct reductions in oil and gas consumption. However, energy-efficient powder coatings can also increase productivity within the coating system. The baking oven frequently constitutes a bottleneck point in the process. At low baking temperatures, the use of powder coatings can significantly shorten the oven throughput time, thereby increasing the line speed. Take off into the future with new application fields. With energy-efficient powder coatings, you can take advantage of new products and application fields for your company. The range of parts can also be expanded by their usage.

Request for a quoteResults for

Systems for coating - Import exportNumber of results

8 ProductsCompany type