- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- positioning table

Results for

Positioning table - Import export

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Nano Linear NT is a linear motor drive high thrust pick & place unit with compact integral X and Zaxes, using IKO CLube Linear Way ML in the table guiding parts. Thanks to the adoption of a system which drives the moving table with a link mechanism, it realizes both higher thrust of the linear motor and weight reduction of the moving parts and reduces tact time. By entering a positioning program, you may set flexible operation patterns and change strokes easily according to the workpiece. IKO Nano Linear NT is an optimal compact positioning mechanism for semiconductor and LCD manufacturing machines, as well as testing and inspection equipment and electronic parts assembling machines which require a clean environment.

Request for a quote

AVM AUTOMATION

France

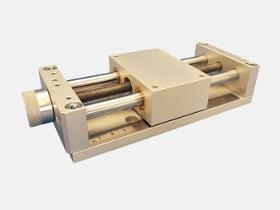

Manual positioning table drived by metric fine thread screw (pitch 1 - 1,25 mm). Actuated by grip knob. Guided by 2 rods on bronze bearings. Robust and economical table. Interchangeable with the 309B range. Options : Positioning indicator Position clamping Base plate (with or without ruler) Assembly in XY or YZ table

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

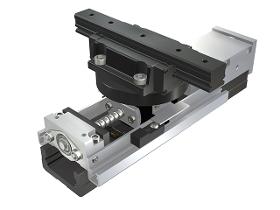

Precision Positioning Table LH is a highreliability, highprecision and highrigidity positioning table made of a cast iron slide table and bed with high rigidity and excellent vibration damping performance, incorporating an IKO Linear Way and using a precision ball screw for the feeding mechanism. By incorporating two Linear Ways in parallel, it achieves stable running accuracy, high positioning accuracy and large carrying mass. It is available in four sizes ranging from 120 mm to superlarge 420 mm in table width, and tables combining these in a twoaxis specification have also been serialized. It is optimum as a highprecision positioning mechanism for usage where the applied load is large and the stroke length relatively long.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Precision Positioning Table LH is a highreliability, highprecision and highrigidity positioning table made of a cast iron slide table and bed with high rigidity and excellent vibration damping performance, incorporating an IKO Linear Way and using a precision ball screw for the feeding mechanism. By incorporating two Linear Ways in parallel, it achieves stable running accuracy, high positioning accuracy and large carrying mass. It is available in four sizes ranging from 120 mm to superlarge 420 mm in table width, and tables combining these in a twoaxis specification have also been serialized. It is optimum as a highprecision positioning mechanism for usage where the applied load is large and the stroke length relatively long.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

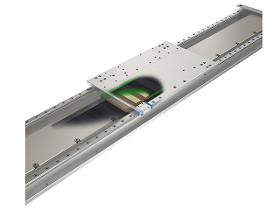

Precision Positioning Table LB is a highspeed movementenabled, long stroke positioning table that adopts a highly durable and hightensile timing belt containing steel cord incorporated into the feeding mechanism of the slide table, and uses a high torque 5phase stepper motor as the driving motor. The slide table and bed are made of lightweight highstrength aluminum alloy. Two sets of IKO Linear Way are incorporated into the linear motion rolling guide in parallel, realizing stable and high running performance. Precision Positioning Table LB is ideal as a positioning mechanism, for assemblers, conveying machines or pallet changers that work at high speed.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Super Precision Positioning Table TX is a positioning table with extremely high accuracy which is created based on the high precision, high rigidity and well proven IKOPrecision Positioning Table LH by using cylindrical rollers for rolling elements and incorporating IKOLinear Roller Way Super X, which has bestinclass running performance as a linear motion rolling guide, with fullyclosed loop control. Optimal for highly accurate positioning where the existing rolling guides could not be used.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Precision Positioning Table L is a lightweight, long stroke positioning table configured with the slide table and bed made from highstrength aluminum alloy. High accuracy and carrying mass are realized by incorporating two sets of IKO Linear Ways in parallel, and using a precision ball screw in the feeding mechanism. Maintenance work such as relubricating with grease can be reduced significantly by CLube. Various table sizes and stroke lengths are available, and dedicated XY brackets are also serialized, enabling systems such as orthogonal robots to be easily configured according to the application. Precision Positioning Table L is ideal as a highprecision positioning mechanism, for assemblers, processing machines, or measuring instruments.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Precision Positioning Table TS/CT is a compact positioning table made of a cast iron slide table and bed with high rigidity and vibration damping performance, incorporating an IKO Crossed Roller Way with a solid record in the field of precision linear motion rolling guides, and using a precision ball screw for the feeding mechanism. IKO Precision Positioning Table TS/CT is available in oneaxis and twoaxis specifications and is widely used in precision measuring instruments and precision assemblers that require high precision positioning.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Micro Precision Positioning Table TM is an extremely compact precision positioning table incorporating a precision grinding ball screw with a thread diameter of 2 mm and an IKO Micro Linear Way L with a track rail width of 2 mm, wellestablished in the field of ultrasmall equipment.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

