- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- surface technology

Results for

Surface technology - Import export

HOMESHOP

Poland

Ready-to-use liquid with bactericidal and fungicidal properties (in terms of yeast-like fungi), intended for disinfection of surfaces and technological lines in food industry plants, including surfaces in contact with food; for use in wellness salons, hairdressing and beauty salons, catering establishments, etc. It has a bactericidal and fungicidal effect (in terms of yeast-like fungi) in accordance with the PN-EN 13697:2002 standard. The product is not intended for use in the medical area. Biocidal marketing authorization: 5401/13.

Request for a quote

HOMESHOP

Poland

Ready-to-use liquid with bactericidal and fungicidal properties (in terms of yeast-like fungi), intended for disinfection of surfaces and technological lines in food industry plants, including surfaces in contact with food; for use in wellness salons, hairdressing and beauty salons, catering establishments, etc. It has a bactericidal and fungicidal effect (in terms of yeast-like fungi) in accordance with the PN-EN 13697:2002 standard. The product is not intended for use in the medical area. Biocidal marketing authorization: 5401/13.

Request for a quote

EC PLAZA

South Korea

We manufacture fundamental, core parts of the IT industry. Techwell now determins not only its products' quality but the industry's performance. Technology we posess is essential for the success of all IT companies and manufacturers. Building on our leading technology and R&D, Techwell is continuously improving its quality, not losing its focus on profits.

Request for a quoteWMC SINTERSTAR AG

Switzerland

Iepco AG is a Swiss production, trading and service company. For over 40 years, we have been primarily involved in the mechanical and galvanic surface treatment of metallic machine components and mould tools. In extensive research work, we have developed surface technologies that allow a special working technique. This enables us to achieve a high degree of surfaces that are suitable for production. Thanks to this economical method, production costs can be reduced enormously in a wide variety of application areas.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KME series was developed as a wet-installed centrifugal immersion pump for stationary use in tanks and basins. The direct-coupled pump with plain bearings is suitable for pumping and circulating neutral and chemically aggressive liquids in the chemical industry and process engineering, in electroplating and surface technology, in washing systems and water treatment plants, for sump drainage in industrial and municipal waste disposal plants or as a circulation pump in gas scrubbers and heat exchangers. * with various plain bearing designs * available in immersion depths from 600 - 1500 mm Features & Advantages * Compact dimensions * Abrasion resistant material combinations possible * Extremely low-vibration and low-wear operation * All wetted parts made of corrosion resistant plastic * Self-centering alignment in the bearing shell

Request for a quote

IFA TECHNOLOGY GMBH

Germany

In the textile industry, our know-how in weighing, conveying, mixing and dosing liquids and solids finds further areas of application. Areas of application include the provision of impregnates or other refinements of fibres or surfaces. IFA Technology considers your individual requirements and builds customised plants and systems for the textile industry. We supply all types of plants and systems - from standard systems to customer-specific special plants. Our innovative plants and systems for the textile industry support new developments and treatment options for fibres. Application of plants for the textile industry: Storage, mixing and dosing of liquids, for instance impregnations and additives

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

We would be happy to check the dimensional accuracy of your components in-house. LT Ultra-Precision Technology has a large number of high-precision measuring devices in precisely air-conditioned measuring laboratories for testing its own products, on which we also carry out contract measurements.The following measurement technology is available:High-precision coordinate measuring technology.Interferometric shape measurement technology for plane surfaces, spheres and aspheres.Roughness measurement technology via white light interferometer (WLI) or atomic force microscope (AFM).Reflections- and Transmissionsmessung.Ellipsometrie.Polarimetrie

Request for a quote

PFEIFFER VACUUM GMBH

Germany

Single-stage rotary vane pumps from Pfeiffer Vacuum have long been some of the most widely used products for processes in the low and medium vacuum range. Their long life and pumping speed, irrespective of the gas used, are the outstanding properties of this pump. Typical applications are found in widely ranging sectors: — Analytics (mass spectrometry, electron microscopy) — Coating technology (surface protection, decorative films, display units, monitor screens) — Vacuum metallurgy (vacuum soldering, vacuum sintering, vacuum alloys, furnace construction) — Leak detection technology (vacuum systems, automotive tanks, airbag cartridges, packaging) — Lighting industry (light bulb manufacture) — Drying industry (vacuum drying, transformer drying)

