- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machinery and equipment

Results for

Machinery and equipment - Import export

PACKFEEDER

Spain

The in-Line series from Packfeeder has a wide range of systems and models of machines for unscrambling bottles of different dimensions, characteristics and materials, with speeds that can be adapted to the different production needs. The in-Line Packfeeder bottle sorter system can work efficiently with packages of very different volumes, from small dimensions of 3-4ml to large packages of more than 1L, at a wide range of speeds that can reach 500 u/min. The STD range of the in-Line series is comprised of different sized feeders that adapt to the different volume needs of packages and production speeds. They all provide extraordinary versatility, which allows for them to work with countless products, as they can be configured according to the needs of a wide range of industrial sectors.

Request for a quote

FORMEX MAQUINARIA

Spain

CLEANLY DOSES AND INJECTS FOOD MASSES OF DIFFERENT DENSITIES AND CHARACTERISTICS: viscous, liquid, soft, creamy, dense, sugary, etc. THE MIXTURE CAN HAVE SOLID PARTICLES INCORPORATED. For small and medium productions, although they can also be integrated into a working line or conveyor to achieve a higher degree of automation. IDEAL FOR DISPENSING PRODUCTS SUCH AS: muffins, plum-cakes, tartlets, custards, jams, sauces, fruit fillings, delicate fillings such as mousse, salad dressings, soups, Russian salad, creams with cereals, dairy products, etc. A WIDE RANGE OF ACCESSORIES AND DOSING OUTPUTS provide versatility when working with different products efficiently: mould conveyor, hose and hand gun, transfer pump, rotary cutting gun, injector nozzles, elevator, etc., elements that will make your work more precise.

Request for a quote

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

Machined parts or 3D additive manufacturing. Adaptable to production lines in the perfumery and cosmetics sector, packaging lines, dispensers and filling. We have a variety of materials and colors, we work with antistatic materials suitable for the sector, we have extensive experience in packaging, as well as special parts for your bottling machinery, maintenance solutions, stands for trade shows, spare parts, etc.

Request for a quote

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

At Induplast we work with plastics for the food industry that have been approved by FDA regulations for contact with food products and we have engineering plastics with additives for metal detection that prevent contamination and guarantee traceability and compliance with migration limits. We also use high-performance machinery that allows us to obtain plastic moulds for food and food machinery, guaranteeing the best quality.

Request for a quote

RAYPA

Spain

Our Kjeldahl digesters represent a compact block digestion system, standing out for its efficiency, versatility, and scalability to perform safe Kjeldahl digestions. This internationally recognized reference method is used to analyze nitrogen and protein content in various fields of application. Moreover, these digesters are utilized for sample pretreatment (hydrolysis) for subsequent fat extraction and soil digestion for metal analysis. The new generation of MBC Series digesters has enhanced its process control thanks to a 5-inch color touch screen and Wi-Fi connection for result analysis in RAYPAnet. The new microprocessor allows for advanced programming of cycles and the timer, offering up to 10 customizable program names according to the application note, and configurable with up to 10 temperature segments. To adapt to the specific needs of each laboratory, we offer a wide range of models of our Kjeldahl digesters. Contact us now or visit our website for more information.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PACKFEEDER

Spain

This robotic unscrambler, configurable with one, two, three or even four robots, offers a wide range of applications and possibilities. Our combination of delta robots with an intelligent track system makes the pickFeeder the most versatile automatic format change machine of the market, optimizing the performance of the intelligent systems and guaranteeing the best soft transfer in the world. Thanks to the artificial vision, picking and tracking systems developed, the equipment will adapt automatically to the changing requirements in terms of shape, colours and needs of the packaging lines. With the pickFeeder series, we propose an automatic changeover to reduce the amount of downtime between production runs and forget about any kind of adjustment, setting or test before starting to produce again. This also has a positive effect in terms of reducing the total cost of the equipment in its entire life cycle.

Request for a quote

PACKFEEDER

Spain

This module adapts the Packfeeder feeder to a packaging line that uses pucks to transport products. The main benefits of the Packfeeder puck system are: - Easy-to-operate and efficient design. - Little additional space is required, ensuring that the puck feeder assembly stays extremely compact. - Outstanding ergonomics during use and maintenance thanks to the in-line modularity concept. - It is the simplest puck loading system on the market. - Works with both closed and open pucks in any shape and size. - Guarantees that 100% of the pucks are full after passing through the feeder with no additional sensors needed. - System adaptable to existing puck production lines.

Request for a quote

PACKFEEDER

Spain

Either due to the container having handles, serigraphs or simply geometries that make it asymmetrical, the Packfeeder modules provide fast and effective solution to the feeding requirements. The main benefits of the Packfeeder orientation system are: - Simple and efficient operation. - Little additional space required, keeping the feeding and unscrambling of packages unit very compact. - Great ergonomics in its use and maintenance thanks to the modularity in line concept. - Ability to feed packages on a belt or inserted into pucks. - Proven effectiveness in any asymmetric geometry that requires feeding.

Request for a quote

STE TECPHARM

Spain

The Granulation Line integrates into a single frame and control panel all options for solid forms production process: ■ Mixing and Granulation: High Shear Granulator. ■ Drying: Fluidized Bed Dryer. ■ Calibration: Conical and Cylindrical Calibrators. It minimizes the space requested in clean-room, reduces the risks of cross-contamination, and gives maximum versatility to process development and scalability studies.