TU Series is a compact and slim type positioning table, consisting of a Ushaped track rail and a slide table. The slide table assembled inside the Ushaped track rail is an integral part of a linear motion rolling guide mechanism, in which two rows of large diameter steel balls are arranged in four point contact with raceways. Owing to this design, stable high accuracy and high rigidity are obtained in operations even under fluctuating load varying in direction and magnitude and complex load. Also, by adopting a Ushaped track rail, the rigidity of track rail under moment load and torsion is greatly improved. TU Series includes six sizes with a track rail width of 25 mm to 130 mm. For each of them, slide table length can be selected. Also, ball screw types and leads, motor types, and sensor installations, etc. can be selected to obtain an optimum positioning table suitable for each application.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Cleanroom Precision Positioning Table TC···E is optimal for use in high cleanliness environments for semiconductor and LCD manufacturing machines. The unique highairtight structure seals the driving part and guiding parts of the slide table, and prevents dust generation around the table. IKO Cleanroom Precision Positioning Table TC···E achieves cleanliness class 3 by enhancing the airtightness inside the table.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Precision Positioning Table TE is a lightweight and compact positioning table using highstrength aluminum alloy for its main components, with a slide table assembled inside a Ushaped bed. A precision ball screw is used for the feeding mechanism, enabling highreliability and highprecision positioning. Lubrication part CLube is built into the linear motion rolling guide and ball screw, achieving long term maintenance free performance and reducing lubrication work. Various specifications such as ball screw lead, motor type and sensor mounting can be configured, enabling the optimum positioning table to be configured according to the application. Ideal for a wide range of applications ranging from equipment that requires high positioning accuracy such as parts machining, assembly, inspection and conveying equipment through general conveying fields.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

The IKO Alignment Module AM is a positioning module developed for alignment stages by combining high rigidity Crossed Roller Bearings and Linear Way E with Precision Positioning Table TU. Alignment stages can be configured without adjusting the height of each alignment module, since the height tolerance is managed with high accuracy of ±10 μm.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Alignment Table AT is a rotary positioning mechanism capable of precise angle correction, in which a high rigidity steel table and bed are used and IKO Crossed Roller Bearings are incorporated in the bearings supporting the table. Alignment Table AT uses the ball screw drive to convert linear motion into circular motion in a fixed angle range and positions the table in the rotational direction. An IKO Linear Way L is used for the linear motion rolling guide of the ball screw drive mechanism, combined with a precision ball screw to achieve high precision positioning. Placing Alignment Table AT on the slide table of the IKO Precision Positioning Table enables the configuration of a low height XYθ multiaxis positioning mechanism. This enables the table to be used as an alignment table for precision measuring equipment, inspection equipment and assemblers.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

The IKO Linear Motor Table LT is a compact and highprecision positioning table made of aluminum alloy, with an optical linear encoder built in and an AC linear servomotor incorporated between moving table and bed. Three series (Compact Series LT···CE, Long Stroke Series LT···LD and High Thrust Series LT···H) are available and can be selected according to the application. The lightweight moving table and large thrust force of Linear Motor Table LT enables operation with high acceleration/deceleration and high response. Further, the advanced servo technology achieves high static stability and speed stability. Linear Motor Table LT is ideal for applications such as semiconductors and liquid crystal related equipment, measuring instruments, assemblers and conveying machines that require highspeed work.

Request for a quote

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Grid spacing 50 ±0.02 mm. Tombstones with grid holes are used on horizontal machining centres. The alphanumerically labelled grid holes guarantee a defined assignment of clamping elements by repeat setups. The tombstones conform to machine tables for machine tools acc. to DIN 55201 and JIS 6337-1980. Please order locating pins for positioning subplates on machine tables acc. to DIN 55201 separately. Please order protection plugs to plug unused grid holes separately. Ring bolts for hoisting are supplied. Other dimensions available on request. Drawing reference: 1) grid hole 2) hole for DIN 912 cap screw (D3/D4)

Request for a quote

NORELEM FRANCE

France

Grid spacing 50 ±0.02 mm. Tombstones with grid holes are used on horizontal machining centres. The alphanumerically labelled grid holes guarantee a defined assignment of clamping elements by repeat setups. The tombstones conform to machine tables for machine tools acc. to DIN 55201 and JIS 6337-1980. Please order locating pins for positioning subplates on machine tables acc. to DIN 55201 separately. Please order protection plugs to plug unused grid holes separately. Ring bolts for hoisting are supplied. Other dimensions available on request. Drawing reference: 1) grid hole 2) hole for DIN 912 cap screw (D3/D4)

