- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- threaded inserts

Results for

Threaded inserts - Import export

NORELEM FRANCE

France

Reinforced threaded inserts allow threaded holes which have been damaged, torn out or jammed to be used again or to be repaired. This makes it possible to recover scrap and rejects of expensive products. Reinforced threaded inserts are suitable for use in various materials, including light metals and casting. Inserts with internal threads larger than M6 are supplied with four locking pins instead of two. Permissible deviations: The medium tolerance class applies to the threads listed, i.e. 6H for nut threads and 6g for bolt threads. Other dimensions ±0.25 mm. With reinforced threaded inserts we also offer a version with a stronger cross-section for use in applications with greater stress. Technical information see operating instructions for threaded inserts.

Request for a quote

NORELEM FRANCE

France

Self-tapping threaded inserts for making high-strength, wear-free, vibration resistant screw connections in materials with low shear strength such as aluminium and aluminium alloys, brass, bronze, cast iron, duro and thermoplastics. The threaded inserts are tapered at the bottom and have a cutting slot. By screwing in they cut their own threads inside a receiver hole. This guarantees a completely secure and firm anchoring in the host material. Internal thread D1 acc. to ISO 6H. The threaded inserts with cutting slot spring slightly inwards in the slot region in some materials. This results in a screw locking effect. If this is not desired, we recommend the threaded inserts with a cutting bore.

Request for a quote

SPIROL

Germany

Flexible, versatile solutions for post-mold Insert installation into thermoplastic and thermoset plastics. SPIROL's Installation Machines are the ideal foundation for stand-alone systems and enhanced assembly systems provided by SPIROL. Our standardized, time-tested, modular designs are robust, reliable and easily adjustable — allowing simple customisation to meet the specific needs of your application. More than 80% of the components in the Insert Installation Machines we design are pre-tested and production-proven standard items. This translates into faster delivery, greater reliability, and lowest cost for Insert Installation Equipment of comparable quality. We specialize in custom application-specific part holding devices. Fixturing – holding your components accurately and firmly during insertion – is a critical element to the performance of your assembly equipment.

Request for a quote

SPIROL

Germany

Moulded-In Inserts are placed over core pins by an operator or a pick-and-place robot prior to the closure of the mould cavity during the plastic injection process. Moulded-In Inserts offer exceptional torque and pull-out resistance due to unrestricted plastic flow around the Insert body, and are often the Insert of choice for thermosets and engineered plastics with a high percentage of filler. The minor thread diameter tolerance is controlled to ensure positive positioning and perpendicularity of the Insert on the core pin during the moulding process. Series 63 is symmetrical eliminating orientation and Series 65 is the same body style in a blind ended version. SPIROL's Moulded-In Inserts are made from 2024 aluminium, a light-weight, lead-free grade. SPIROL’s Series 63 and Series 65 Moulded-In Aluminium Inserts are available in thread sizes ranging from M4 (8-32) up to M8 (5/16-18).

Request for a quote

SPIROL

Germany

The course external thread of SPIROL's Self-Tapping Insert forms an internal thread within a molded or pre-drilled hole during the installation process into a plastic assembly. SPIROL Series 10 Self-Tapping Inserts are thread forming Inserts best suited for softer thermoplastics or thermosets. Self-Tapping Inserts provide the best pull-out resistance for a post-mold installed Insert, yet generally cost more than their post-mold counterparts. The external threads are designed with a thin profile to minimize induced stress in the plastic and have a relative coarse pitch to provide the maximum plastic shear surface to resist pull-out.

Request for a quote

SPIROL

Germany

Press-In Inserts are designed to be pressed into a straight hole without melting the plastic prior to installation. Ideal for use in softer plastics, the helical knurls of the Press-In Inserts are used to provide both torque and pull-out resistance and to ensure good plastic flow as the Insert rotates into the hole. Installation torque to achieve sufficient tension between the threads is not a problem in that the helical knurls are designed so that the direction of the installation torque will have the tendency to drive the Insert into the hole — which of course is not possible — as the threaded joint is tightened. A pilot only slightly smaller than the hole and of sufficient length is designed to assure straight insertion into the hole. Press-In Inserts offer rapid installation with no specialized equipment and achieve good overall joint performance. If installation equipment is required, SPIROL also offers a standard comprehensive line of Insert Installation Equipment.

