- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rolling bearings

Results for

Rolling bearings - Import export

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on our many years of experience in developing and manufacturing high-quality machine components, GMN has specialized in the area of high-precision ball bearings as well as the production of high-performance and long-lived deep groove and spindle ball bearings to meet – or even exceed – the highest precision classes P4 and ABEC 7. Certification under international standards ensures the highest precision in the development and manufacturing of GMN ball bearings and guarantees constant, outstanding qualities related to speed suitability, stability and longevity. The broad product range includes a large selection of standard solutions as well as requirements-tailored special designs.

Request for a quote

VILLINA LLC

Russia

We supply thrust bearings (bearing plates, end thrust bearing), rolling bearing (combined type) and support bearings (plain journal bearings) made of the following material: tungsten carbide (WC); silicon carbide (SiC), VK8 alloy, etc.

Request for a quote

ROBINSON CO.

Turkey

It is used for breaking and crushing wheat in flour factories. The most important machine of the flour mill, the roller mill consists of two pairs of roller balls operating in parallel. Unlike the pneumatic roller, the incoming product amount is measured with the help of a sensor or load cell. Feeding rollers change speed according to the incoming product amount and provide homogeneous flow. At the same time, the gap between the rolls is closed by pneumatic pistons and allows the product to be grinded by passing through the rolls. The bearings of the rolls are ductile iron and the arms of the rolls are conical. It is produced with gear drive and belt drive. It can also be produced with an optional touch control screen. Especially thanks to the side covers that can be opened one by one based on the opening system, it provides fast and easy access and the possibility of rapid ball removal with the cover opened on the ball.

Request for a quote

IGUS® GMBH

Germany

drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration

Request for a quote

NORELEM FRANCE

France

Housing washer, shaft washer and rolling elements, bearing steel. Cage, steel. Note Axial ball bearings accept high axial loads from one direction but may not be loaded radially. The bearings are separable. This means the bearing parts can be fitted independently of each other. The main dimensions of the axial ball bearing conform to ISO 104 and DIN 711. Dimensional and running tolerances correspond to tolerance class PN acc. to DIN 620. These tolerance classes are standard and are well suited for most applications.

Request for a quote

NORELEM FRANCE

France

Steel housing. Nitrile rubber seal. Preloaded highaccuracy bearings with a 60° thrust angle. The bearings accept both radial and axial forces from both directions. Due to their preload, the angular contact ball bearings provide a high level of stiffness, excellent concentricity, precise tool positioning and repeatability. The integrated lowfriction seal effectively keeps dirt away from the bearing, thereby ensuring excellent operating safety and a long service life. The bearing friction coefficient Mrl is a reference value. The moment of inertia corresponds to that of the rotating inner ring. The limiting speeds are applicable after grease is applied. Technical data All bearings are supplied ready for mounting with lubricating grease type KE2P35 acc. to DIN 51825. Housing and shaft tolerances correspond to roundness tolerance class IT2 and perpendicularity tolerance class IT4.

Request for a quote

NORELEM FRANCE

France

Ceramic bearings Si3N4. Bearing cage PTFE. For most applications Si3N4 is the preferred material for ceramic bearings. Silicon nitride bearings are light, very hard and highly wear resistant. High and ultrahigh performance bearings are used in e.g. aerospace technology, metal production industries (high application temperatures), machine manufacturing, chemical industries (chemically aggresive substances), pharmaceutical and medical industries, semiconductor and biotechnology (clean room enviroments which may not be contaminated by lubricants). On request Special version with PEEK ball cage. Without ball cage.

Request for a quote

NORELEM FRANCE

France

Inner ring, outer ring and rolling elements, bearing steel. Cage sheet steel. Labyrinth seal sheet steel. Lip seal NBR. Version 2Z = sealed both sides with noncontact labyrinth seals. 2RSR = sealed both sides with contact lip seals. Note Deep groove ball bearings accept high radial and axial loads. Axial loads are absorbed in both directions. The versions 2Z and 2RSR are lubricated for life with a high quality grease. The main dimensions of the deep groove ball bearings conform to DIN 6251. Dimensional and running tolerances correspond to tolerance class PN acc. to DIN 620. The radial internal clearance corresponds to the clearance CN acc. to DIN 6204. These tolerance classes are standard and well suited for most applications.