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 HME series is a design with bearingless cantilever construction that is directly coupled to the IEC Motor. Specially designed for plant engineering and confined installation conditions. It can be operated in dry installation next to the tank, thus facilitating access for maintenance and repair work. The pump is suitable for pumping /circulating neutral, corrosive and mechanically contaminated liquids. However, it can also be used in stationary installation in the chemical industry and process engineering, in surface and electroplating technology and in gas scrubbers. * temporarily also possible in dry running * directly coupled in bearingless cantilever design * available in immersion depths from 275 - 450 mm Features & Advantages * Service friendly dry running installation * Extremely low vibration and wear operation * Self-centering alignment in the bearing shell * All wetted parts made of corrosion resistant plastic

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

Schlötter Systems Dr.-Ing. Max Schlötter GmbH & Co. KG is among the leading manufacturers of electroplating systems and surface treatment facilities. With more than 1,000 systems realized since 1957, we draw upon a wealth of experience in production-ready solutions. At Schlötter, we leverage our expertise in systems engineering and surface technology to precisely tailor each system to the coating processes required by our clients. We design and manufacture rack, barrel, and manual systems, modernize facilities, and support our customers with our systems technology services throughout the long lifespan of our systems. Rack systems Barrel systems Manual systems Electroplating systems Anodizing systems Cleaning and pickling systems Chemical systems Printed circuit board systems Plastic electroplating systems Schlötter Systems in All Surface Technology Industries Schlötter systems are utilized for a wide range of surface technology applications.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

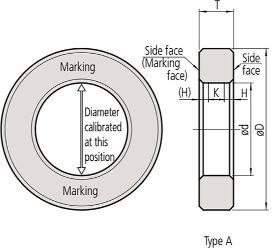

Innovacera developed a series of ceramic accessories for Inside Micrometers, Holtest and Dial Bore Gages. The ceramic material used mostly is zirconia. The zirconia ceramic setting ring advantages: High wear resistance and long service life The coefficient of thermal expansion is very small, the effect of temperature is very small The hardness is very high, there is no need to worry about surface scars. Ring gauge management is simple (regular inspection interval is long, saving cost). The Zirconia Ceramic Ring Gauges Technology: Surface Roughness: Not more than Ra0.1um Straight Angle: 0.05/φ100 Parallelism: Not more than0.015mm Each 0.5mm as one size, from 1mm to 50mm. Some Zirconia Ceramic Ring Gauges Innovacera made and size detail: 9mm, 10mm, 18mm, 20mm, 24mm, 25mm, 28mm

Request for a quote

COM2COM

Belgium

Location: Brussel Year: 2017 Surface: 0-100 m2 Theme: Technology Electro Construction Energy

Request for a quote

MARXAM PROJECT

Poland

The grinding services are a surface finishing process that includes every detail that requires the removal of machining allowance and obtaining large classes of surface roughness. For technological reasons and the number of requirements as to the further condition of the surface of the elements, we adjust the metal grinding process to individual customer requirements. Metal grinding is a finishing treatment involving the treatment of surfaces of various shapes with abrasive tools. Grinding allows you to remove burrs (deburring) and roughness, as well as machining allowance. This surface finishing method allows to obtain a surface with low roughness and desired shapes and dimensions with quite high accuracy. Surface grinding is one of the most common methods of surface treatment, for a wide variety of metals, including grinding steel, metal grinding bits, grinding welds, aluminum grinding and many others.

Request for a quoteMPT DOSING GMBH

Germany

Measurement and control In this sector, MPT represents the interests and products of WALCHEM Corporation in Holliston, Massachusetts (USA). WALCHEM is a leading manufacturer of sensor technology and controllers for the surface technology and for the water treatment technology, including pH-, redox and conductivity controllers as well as special controllers for the cooling-water and boiler water conditioning. Besides the measuring transducer, these controllers include also a control program, adapted to the respective application. Monitoring, alarming – control and telecontrol systems By default, WALCHEM’s WebMaster has available sensors and data amplifiers for various physical parameters. Using the integrated program the parameters can be linked to each other and to control parameters. Via telephone modem and Ethernet board the user is provided with information such as alarm messages and off-limit conditions worldwide. Measuring and control technology for dosing liquid media in

Request for a quote

SUPPLYIZI MATTRESS COVER PILLOW MEMORY FOAM LINEN BED

Turkey

Organic Surface Coating, which is one of the latest technologies among the surface treatment alternatives offered to the customer, ensures that all elements can be soldered well and a flat surface is obtained for proper adhesion of SMD elements to the printed circuit.

