- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cleaning systems

Results for

Cleaning systems - Import export

GSW SCHWABE AG

Germany

Cleanliness pays off over time. GSWNozzles prove this on a daily basis. Always exactly fitting the application, these components free any machine of burrs, oil and dust – quickly and with little noise.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

The WIWOX® VERSA GENIUS+ ultrasonic cleaning system enables individual, demand-oriented mould and parts cleaning. The modular design allows adaptation to almost all process requirements. Later expansion or automation is possible at any time. WIWOX® VERSA GENIUS+ ultrasonic cleaning systems consist of washing, jet, rinsing and drying modules as well as the corresponding accessories. The spectrum ranges from individually operated cleaning basins to fully automated, multi-stage cleaning lines. WIWOX® VERSA GENIUS+ sets new standards in modern plant design. Well thought-out details in the area of guiding the cleaning medium, agitation and process control ensure a flexible and energy-efficient process sequence that meets the requirements. You can convince yourself of the economic efficiency of the system by extensive cleaning tests in our test laboratory. The bath care accessories also play an important role in the cleaning result, the uniform process flow and the operating costs.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® CORUS HD ultrasonic systems have been specially designed for cleaning high-quality moulds and precision tools. In maintenance these replace the labour-intensive and often ineffective manual cleaning. The ultrasonic cleaning process can be used for all metal moulds, in particular tools for injection moulding, extrusion, rubber processing as well as aluminium and gravity die casting. A typical structure consists of three stages: 1. cleaning, 2. rinsing and 3. passivating. The usable dimensions are matched to common mould sizes. The workpieces to be washed are placed in the tank either with the aid of a washing basket or with a lifting beam. Our ErgoStation is recommended for manual rinsing, drying and post-treatment. The working area is completely enclosed, brightly illuminated and ventilated. Operation is safe and simple, as the moulded parts are loaded laterally through a sliding door and held by a lifting device during treatment.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® VIVERK are single and multi-stage spray chamber cleaning systems for aqueous cleaning, pretreatment and degreasing of tools and parts. Loading takes place via an extendable platform, which can be loaded at an ergonomic working height. The workpieces are mechanically cleaned by means of pump pressure in the spray chamber process. The temperature-controlled washing liquid is sprayed onto the workpiece via a spray frame.The washing plant is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

ROLLON GMBH

Germany

International patent registered for the CLEAN ROOM SYSTEM line (DIN EN ISO 14644-1) The CLEAN ROOM SYSTEM units are linear actuators with belt driven transmission and are specifically designed for Clean Room applications They are supplied with a certificate issued by the IPA Fraunhofer Institute in Stuttgard, which certifies compliance with class ISO 3 (DIN EN ISO 14644-1), or with class Fed Std 0.01 (FED 209 E). The system prevents particles from being discharged in the environment where the linear unit is located. This has been achieved by using a special straight seal that closes the horizontal opening where the slider moves, as well as by the operation of a 0.8 vacuum pump connected to 2 vacuum pipes located inside the drive head and the idle head. The system allows vacuum to be generated inside the unit so that any particles released when the system is operating are sucked towards the air filtration areas. Clean Room System linear actuators components are all made of...

Request for a quote

IGUS® GMBH

Germany

Other information E3.10 Inner height hi: 10 mm Inner widths Bi: 20 - 60 mm bending radii R: 15 - 48 mm Pitch: 16,7 mm E-Chain®. E3.15 Inner height hi: 15 mm Inner widths Bi: 20 - 60 mm bending radii R: 32 - 75 mm Pitch: 16,7 mm E-Chain®. E3.22 Inner height hi: 22 mm Inner widths Bi: 20 - 60 mm bending radii R: 44 - 75 mm Pitch: 16,7 mm E-Chain®. iF -Design Award 2005 IPA classification - Report IG0704-400:: ISO Class 1, according to DIN EN ISO 14644-1 for system E3, Series E3.15.040.075.0 at v = 0,5 m/s, 1 m/s, 2 m/s Other information E3.10 Inner height hi: 10 mm Inner widths Bi: 20 - 60 mm bending radii R: 15 - 48 mm Pitch: 16,7 mm E-Chain®. E3.15 Inner height hi: 15 mm Inner widths Bi: 20 - 60 mm bending radii R: 32 - 75 mm Pitch: 16,7 mm E-Chain®. E3.22 Inner height hi: 22 mm Inner widths Bi: 20 - 60 mm bending radii R: 44 - 75 mm Pitch: 16,7 mm E-Chain®. E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Opening and closing of the E-Chain®. Interior separation and strain reliefs. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. E3 system E3: System for highly dynamic applications The cycle times are always shorter in the automation, whereas the requirements in noise reduction, service life, vibration dampening are always higher. For this wide area of small E-Chain®, igus® now introduces the E3 system product range that completely caters to these requirements: Extremely low noise operation (max. 38 dB(A)). The resilient element replaces pins and bores as fastener Modular chain made of three elements Cost-efficient crossbar and separator "on the band" Quicker and easier access to cables by the zipper system Good stability through stable, interlocked links Easy to shorten or lengthen Ideal for flat cables Accessories: Separators, integrated strain reliefs, mounting brackets Typical industrial sectors and applications Production and processing of semiconductors Optics Automatic insertion machines Materials handling technology Measuring technology Printer and plotter Clean room application General mechanical engineering iF -Design Award 2005 IPA classification - Report IG0704-400:: ISO Class 1, according to DIN EN ISO 14644-1 for system E3, Series E3.15.040.075.0 at v = 0,5 m/s, 1 m/s, 2 m/s