Request for a quote

HONSEL-GROUP

Germany

The HONSEL COIL "cone" can be installed in the same way as a coil with tab. No additional or special tools are required for process-reliable installation. When the HONSEL COIL "cone" is screwed onto the installation spindle, the conical portion of the wire thread insert creates a clamping effect between the installation tool and the coil. This ensures a stable installation process into the work piece. Advantages: — tab-free and therefore optimally designed for e-mobility due to no risk of tab debris. — Shallower blind hole depths can be realized — Subsequent processes are no longer necessary (breaking and removing of the installation tab) — No thread skipping during installation — Cycle time reduction of 20-30 % per installation — No special tools required for the installation process — The installation process improves due to the conical portion

Request for a quote

HONSEL-GROUP

Germany

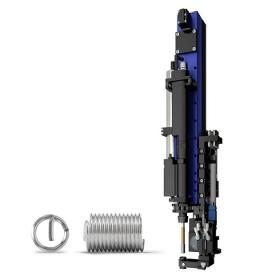

Coil screw system 2G for automated and partially automated installation of wire thread inserts. Due to the slim construction, screw systems can be placed close to each other. This leads to more efficient use of existing production areas and thus to greater economic efficiency in production. The electric linear motor is very fast at up to 3.2 m/s and enables cycle times in production to be optimized. — Screwdriver Bosch BG2 — Floating screwdriver bearings — Integrated coil transfer with rotary gripper — Linear motor — Camera

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Metric helicoidal thread inserts in stainless steel (helicoils) Reinforce the thread in low shear strength materials, such as aluminum, aluminum alloys, etc. Allow to restore a damaged thread to its initial size, ensure extremely reduced intervention time The reduced diameter of the first turn ensures that the thread insert can be placed into a hole like a regular screw For installation you may use taps and tools available in this sections: Thread insert taps, Installation tools for thread inserts Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

threaded insert manufactured by CNC turning and milling material: stainless steel male thread: 7/16-20 UNF-2A female thread: 1/4-20 UNC-2B groove milled. width 0.060 +/- 0.015 inch, depth 0.062 +/- 0.015 inch size: diameter 0.525 +/- 0.015 inch, height 0.54 +/- 0.015 inch packing: individually packed in plastic tray, carton Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

