- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electronic assemblies

Results for

Electronic assemblies - Import export

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Optimel is your reliable partner for solutions for encapsulating electrical and electronic assemblies. The innovative Low Pressure Moulding (LPM) technology offers optimal protection against external influences such as moisture, dust and vibrations, thus ensuring the longevity and reliability of your products. The Low Pressure Moulding process or hotmelt moulding process originated in the sealing of cable harnesses in the automotive industry - today it is used in many areas for the protection of electrical and electronic components. At 5-40 bar (in individual cases up to max. 60 bar), processing takes place at a much lower pressure than in the classic hotmelt injection moulding process. This makes it easy to directly encapsulate even sensitive components such as circuit boards, sensors, etc. The cycle times are limited to pure encapsulation

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Component placement requires individual approaches. Our range of solutions covers small series produced by hand, medium-size series using semi-automated wave soldering machines and fully automated production lines for large-scale manufacture. We adjust the level of assembly automation to your project – so that you achieve the best result both economically and technically.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Whether it's manual soldering with robotic support, wave and selective soldering or laser soldering – in all assembly tasks, we are able to use any technique required without a problem. Depending on the component, different soldering technologies offer different advantaged. We will adjust the process individually to your project.

Request for a quote

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

DYMAX EUROPE GMBH

Germany

Dymax GA201 forminplace (FIP)/cureinplace (CIP) gasketing resin is formulated for sealing plastic, glass and metal enclosures, and plated surfaces for automotive door handle, appliance housing, and critical electronic assembly and device applications which require a soft, tackfree, flexible gasket. Features: - Cures with UV/Visible light - Moisture resistant - Chemical resistant - Tackfree cure - Soft, durable after complete cure - Conforms to intricate channels and recesses - Compliant with RoHS directives 2015/863/EU

Request for a quote

DYMAX EUROPE GMBH

Germany

Dymax GA140 forminplace (FIP) and cureinplace (CIP) gasketing resin is formulated for fuel cell, automotive door handle, appliance housing, and critical electronic assembly and device applications which require a soft, tackfree, lowoutgassing, flexible gasket with compression set. Features: - Cures with UV/Visible light - Low outgassing - Cures soft and tack free - Excellent tear resistance - Clear in color - Cures in seconds - Silicone free - Conforms to intricate channels or recesses - Compliant with with RoHS directives 2015/863/EU

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

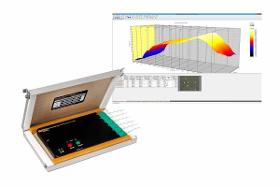

The Datapaq® Reflow Tracker® temperature profiling system travels through the process, enabling you to monitor wave and reflow soldering, as well as vapor phase, selective soldering and rework stations. Comprised of specifically designed thermocouples, data loggers, protective thermal barriers and Insight software, this system will help you optimize product quality, expedite process setup, increase yields and minimize the need for rework. For more details and specifications, download the Reflow Tracker System brochure. Insight Software for Reflow Tracker available in Basic, Standard and Professional versions Insight software is an easy-to-use analysis package designed by Datapaq to meet the needs of the electronics assembly industry. With a typical reflow soldering profile lasting only six minutes, users don't want to spend additional time analyzing the profile. Insight Software ensures that the user is presented with a detailed analysis immediately and it comes

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Digital Torque Gauge with pull-out LC Display High precision handheld digital gauge with integrated LC display to measure small torque. Ideal for torque measurement like rotating torque, click torque of precision machinery, electronic devices, and various assembly components. The digital display simply slides out of the housing and is attached with a curly cord. Use the optional testing stand to secure the gauge while testing or add fixture to secure your test piece. Combined with Measurement Stand (#808), it can be fixed to use as torque screwdriver checker, et al. ATGE-G series devices are manufactured for the global market and offer a selection of SI, metric and American units of measurement. Equipped with SI calibration as standard, optionally available with calibration in anglo-saxon (ozf·in) or in metric (gf·cm) units.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Up to 60 rivets per minute! – Endorsed by major customers! GESIPA® speed rivets are a cost-effective alternative to automation. Speed rivet technology is a joining method that requires access from only one side and which enables fast cycle times thanks to the preloaded rivets and automatic feed. Advantages • Large grip range • Reduced variation • Optimum hole filling capabilities and bearing stress • Ideally suited for transferring shear strengths with moderate clamping force • Ideal for: — LED light strips — Electronic/pcb assembly — Lightweight sheet metal structures — PC housings — Rating plates — Blind holes

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

The CUSTOMline hot melt machine is the top solution for customized casting requirements. It is configured specifically according to customer requirements and can handle complex casting tasks with exceptional precision and efficiency. This machine is ideal for special applications where standard solutions are not sufficient. With the CUSTOMline you get a casting machine that is tailored precisely to the specific needs of your production process in order to achieve optimal results. product [hot melt application systems, hot melt coating machines for paper, hot melt, hot melt adhesives, hot melt packaging, hot melt adhesives, special machines for adhesive processing, hot melts, machines for gluing, machine for gluing, melt casting technology with hot melt, hot melt coating, gluing machines, special machines for casting, sealing, foaming, gluing, special packaging machines]