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

DLyte PRO500 are new patented Machines based on patented DryLyte technology for surface finishing of metal alloys for the industry. DLyte provides a solution to the most common industrial metals and alloys. The applications for DLyte finishing technology range from grinding, rounding and deburring to surface smoothing and high gloss polishing of high precision and aesthetic parts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STEROS GPA INNOVATIVE, S.L.

Spain

DLyte eBlast is an electropolishing equipment that offers a stream of solid-electrolyte particles propelled by a non-conductive liquid media to improve the surface quality of metal pieces. This electrochemical surface finishing process is especially designed to surface finish large or heavy parts, or with complex geometries which are difficult to polish by immersion or that require a localized finishing, like welded areas. The new electro-blasting technology is perfect for blind holes, slots, occluded areas and inner channels. This new way to apply electropolishing allows a focused surface finishing, as the media is projected towards a localized area of the piece. DLyte eBlast joins together some benefits in comparison to other surface finishing technologies. The main advantages are that this process can be applied locally in the required area. The process improves the final appearance of metal parts, with no pitting on the metal surface.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The correct air budget is an often underestimated quality factor in surface treatment technology. Where heating, cooling, movement and filtration is concerned, a great deal of energy can be saved with innovative solutions. Supply air systems replace extracted air quantities and ensure: Supply and exhaust air systems Supply air systems ensure draught-free and clean ventilation of work rooms, while high-efficiency exhaust air systems with fans and filter systems are responsible for the necessary air exhaust. This takes place with the lowest possible use of energy and with the longest possible intervals between maintenance and cleaning operations. We also offer intelligent air solutions for dryers, pre-treatment plants and cooling zones. Heat recovery A further important point is heat recovery. We can achieve up to a maximum of 80% heat recovery with the most diverse systems. Cross-current, rotary heat exchanger, heating pipe or circulatory systems – they all have their own advantages and efficiencies, which we integrate according to requirements during the planning of the plant.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The correct air budget is an often underestimated quality factor in surface treatment technology. Where heating, cooling, movement and filtration is concerned, a great deal of energy can be saved with innovative solutions. Supply air systems replace extracted air quantities and ensure: Supply and exhaust air systems Supply air systems ensure draught-free and clean ventilation of work rooms, while high-efficiency exhaust air systems with fans and filter systems are responsible for the necessary air exhaust. This takes place with the lowest possible use of energy and with the longest possible intervals between maintenance and cleaning operations. We also offer intelligent air solutions for dryers, pretreatment plants and cooling zones. Heat recovery A further important point is heat recovery. We can achieve up to a maximum of 80% heat recovery with the most diverse systems. Cross-current, rotary heat exchanger, heating pipe or circulatory systems – they all have their own advantages and efficiencies, which we integrate according to requirements during the planning of the plant.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The optimum oscillation behavior of the ultrasonic sonotrodes is determined by means of FEM (Finite Element Method) calculation. Highest precision requirements in terms of CAD/CAM calculation algorithms guarantee precise 3D contours for sonotrode manufacturing. Measuring and documentation of the amplitude distribution is performed at the vibrating sonotrode using state-of-the-art laser measurement technology. Special surface finishings result in even longer service life spans of the ultrasonic sonotrodes.

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

Thermal spraying processes (as classified in the EN 657 and ISO 14917 standards) offer a wide range of applications within modern surface technologies. Components made from a wide range of base materials can be coated with layers of high-melting-point metals or ceramics to protect them against wear and corrosion. Furthermore, thermally conductive or heat-insulating layers can be applied to highly thermally stressed components. Almost all coating materials that can be produced in powder or wire form can be processed in this way. During thermal spraying, the coating materials are fed into — and melted by — an energetic heat source (fuel gas oxygen flames from combustible gas, arcs or plasmas of noble gases such as argon, hydrogen, nitrogen, helium). The particles, which are either softened or fully molten, are accelerated in the direction of the workpiece and collide with it at high speed (40–600 m/s).