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

The WIWOX® USm Ultrasonic cleaning tanks enable individual, demand-oriented surface treatment in a single or multi-stage process. The modular design allows adaptation to almost all requirements and subsequent expansion or automation is possible at any time. Aqueous cleaning at temperatures between 60° and 80° C ensures absolute degreasing and particle removal. Organic or inorganic residues such as polishing paste, paint, plastic, release agents, oil carbon or lime can be easily removed by using the right cleaner. The workpieces are cleaned within a few minutes. The cleaning result is always perfect and reproducible. The subsequent rinsing process is followed by stain-free post-cleaning or preservation. The WIWOX® ultrasonic cleaning process can be used for all steel moulds as well as brass and copper parts. Especially tools for injection moulding, extrusion, rubber processing, aluminium die casting and gravity die casting.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® PYRO paint stripping and decoating oven for particularly large and heavy batches. Particularly powerful furnace technology for the highest demands. With state-of-the-art IPC control and industrial burner technology. This furnace series enables clean, reproducible process parameters as well as state-of-the-art exhaust gas treatment.

Request for a quote

GSW SCHWABE AG

Germany

selfadherent blowout fitting through magnetic base amount of escaping air adjustable finely via a ball valve with position stable uniflextube for accurate positioning also suitable for cooling liquid

Request for a quote

GSW SCHWABE AG

Germany

ideal for producing an air curtain or for drying extensive areas high blowing power at significantly reduced noise development flexible in user applications

Request for a quote

GSW SCHWABE AG

Germany

high blowing power at significantly reduced consumption of compressed air and lower noise development for every case of use the right passage ideal for blowing out punch parts Heat Resistance 90° C

Request for a quote

GSW SCHWABE AG

Germany

the good value for money choice for all standard applications high blowing power at significantly lower noise development flexible in user applications low air consumption Heat Resistance 90° C

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Thermal cleaning in the WIWOX® IGS thermal system at up to 500° C removes all organic residues, even from fine bores. Depending on the melting and decomposition point of the residues, they are either melted or pyrolysed. The resulting exhaust air during the carbonization phase is burned in the afterburner chamber at over 850° C. Cleaning in the pyrolysis process requires subsequent post-cleaning. Inorganic components, oxidation residues, corrosion, etc. remain on the tool surface and must be removed. The ultrasonic process with acidic or alkaline cleaning media or the blasting process with organic and mineral abrasives are suitable for this purpose.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

If the service is right, every production plant will work economically for many years. We offer you a qualified repair and maintenance service, even for older machines and third-party products. Our service technicians will look after you quickly and anywhere with fully equipped vehicles. We pay attention to the good training of our personnel. Experienced mechanics, locksmiths or electronics specialists offer you every support to ensure the perfect functioning of the delivered systems. Our plant service – also for older machines and other manufactures!

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® Spintec top loader spray chamber washing systems are the solution for fast parts cleaning in maintenance! The parts to be cleaned are placed in the washing basket of the system from above. During the washing process, cleaning fluid is sprayed onto the parts from below, above and from the sides. The basket rotates inside the machine, resulting in an even washing result. The detergent reservoir is located in the bottom of the machine and is also equipped with a heater.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Single and multi-stage spray chamber washing systems for industrial cleaning and degreasing of tools and parts. Loading takes place via an extendable loading platform at ergonomic working height. Before cleaning, the loading basket is loaded and moved into the rinsing chamber. The individual stainless steel washing nozzles can be easily maintained and adjusted according to the application. The motor-driven spraying rotor completely revolves around the loaded parts. The washing system is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