Request for a quote

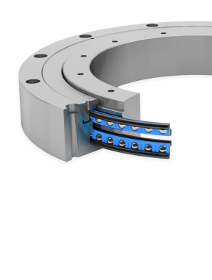

FRANKE GMBH

Germany

Franke bearing asseblies type LVC are bearing assemblies made of steel, designed as double row angular contact ball bearings with integrated bearing elements. Franke LVC are suitable for highest circumferential speeds. They convince by very high dynamics and a very low rotational resistance. The double row angular contact ball bearings in a 4-point arrangement are preloaded. They are insensitive to shocks and vibrations. The low rotational resistance and the minimal breakaway torque reduce the required drive power. Due to the low coefficients of friction, Type LVC bearing assemblies operate almost maintenance-free and achieve a long service life.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Special grease for the long-term lubrication of ball and plain bearings where electrical charge is possible, e.g. in electric engines, foil- stretching and foil-printing machines, etc. Advantages and benefits Long-term lubrication grease with a wide temperature range and good corrosion protection The special lubricating concept makes sure that electrostatic charges in roller bearing applications are destaticized through the grease, so that local discharges are avoided Proven especially for the lubrication of roller bearings below 1 ampere

Request for a quote

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing | Maintenance-free | Steel / graphite bronze | With embedded solid lubricants GAP-MET®/S is a maintenance-free composite plain bearing. However, oil or grease lubrication is possible. High load capacity and strength, for all slow movement types, suitable for contaminated environments, no moisture absorption, good chemical resistance. For technical details, please visit the product page on our website!

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Low temperature grease with solid lubricants Description Castrol Molub-Alloy 243 Arctic grease is intended for use in plain and rolling bearings operating at temperatures down to -55°C. It is designed to meet the performance requirements of the MIL-G-10924C specification. For effective lubrication at very low temperatures, the most important requirement is that the grease remains soft, especially in rolling bearings. Stiff lubricating grease in rolling bearings prevents the rolling movement when starting or even causes the rolling elements to slide during operation, which may destroy the bearings. Corrosion protection is equally important for low-temperature greases. Due to the temperature fluctuations from higher operating temperatures during the day to low temperatures during the night, the air humidity is reflected on the cold metal surfaces . Under these circumstances, the risk of corrosion is particularly high.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of friction and rolling bearings at low operating temperatures Grease lubrication of friction and rolling bearings at high speeds Grease lubrication of bearings with low coasting moments or low bearing play Advantages and benefits NSF H1 registered Low-viscosity, fully synthetic base oil ensures the functionality of the lubricating film up to -70°C Very good conveying capability in central lubricating systems also at low temperatures Clean the surfaces for optimal effect. Before filling for first time, remove anti-corrosion agent. Fill the bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of friction and rolling bearings of all kinds at all permissible speeds and subject to high pressure loads, in particular of heavily loaded rolling and taper roller bearings, e.g. on rolling stands, hot and cold shearing systems, sliding blocks and spindles Advantages and benefits Excellently suited for long-term lubrication of grease lubricating points subject to heavy loading Highly effective due to outstanding EP additives and high resistance to water

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of open toothing, friction and rolling bearings, threaded spindles, hinges, guides on windlasses, ship´s cranes, underwater devices, offshore components or in wet areas of the textile industry Corrosion protection of moving parts subject to seawater in coastal and marine areas or constant influence of water Advantages and benefits Excellently suited as a waterproof special grease above and under water Highly effective due to optimum wear and outstanding corrosion protection Economical due to combined protective effect Lubrication of open toothing, friction and rolling bearings, threaded spindles, hinges, guides on windlasses, ship´s cranes, underwater devices, offshore components or in wet areas of the textile industry Corrosion protection of moving parts subject to seawater in coastal and marine areas or constant influence of water Advantages and benefits Excellently suited as a waterproof special grease above and under water

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of plain and rolling bearings in high-temperature range, where a mineral oil based grease cannot be used, e.g. on hot-air blowers and fans, autoclaves, drying ovens or systems in steelworks and foundries Advantages and benefits Drip-free hot bearing grease for a broad temperature range with high oxidations stability and moisture resistance Excellently suited for long-term lubrication of grease lubricating points subject to high-temperature loading Highly effective due to optimum high-performance formula Broad range of uses outside normal grease performance areas

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of rolling bearings at operating temperatures of -50°C to +180°C For long-term lubrication of temperature-stressed electric motor bearings, e.g. in household appliances or of bearings which are to start up easily at low temperatures Initial lubrication of roller bearings, such as ball bearings that are open, closed on one side, or sealed off on both sides Advantages and benefits Broad range of uses outside normal grease performance areas Reduces wear and friction High resistance to oxidation Wide operating temperature range and good low-temperature properties Very good corrosion protection Very good compatibility with most plastics and elastomers

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of plain and rolling bearings at high temperatures and high loads, e.g. on hot-air fans, converters, pouring ladles, sintering systems, conveyor systems subject to heat etc. Advantages and benefits Excellently suited for reducing friction and wear, protection against corrosion and impurities Maintenance of lubricating effect even at high temperatures and loads Highly effective due to selected combination of active ingredients for good corrosion protection properties, good resistance to ageing and excellent EP properties

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of normal-load friction, rolling and pivoting bearings Lubrication of spindles and guides at machines Lubrication of moving parts at fine-mechanical devices as well as household appliances Advantages and benefits Lubrication when dark-coloured lubricants cannot be used Saving of maintenance and lubricant costs by reducing downtimes and corrective maintenance Waterproof NSF H2 registered Also available as spray version OKS 471 (without NSF certification)

Request for a quote

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547 TEF-MET/B is a versatile, corrosion-resistant dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547 TEF-MET is a versatile dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! For technical details, please visit the product page on our website!