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

We create the basis for sophisticated, new and optimized products in the areas of "High-Pressure Technology" and "Engine Components" by continually expanding our expertise. In addition to complex calculations, our ongoing tasks include the assessment of suitable materials and manufacturing processes. In our state-of-the-art materials lab, we carry out results-oriented material analysis for our "High-Pressure Technology" and "Engine Components" product lines. For our "Surface Technology" product line, we check the quality of coatings via elaborate analysis and test procedures. We constantly ensure that all Nova Swiss products meet the latest requirements of the market as well as all statutory regulations. Our duties: Support for the"High-Pressure Technology" and "Engine Components" areas Analysis and testing of materials and coatings New product development Optimizations

Request for a quote

SCHOCK GROUP

Germany

We offer our customers an "all-in-one" service at the highest level: from profiles to assembly, right up to integrated system solutions. SCHOCK has extensive expertise in the assembly and manufacturing of complex assemblies. As a result, our customers can source a fully assembled assembly from SCHOCK instead of multiple individual components. They benefit from our manufacturing facilities with experienced teams in assembly, surface finishing, quality assurance, and logistics. Service Overview: Assembly of complex assemblies Joining, welding, connecting Punching, embossing, and bending technology Surface finishing Integrated functional testing Procurement of purchased parts Packaging and logistics

Request for a quote

STRIP'S D.O.O.

Slovenia

We are very flexible with our PCBA process and are able to provide you with customized solutions for your system, including supporting any special requirements when needed, such as stress-free de-panelling. Our PCBA contains all the necessary technologies such as surface mount technology (SMT), laser marking, through hole technology (THT), cleaning, coating, programming, rework and repair, to provide you custom made solution for your system.

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Oil-water-separation / degreasing bath treatment Treatment of oil-water-emulsions for surface treatment (e.g. pre-treatment of metal parts for ed-paint), recovery companies (e.g. for the treatment of alkaline emulsions for part washing), and so on. Separation of emulgated oil particles and recycling of the cleaned liquid into the degreasing bath Concentration of oil-water-emulsions for disposal Cleaning of the oil-water-mixture for indirect lead-in Principle of this process: Aqueous degreasing baths content a tenside combination, alkalines like soda, caustic soda, phosphate, silicate and further complex molecules. The degreasing bath is loosing its efficiency, when to oil content reaches some g / litre. External pollutions also degrease the degreasing efficiency. By ultrafiltration, the oil content can be separated from the degreasing bath and the oil will be collected in the concentrate. The degreasing bath will be dumped into a buffer tank and then pumped in the working tank of the

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Recovery of acids and acidic rinse waters Additionally to the pickling bath treatment by microfiltration and ultrafiltration, the recovery of acid becomes more and more important. Additionally to sulphuric and hydrochloric acid, also mixed acids (HF / HNO3) can be recovered. The first step of the acid recovery is mostly a sludge separation by microfiltration. Downstream, diffusion dialysis, electrodialysis or nanofiltration is used for metal separation. For the treatment of rinse waters, OSMO Membrane Systems GmbH offers reverse osmosis or electrodialysis plants.

Request for a quote

BSI CLEANING

Luxembourg

- Wide process from 6 cm to 50 cm - Uniform plasma curtain - 3D treatment - Very low treatment temperature - Work with nitrogen - Manageable and easy to use - Easy to integrate

Request for a quote

BSI CLEANING

Luxembourg

- Powerful and focused treatment - Used in the open air - Quick and cold - Works with compressed air - Manageable and easy to use - Compact generator and tube - Simple to integrate

Request for a quoteResults for

Surface technology - Import exportNumber of results

45 ProductsCountries

Company type

Category

- Electrical & Electronic Components (5)

- Painting and varnishing of rubber and plastic (2)

- Pumps (2)

- Aquaculture and pisciculture (1)

- Ceramics, industrial (1)

- Chemicals - Basic Products & Derivatives (1)

- Cutting - steels and metals (1)

- Goods handling systems, continuous (1)

- Grinding - steels and metals (1)

- Laser - cutting and welding machines (1)

- Marking - diverse products (1)

- Metallurgy - machinery and installations (1)

- Outsourcing - product development (1)

- Polishing - machine tools (1)

- Precision measuring instruments (1)

- Pressure regulators (1)

- Rails and sliding frames (1)

- Screen printing on metal (1)

- Shaping - steels and metals (1)

- Shaving brushes and accessories (1)