DRESSLER GROUP

Germany

Our production is done in specifically equipped rooms, to rule out the possibility of product contamination from the outside. This includes, for example: special access authorisation, airtight walls and ceilings, windows that cannot be opened, air supply to the rooms being filtered, higher inside air pressure in relation to the outside air, insect lamps to prevent contamination with insects, mandatory protective clothing, shoe covers, gloves and hair covers, written authorisation with documentation for all work or events taking place in the rooms, such as cleaning, conversions, malfunctions. We have specialised in the particular needs of the pharmaceutical, food and health industries. All production takes place under clean room conditions and in compliance with the highest hygiene standards. Some sections are FDA-approved. Food additives are processed in accordance with the HACCP principles and in compliance with the European food hygiene directives and are prepared for dispatch.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This automatic washing & drying system provides high efficient cleaning of elastomers in through-feed method (on option washing with de-ionized, de-mineralized or ultra-pure water possible). Starting from the loading station, the washing drums are conveyed automatically to each washing station (→ station pre-washing → station rinsing → station high pressure cleaning → station high pressure drying) and are finally conveyed to the unloading station after treatment. The dimensions of this system depend on the drum dimensions desired (perforation from 3 - 15 mm possible by choice). Set as our default, the models WD3, WD5 and WD9 are available with different sizes. For industry 4.0 demands, this system is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. Siliconisation or other coating of elastomers is possible on option.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® Insulator Heaters are used in flue gas cleaning systems for preheating the insulators and as protection of the equipment against condensation and freezing during shutdown periods

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® 340 is a weakly alkaline cleaning agent for grease, oil and oil carbon soiling. Very suitable for pre-cleaning or basic cleaning of soiled steel, cast iron and non-ferrous metal or plastic parts in an ultrasonic bath or in a spray cleaning system. After cleaning and without water rinsing, the parts are temporarily protected against corrosion. The final drying can be accelerated by blowing off with compressed air, a warm air flow or treatment in a drying cabinet. WIWOX® 340 can be used in a concentration of 5 – 7 %. Dilution with water depends on the degree of contamination and the intended exposure time. The bath should have a temperature of approx. 60° C. The bath should be kept at a constant temperature. In the field of precision mechanics, longer exposure times are possible depending on the degree of contamination.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The STAUFF Clean System comprises of a pneumatic launcher and a range of specially designed nozzles and projectiles. The launcher uses standard industrial compressed air pressure between 6 and 8 bar / 87 and 116 PSI to propel a foam projectile through the nozzle and into the pipe, tube or hose bore to have their inside surface cleanedfrom any unwanted contamination. This provides a safe and environmentally friendly tool that requires little formal expertise to operate and apply. The launcher is the part of the system that controls the air supply to propel the projectile from start to finish of the cleaning job. The nozzles are specially designed to affect an airtight seal on any pipe, tube or hose with or without end fittings. Its main purpose is to compress the foam projectile allowing it to enter the internal diameter of the pipe, tube or hose to be cleaned. The projectile is the part of the system that does the cleaning: The foam projectile is sized to be approximately 15 %...

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

This cleaning machine "Rhönrad" is the ideal choice for the cleaning of parts with cropped areas, which needs to be moved during the cleaning process (rotate or swivel around the horizontal axis). Through the use of a special height adjustable lock-system also smaller baskets can be used without problems. Multi tank systems for special subsequent processes can complemented as well as drying and bath treatment systems. The PERKUTE-System: economically - environmental - effektive Basic unit § Stainless steel version § Compact and sturdy construction § Modern design § Powerful washing pump § High permissible basket load § Low water pressure switch as dry-run protection for pump and heating elements § Tank cover in the return flow, filter baskets incl. § Programmable Siemens S7-1200 touch panel control § Complete machine casing in modern design § Loading ramp incl. collection tray and grating for manual loading § Service hatch for cleaning activities § Mountings for fork-lift §...

Request for a quote

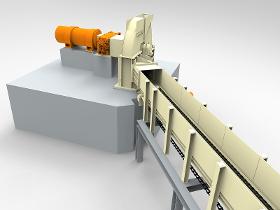

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The line for tree-length logs is designed for the processing of whole logs with lengths of up to20 meters: With the log feed, debarker, washingsystem, dosing system all the way to the highlyecient disc chippers, the production of highquality chips is guaranteed Key featuresFeeding of the wood from the truck or storage areaLarge gantry or rotating cranes for loads of up to 30 metric tons of woodExtremely robust longitudinal chain conveyors or chip chutesLarge conveying cross-sections and laterally arranged chutesDrum debarkersChipper feeding onveyors for large throughputs Metal sensor and roller conveyor cleaning systemDisc chipperAdvantagesGentle de-barkingMinimal ne material content among chipsHigh safety against jamming of logs

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

In the PERKUTE cleaner - range you will find the suitable cleaning agent for each application. The alkaline, neutral and acid PERKUTE cleaning agents are ideal for: - Cleaning and degreasing - Conserving - Passivating - Phosphating All detergents are environmental friendly, biodegradable (in accordance with washing and cleaning agent law). We would be happy to send you a product sample and offer a cleaning test free fo charge with your parts. As a completment to our system - cleaning agents, we also offer: - Antifoaming agents - Emulsion splitting agents - Machine cleaniers We will be happy to advice you!