HONSEL-GROUP

Germany

High-strength for design and repair Coil threaded inserts or “coils” are an outstanding solution for achieving highstrength joints in parts made from low-strength materials (e.g. aluminium lightweight constructions). At the same time, high wear resistance is guaranteed. Furthermore, the inserts are ideally suited for the repair of damaged threads. Very simple handling Coils consist of a specially formed and coiled wire with a driver pin that can be removed after installation and can be fitted quickly and easily in just a few steps. Choose the right threaded insert for your application from over 500 sizes. Do you need a special form? No problem! Together with you, we can develop the required coil threaded insert and produce it in the highest quality.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Metric helicoidal thread inserts in stainless steel (helicoils) with screw lock Reinforce the thread in low shear strength materials, such as aluminum, aluminum alloys, etc. The self-locking thread insert is identical in construction and operating principle to the regular helical thread insert, but it also offers a braking action on the screw thanks to the particular polygonal configuration of one or more turns of the insert thread. In this way, the screw remains tightened with absolute reliability even in the presence of vibrations or shocks. The anti-unscrewing braking action remains even after numerous screwing and unscrewing operations The self-locking thread allows you to eliminate the use of other locking elements, such as elastic washers or similar, remaining effective even in the presence of high temperatures For installation you may use taps and tools available in this sections: Thread insert taps, Installation tools for thread inserts Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Helicoil finishing HSSE tap for metric thread inserts. For manual use and use in through holes Complies with DIN 81402 It is the most popular Helicoil STI tap, as in many cases it can be used without the need for roughing and bottoming taps. It also included in our Thread repair kits For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The THREAD-SERT are self-tapping inserts to be installed into cylindrical holes Suitable for installation in a wide range of thermoplastics and thermosets They are particularly designed for applications that may involve a high tensile load Very easy installation, also using a simple screwdriver Available in two versions with o without head. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. This feature is also useful in applications with electrical contacts Also known as SCREW-SERT, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The tool for fast installation of large numbers of generally used small diameter Helicoil thread inserts It is the threaded spindle, that can be used manually or with any eletric scrwedriver. We suggest the Spiralock cordless programmable screwdriver, available in our catalog The threaded spindle guides the thread insert to the established depth, limited by the special ring Attention, this tool is not suitable for mounting DIN standard thread inserts, only those with a reduced diameter Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The tool for fast installation of large numbers of generally used small diameter Helicoil thread inserts It is the threaded spindle, that can be used manually or with any eletric scrwedriver. We suggest the Spiralock cordless programmable screwdriver, available in our catalog The threaded spindle guides the thread insert to the established depth, limited by the special ring Attention, this tool is not suitable for mounting DIN standard thread inserts, only those with a reduced diameter Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The single size installation tool for UNF helicoil thread inserts designed for manual use. Can be used for installation of all types of thread inserts, including those complying with DIN 8140, used in the aeronautics and automotive, and also those with a reduced diameter for general use It is the most popular installation tool, the same contained in the Thread Repair Kits The threaded nose prepares the helicoil thread insert to the size of the thread, making installation simple and safe. It also allows installation in difficult areas, without use of the other hand to hold the insert Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The single size installation tool for UNC helicoil thread inserts designed for manual use. Can be used for installation of all types of thread inserts, including those complying with DIN 8140, used in the aeronautics and automotive, and also those with a reduced diameter for general use Specially designed for thread inserts of smaller sizes from 2-56 to 8-32 It has a threaded nose and rod so that the thread when inserted will be guided internally by the thread of the rod and externally by the thread of the nose before and a little bit after This installation tool prevents deformation of thread insert even if the operator exerts too much pressure, ensuring easy and safe installation Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The single size installation tool for UNC helicoil thread inserts designed for manual use. Can be used for installation of all types of thread inserts, including those complying with DIN 8140, used in the aeronautics and automotive, and also those with a reduced diameter for general use It is the most popular installation tool, the same contained in the Thread Repair Kits The threaded nose prepares the helicoil thread insert to the size of the thread, making installation simple and safe. It also allows installation in difficult areas, without use of the other hand to hold the insert Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The tool for fast installation of large numbers of generally used small diameter Helicoil thread inserts It is the threaded spindle, that can be used manually or with any eletric scrwedriver. We suggest the Spiralock cordless programmable screwdriver, available in our catalog The threaded spindle guides the thread insert to the established depth, limited by the special ring Attention, this tool is not suitable for mounting DIN standard thread inserts, only those with a reduced diameter Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The single size installation tool for metric helicoil thread inserts designed for manual use. Can be used for installation of all types of thread inserts, including those complying with DIN 8140, used in the aeronautics and automotive, and also those with a reduced diameter for general use Specially designed for thread inserts of smaller sizes M2 - M4 It has a threaded nose and rod so that the thread when inserted will be guided internally by the thread of the rod and externally by the thread of the nose before and a little bit after This installation tool prevents deformation of thread insert even if the operator exerts too much pressure, ensuring easy and safe installation Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Type H Helicoil HSSE tap for inch sized UNF thread inserts. Compatible with all types of helicoidal thread inserts For blind holes and manual or machine use. Spiral flutes of the tap extract chips from blind holes which allows to avoid stuffing Complies with DIN 81402 For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Helicoil finishing HSSE tap for inch sized UNF thread inserts. For manual use and use in through holes Complies with DIN 81402 It is the most popular Helicoil STI tap, as in many cases it can be used without the need for roughing and bottoming taps. It also included in our Thread repair kits For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Type H Helicoil HSSE tap for inch sized UNC thread inserts. Compatible with all types of helicoidal thread inserts For blind holes and manual or machine use. Spiral flutes of the tap extract chips from blind holes which allows to avoid stuffing Complies with DIN 81402 For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Helicoil finishing HSSE tap for inch sized UNC thread inserts. For manual use and use in through holes Complies with DIN 81402 It is the most popular Helicoil STI tap, as in many cases it can be used without the need for roughing and bottoming taps. It also included in our Thread repair kits For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The single size installation tool for metric helicoil thread inserts designed for manual use. Allows the installation of all types of thread inserts, including those complying with DIN 8140, used in the aeronautics and automotive, and also those with a reduced diameter for general use It is the most popular installation tool, the same contained in the Thread Repair Kits The threaded nose prepares the helicoil thread insert to the size of the thread, making installation simple and safe. It also allows installation in difficult areas, without use of the other hand to hold the insert Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Type H Helicoil HSSE tap for metric thread inserts. Compatible with all types of helicoidal thread inserts For blind holes and manual or machine use. Spiral flutes of the tap extract chips from blind holes which allows to avoid stuffing Complies with DIN 81402 For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Inch sized UNF helicoidal thread inserts in stainless steel (helicoils) with screw lock Reinforce the thread in low shear strength materials, such as aluminum, aluminum alloys, etc. The self-locking thread insert is identical in construction and operating principle to the regular helical thread insert, but it also offers a braking action on the screw thanks to the particular polygonal configuration of one or more turns of the insert thread. In this way, the screw remains tightened with absolute reliability even in the presence of vibrations or shocks. The anti-unscrewing braking action remains even after numerous screwing and unscrewing operations The self-locking thread allows you to eliminate the use of other locking elements, such as elastic washers or similar, remaining effective even in the presence of high temperatures For installation you may use taps and tools available in this sections: Thread insert taps, Installation tools for thread inserts Made in the EU.

Request for a quoteResults for

Threaded inserts - Import exportNumber of results

115 ProductsCountries

Company type

Category

- Tools & Hardware (60)

- Screw cutting - steels and metals (9)

- Grinding - steels and metals (7)

- ELECTRIC EQUIPMENT (5)

- Nuts and bolts (5)

- Screws (4)

- Connectors, electronic (2)

- Fastening devices (2)

- Bending - steels and metals (1)

- Caps, metal (1)

- Carpentry - machinery and equipment (1)

- Equipment and fixtures for recreational facilities (1)

- Fasteners, metal (1)

- Fittings, pipe, tube and hose - plastic (1)

- Joints, pneumatic (1)

- Measurement - Equipment & Instruments (1)

- Mechanical fixing tools (1)

- Plastic products for engineering (1)

- SMALL METAL PARTS (1)

- Sheet metal and strips, tinplate (1)