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Extreme-temperature grease on the basis of perfluorinated polyether oils (PFPE) for use in food processing technology at maximum loads and temperatures. Grease lubrication of friction and rolling bearings in the high-temperature range Application, for example at tunnel kiln cars, baking, burn-in and drying furnaces, hot gas units, reaction vessels, boiler plants, roller and conveyor rollers in continuous furnaces, etc. Use at bearing points under influence of chemicals/fuel Advantages and benefits Maximum water and steam resistance Extraordinary resistance to chemicals, for example to solvents, for example benzene, benzol, acetone, trichloroethylene and against inorganic acids, such as sulphuric acid, hydrochloric acid and nitric acid as well as stearic acids, alcohols and halogens Excellent plastic and elastomer compatibility For long-term lubrication of lubrication points subjected to high pressure up to 300°C

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For lubricating machine elements under high loads (also under water influence) Lubrication of chains, joints and guides Lubrication of rolling and friction bearings Lubrication of toothed gearings, fittings, hinges and locks Advantages and benefits NSF H1 registered MOSH/MOAH-free The optimal additives allow good resistance to oxidation and ageing for long operating and durability Resistant to cold and hot water, steam and alkaline and acidic disinfectants and cleaning agents

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Gearbox lubrication of heavily loaded, relatively slow-running toothed gearing when grease is used instead of oil due to leaks For heavily loaded and impact-loaded drives Chain lubrication, e.g. of hollow-pin chains in the conveyance and transport sector, for exposure to water and steam and at higher operating temperatures Bearing lubrication of friction and rolling bearings in annealing yards and drying systems, manipulators and robots, cooling-bed and conveyor systems, machines in food packing industry, steam sterilisers etc. Advantages and benefits Excellently suited for corrosive operating conditions with high operating temperatures and high pressure and impact loads Economical due to optimised formula Enables wear reduction, decreasing failure times and enabling long-term lubrication Long-acting, highly adhesive, temperature-stable and waterproof, noise-damping, impact and pressure resistant

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of plain and rolling bearings at high temperatures, e.g. in painting and drying ovens, converters, pouring ladles, heating systems, hot-air fans, charging cranes, vulcanising systems and electric motors Advantages and benefits Excellently suited for long-term lubrication of grease lubricating points subject to high-temperature loading Highly effective due to optimum solid lubricant formula Broad range of uses above normal grease performance areas Reduced maintenance and lubricant costs due to possible safety lubrication Drip-free hot bearing grease for long-term and safety lubrication in a broad temperature range For best results clean the lubricating point carefully. Clean with solvents like OKS 2610/OKS 2611 Universal Cleaner. Remove the corrosion protection ahead of the initial filling. Fill the bearings in a way that all the functional surfaces for sure get the grease.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Longtime Blanc. Molub-Alloy Blanc (05/20/2021) White multi-purpose grease for high bearing pressures and long-term lubrication Description Castrol Molub-Alloy Blanc (previous product name Castrol Longtime Blanc) is a white multi-purpose grease for use at high bearing pressures and long-term lubrication. It is characterized by its special adhesive properties and its water-resistant, sealing properties. Application Molub-Alloy Blanc is used in the food and beverage industry, especially in wet operations, in dusty environments and in conveyor lines, canning and bottle filling systems and labeling machines, where there is no contact between the lubricant and the food or beverage . Molub-Alloy Blanc can be used for long-term lubrication under high pressure loads, vibrations, shock loads, in highly loaded joints, plain and rolling bearings and pipe tracks.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Longtime Blanc. Molub-Alloy Blanc White multi-purpose grease for high bearing pressures and long-term lubrication Description Castrol Molub-Alloy Blanc (previous product name Castrol Longtime Blanc) is a white multi-purpose grease for use at high bearing pressures and for long-term lubrication. It is characterized by its special adhesive properties and its water-resistant, sealing behavior. Application Molub-Alloy Blanc is used in the food and beverage industry, especially in wet operations, in dusty environments and in conveyor lines, canning and bottle filling systems and labeling machines, where there is no contact between the lubricant and the food or beverage . Molub-Alloy Blanc can be used for long-term lubrication under high pressure loads, vibrations, shock loads, in highly loaded joints, plain and rolling bearings and pipe tracks.

Request for a quoteResults for

Rolling bearings - Import exportNumber of results

137 ProductsCountries

Category

- Silicones (38)

- Bearings, antifriction (29)

- Bearings, ball (28)

- Plain bearings (28)

- Lubricants, industrial (14)

- Manicure instruments (11)

- Bearings - ball, needle and roller (9)

- Heat pumps, industrial (9)

- Bearings, roller (5)

- Pedicure instruments (4)

- Measurement - Equipment & Instruments (3)

- Sealing and wrapping - machinery and equipment (3)

- Bearings, needle (2)

- Bronze (2)

- Joints, pneumatic (2)

- Cold rolled steel strips (1)

- Flour milling - machinery and equipment (1)

- Flour-milling (1)

- Greases, crude (1)

- Handling trolleys (1)