Request for a quote

STE TECPHARM

Spain

The OPTIMA TABLET COATER is a perforated coating pan designed for the film coating of tablets or pellets, suitable in aqueous and organic coatings, for the pharmaceutical industry. PATENTED COATING TECHNOLOGY THAT INCREASES THE BATCH SIZE RANGE FROM 10% TO 100% AND OPTIMIZES THE PARAMETER ADJUSTMENT FULLY AUTOMATICALLY. Its high technology allows an automatic adjustment control of the flow, avoiding the damp, saving coating and optimizing the processing time. Innovative high-quality equipment certified by accredited entities. Fully designed and built in Europe following regulatory requirements and GMP´s normative. The OPTIMA TABLET COATER controls each critical variable which is decisive for the dynamic equilibrium, such as: ■ Applied liquid flow. ■ Inlet airflow. ■ Exhaust airflow. ■ Inlet and exit air temperature. ■ Tablet temperature during the process. ■ Turning the speed of the pan drum.

Request for a quote

STE TECPHARM

Spain

The High Shear Mixer Granulator is designed to optimize the wet granulation process. Used to turn a fine-powder heterogeneous mixture into a uniform granulation, with increased particle size and higher density, offering proper flow and compactness properties, in a short time process and with repeatability. Innovative high-quality equipment certified by accredited entities. Fully designed and built in Europe following regulatory requirements and the GMP´s normative. MAIN FEATURES ■ Standard equipment with capacities ranging from 25 L to 1.400 L. [Other dimensions on request]. ■ In-wall design to be integrated into the cleanroom. ■ Manufactured in AISI 316L. ■ Mirror polished Ra < 0,5. ■ No contact top cover without supports in the container. ■ Bottom impeller and side chopper to guarantee the intensive mixing in a very short time period. ■ Control of endpoint by time or by Torque. ■ PLC + HMI for the control in manual and automatic mode, with recipe editing.

Request for a quote

STE TECPHARM

Spain

Fluidized Bed Dryer designed for 3 different processes: ■ Drying of wet granulate (dryer). ■ Top drive granulation (granulator). ■ Bottom spray coating (coater). Innovative high-quality equipment certified by accredited entities. Fully designed and built in Europe following regulatory requirements and GMP´s normative. STE TECPHARM offers all range of services: installation “turnkey concept” in the client facilities, start-up, qualification, training, and production support. MAIN FEATURES ■ From 30 L to 1.540 L. [Other dimensions on request]. ■ In-wall design concept. ■ Built-in AISI 316L, mirror polished Ra < 0,5. ■ PCL + HMI in manual and automatic mode, with recipe editing. ■ 12 bar pressure-shock resistance.

Request for a quote

SAPLI SOLUTIONS

Spain

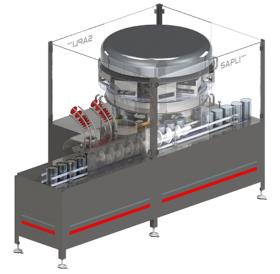

Continuous or Intermittent motion highly Accurate Rotary Powder Filler is a suitable solution for a wide range of powdered and granule products to be filled with medium and high production rates. One or more filling stations options, depending on product flow characteristics and a packaging formats. Rotary machines are available with over turrets of 12 to 48 pockets, with outputs up to 400 containers per minute. These can be integrated with gross or tare and gross check-weigher feed-back systems.

Request for a quote

SAPLI SOLUTIONS

Spain

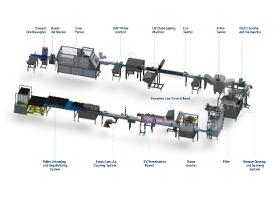

Stand-alone machinery and key turn projects for fully-automatic multiformat filling and packaging lines. Machinery for powdered and solid products, such as Powdered Milk, Infant Formula, Sport Supplements, Coffee, Snacks, Confectionery Products and others in metal tin cans, plastic containers, glass jars and carboard tins.

Request for a quote

SAPLI SOLUTIONS

Spain

• Vacuumgassing seamers from Sapli are high performance solution for low and high production speeds. • The modular principle allows adding new seaming stations in the future, in case of increasing of production capacities. • Suitable for the seaming and vacuum gassing products in tinplate, aluminium, paperboard and plastic cans packaging across a wide range of industrial sectors. • Perfect sealing technology with adjustable working speeds. • Easy and intuitive format change. • Adjustable levels of residual O2 level after seaming, depending on the product requirements for guaranteeing a long shelf-life of the product. • Vacuum and gassing pressures are configurable, and can be monitored on each can seaming cycle • Guarantying the highest food security and produced with EU Declaration of Conformity. • Suitable for the wide range of tin cans formats, heights and diameters. • Multiformat principle allows working with lots of packaging formats at the same machine.

Request for a quoteResults for

Machinery and equipment - Import exportNumber of results

16 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (5)

- Pharmaceutical industry - machinery and equipment (4)

- Bottling and filling - machinery and equipment (3)

- Food industry - machinery and equipment (3)

- Pastry-making - machinery and equipment (1)

- Food canning and preserving - machinery and equipment (1)

- Cosmetics industry - machinery and equipment (1)