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Special machines for the automotive and supplier industry Machine system for low pressure molding - electronics encapsulation The FLEXline series offers maximum flexibility through the modular design of various variants as well as expanded options for implementing special functions. The adaptation or addition of individual mechanical components is just as possible as special programming or integration into a complete production line. In addition, various application systems are available, including hot runner systems with different nozzle geometries and arrangements. The melting units can be optimally tailored to the requirements of the respective project with different melting and conveying systems and, if project requirements differ or change, can be replaced at any time using our "plug-and-play" system. Extensive peripherals and additional options round off the system. The FLEXline can therefore be optimally tailored to the requirements of the respective project.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Special machines for the automotive and supplier industry Machine system for low pressure molding - electronics casting The BASEline series combines a compact design and convenient operation and can be used optimally for the majority of low pressure molding projects. Various mechanical components can be put together depending on requirements. The adapted melting device with double-acting piston pump, 4l tank volume and a melting capacity of approx. 1kg/h enables optimal processing of small to medium shot weights and/or quantities. The available clamping force of 9/12kN is suitable for casting surfaces up to approx. 3,000mm². By using the Siemens S7-1200 control with touch panel, the series offers the same ease of use as the larger series.

Request for a quote

SEIFERT ELECTRONIC GMBH

Germany

Our thermal management and insulation products are far from being just interim solutions. The Thermal Interface Materials (TIM) from Seifert electronic GmbH ensure optimal thermal connection between heat sinks and the components to be cooled. As electronic assemblies become increasingly compact, even a tiny gap between individual components can disrupt the necessary heat dissipation. Air pockets between the heat sink and the component being cooled hinder the optimal thermal connection. Possible consequences include temperature overload, which can lead to overheating in the worst-case scenario. Thermal management and insulation products act as connectors between the heat sink and the electronic component being cooled. They fill every tiny gap between the heat sink and semiconductor with thermally conductive material. This ensures optimal thermal connection and prevents any heat buildup.

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

If you want to have a device completely assembled, you've come to the right place. It does not matter whether you only need a small number of items or series production. We derive the processes and assembly instructions from a first joint workshop. In this way we can procure the important components, assemble the device and then test it. Your product will be assembled according to your requirements. On request, we can assemble under clean room conditions, assemble only individual components or prepare the device for final assembly on your premises. When assembling devices, we can work with methods such as press-fit technology or, for example, secure components by gluing. Your advantages with A + B Electronic -Device assembly according to your requirements -We are not just a service provider, but a technology partner: A + B Electronic thinks your project with you and together we can bring it to series production successfully

Request for a quote

RAFI ELTEC GMBH

Germany

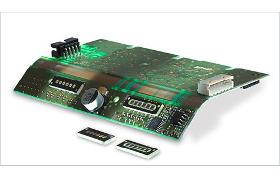

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. At RAFI Eltec, we test the quality of our products across all manufacturing processes. By performing individual tests and integrating fully automatic tests in combined assembly and testing lines, we achieve targeted and effective test cost reductions. For this purpose, we insist on the most cutting-edge technologies and high-quality equipment. Testing technologies - Pull test for chip-on-board - Automatic optical inspection - Flying probe - In-circuit test - Boundary scan test - Function test - Burn-in test and run-in test - Temperature shock test - Temperature humidity test You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Providing maximum quality for your ideas and products is what motivates us. To achieve this, we introduce our high quality standards to projects even before manufacturing begins. As a result of our expert analysis of customer data, potential pitfalls are eliminated in advance. We document sample productions in detailed test reports and discuss them with you. Due to our state-of-the-art testing technology and our in-house test equipment construction, we increase the quality of your production while simultaneously reducing logistics costs. You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Even if the production process uses NoClean fluxing agents, special requirements sometimes call for a special cleaning process: with our state-of-the-art ultrasonic cleaning system, we reduce ionic residual contamination to a minimum. As a result, the cleaned assemblies can be quickly and safely further processed. Our focuses: - Assembly cleaning - Checking for assembly cleanliness You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process. We expertly answer all your questions and achieve our mutual goal: your satisfaction and success.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Efficient production processes and reliable execution of the overall implementation are characteristic for RAFI Eltec. As a result of our many years of experience in energy measurement technology and in radio and network applications, we have accumulated unique production and testing expertise. This is also naturally to your advantage in regard to the final assembly of your devices. Final assembly - Assembly presses and screw fittings - Ultrasonic welding - Adhesive robots - Semi-automatic and fully automatic assembly - Automated testing - Laser or inkjet printing technologies - Leak tests - Box build You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process.

Request for a quote

RAFI ELTEC GMBH

Germany

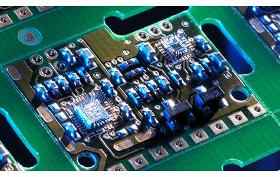

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. RAFI Eltec operates 5 fully automatic SMD high-speed, precision assembly lines with nitrogen reflow soldering technology. Our focus: - BGA, µBGA, CSP - QFN, Finepitch - 0201 - Novel components - Package-on-package - Automatic optical inspection Providing maximum quality for your ideas and products is what motivates us. To achieve this, we introduce our high quality standards to projects even before manufacturing begins. As a result of our expert analysis of customer data, potential pitfalls are eliminated in advance. We document sample productions in detailed test reports and discuss them with you. Due to our state-of-the-art testing technology and our in-house test equipment construction, we increase the quality of your production while simultaneously reducing logistics costs.

Request for a quoteResults for

Electronic assemblies - Import exportNumber of results

20 ProductsCountries