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Paint stripping system Clean-o-mat RC - E The proven and solid single-chamber system for the automatic and efficient paint stripping of large and small components. The paint stripping of the products is carried out in the spray process using an appropriate organic bio stripper. Following this, the rinse occurs in a separate system. The PERKUTE-system: economically - environmental – effektive Basic equipment Compact and sturdy construction Made of stainless steel Simple operation Space-saving 3D-blast pipe system incl. fan nozzles Low water pressure switch as dry-run protection Suction filter made of stainless steel front of the pump Automatic steam extraction Electronic basket drive 2“ ball valve for the tank emptying Safety limit switch at cover Stainless-steel pump Technical data No lieability accepted for specifications, which are subject to alteration. Tailor-made machines to be quoted on request. Before and after pictures

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

This PERKUTE cleaning system cleans simply and effectively with a very confined cleaning space. The machine is easily loaded by using either a crane or a loading carriage to place the items to be cleaned on the platform. A noticeable feature of the FR cleaning machine is that it offers several simultaneous work process. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Simple operation Space-saving Tank cover, filter basket incl. Low water pressure switch as dry-run protection Suction filter made of stainless steel in front of the pump Adapter for steam extraction Minimum operational costs because of housing insulation in sandwich construction Rotationg blast pipe system incl. fan nozzles Adjustable feed Pneumatic lift gate Programmable electronic control

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

The approved and economic system of this multi-tank-machine offers various possibilities for all applications in the area of the production and manufacturing industry. Most different process steps like cleaning, rinsing, inter-rinsing and drying makes the machine the all-round talent. The PERKUTE system: economically - environmental – effektive Basic equipment Made of stainless steel Compact and sturdy construction Simple operation Adjustable feed fork-lift facility incl. 3D-blast pipe system incl. fan nozzles Low water pressure switch as dry-run protection Electronic basket drive Tank cover in the return flow, filter basket incl. Long wash liquid service life due to the skimmer (washing tank) Programmable operation operating counter incl. Automatic steam extraction by air blower Powerful washing pump in the washing- and rinsing tank High permissible basket load 2" socket slide valve for the tank emptying Safety limit switch at cover Separate washing- and rinsing tank

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

"Closing the gap in the Toploader series" PERKUTE - Programme Extension" With the new Clean-o-mat SP 100 cleaning system, PERKUTE is extending its portfolio and is thus closing a gap in the basket diameters previously available in the successful Toploader series cleaning systems. In future, customers can choose between six different basket diameters of 450, 790, 1000, 1190, 1500 and 2000 mm and thus specify a system which matches their needs in terms of the floor footprint and the basket sizes needed. Of course, this compact and robust system has the same proven equipment features as the SP series – a low-density material separator, electronic lid control, automatic steam extraction, etc. – and turns into a real beast of burden with the permissible basket load of 500 kg in the standard version. Of course, it can also be extended with all aggregates for filtering solid matter or for separating out viscous contamination. The cleaning system can be executed as a multi-tank system...

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

FAST CUTLERY CLEANING FOR LARGE KITCHENS Our cutlery cleaning systems clean, rinse, disinfect, dry and polish your cutlery in a single operation. In just one rinsing process, all parts, from teaspoons to soup ladles, are ready for the next course - with low staff input and great efficiency. 1,250 TO 5,000 CUTLERY ITEMS PER HOUR This is how fast our systems clean your cutlery. The BRA 900 cleans 1,250 cutlery pieces per hour, the BRA 2500 up to 5,000. They are therefore suitable for enormously large quantities of dirty cutlery, and the pieces even come out of the machine dried without stains and can be used again directly. THE HDS PROCESS (HYDROMECHANICAL THREE-STAGE PROCESS) 1ST STAGE: CLEANING CUTLERY 2ND STAGE: DISINFECT AND RINSE CUTLERY 3RD STAGE: drying and polishing cutlery

Request for a quoteResults for

Cleaning systems - Import exportNumber of results

39 ProductsCategory

- Sandblasting equipment (10)

- Machine tools, metal shaping - parts and accessories (5)

- Wood veneer - machinery and equipment (3)

- Clean room systems and processes (1)

- Dishwashing machines for institutions (1)

- Internal transport systems (1)

- Metal industrial presses (1)

- Precious and semiprecious stones and pearls (1)

- Rubber - industrial machinery and equipment (1)

- Unit heaters (1)