Request for a quote

NORELEM FRANCE

France

The UNI lock mounting clamps can be installed in any position on machine tables, fixtures or workholding equipment (tooling plates, cubes, tombstones etc). The modular design enables the number of clamps and distance between them to be ideally adjusted to suit the clamping task. The clamps can be supplied with or without rotation lock. The high clamping forces are generated by the integrated spring package (the unit clamps when depressurised). Compressed air is applied to release the clamp. The following holding forces are possible with the UNI lock clamping bolt in conjunction with M10, M12 or M16 fastening screws: Holding force (M10) 35,000N Holding force (M12) 50,000N Holding force (M16) 75,000N Supplied with: 1x clamping module incl. 6 fastening screws. 6x screw protection caps. 2x air connection O-rings. 1x installation O-ring.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine in which the placed parts are sandblasted with the rotation of the horizontally positioned circular table. It is preferred for sandblasting medium-sized parts that are not suitable for hanging.

Request for a quote

GRAVOTECH

France

LARGE MARKING POSSIBILITIES With its 3-sided door, the LW3 benefits from the best inside height dimensions and can securely envelop and mark parts up to 628 mm high. Thanks to its compatibility with our Fiber, Hybrid, Green industrial laser series, the LW3 can mark with high precision nearly every metal or plastic surfaces on its special positioning table. VERSATILE From unique identification marking, to multi-level engraving, and matrix marking on a batch of small to medium parts, this industrial laser station can mark your large part at several positions, and levels. Add a 3D module to your LW3 laser to mark sloped parts. INDUSTRY ORIENTED This laser marking machine is the only large laser engraver of the market with an attached touchscreen allowing the operator to easily manage the direct part marking process. In addition to the easy installation, manutention, and silent/ergonomic door opening, this class 1 laser stands out with its exceptional build quality.

Request for a quote

GRAVOTECH

France

OPEN STRUCTURE The M40 rotary engraver is 8.26x12in engraving area benefits from an open structure that allows larger items to be engraved when needed. Create custom engraving on very long plastic signage plates, electrical labels, thin wood beams, golf clubs, swords, irregular-shape items, and simply use as a sign engraver. GIFT ENGRAVING WITH THE M40 GIFT The M40 Gift includes an automatic lubricant tank and a rotary device to personalize glasses and bottles. The rotary device can be tilted for conical items. Engrave and personalize any flat or cylindrical items up to 4.33in height. BEGINNERS ROTARY ENGRAVER Control and adjust your work with our dedicated Gravostyle™ or ABC engraving software, thanks to several options. The M40 comes with an auto-centering jig and a laser beam (Point & Shoot) to help you place the item to engrave, while the engraving software automatically picks up its position. The included Gravogrip™ table firmly holds the item without leftover residue on it.

Request for a quote

AVM AUTOMATION

France

Manual XY positioning stage realized with leadscrew table 309L Manual XY positioning stage Tables 309L are assembled carriage on carriage (long carriage version only) with the option 308922 * making smooth holes in the carriage of a table. The standard strokes for each axis are 100, 200 or 300 mm. The same options as the 309L tables are available (handwheel, knob, indicator, locking, base plate). The choice of the type of guide is also the same (bronze or ball bushings). The axial positioning accuracy of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). Positioning tables with base plate Base plates are only available for standard strokes (100, 200 and 300mm). The lower plate allows the table to be fixed by the 4 holes in the central zone, while without a base plate, the table must be fixed by the end plates.

Request for a quote

AVM AUTOMATION

France

Economical manual positioning table drived by leadscrew. Actuated by grip knob. Guided by 2 rods on bronze bearings. Using of economical manual tables Acting is done by a grip knob supplied with the table. Maxi stroke is 100 mm for size 0, and 200 mm for sizes 1 and 2. Any nonstandard intermediate stroke can be produced. The locking in position is done on the trapezoidal screw, either in position B1 (above the front plate) or in position B2 (at the end of the end plate) depending on the access and the space available. The position is visualized by a mechanical indicator or by ruler on the base plate. The fixing on the frame is done by the 2 end plates (laminated holes) or by the end plate in « Z axis » version for vertical applications. The positioning accuracy of economical manual tables The axial positioning accuracy of these tables is <0.20 mm (in practice 0.05 to 0.15 mm), because the axial play is largely eliminated after locking in position

Request for a quote

AVM AUTOMATION

France

Positioning table for electric motor Guided by 2 rods on ball bushings Motor adaptation on linear table These ballscrew tables are delivered without motor, but the adaptation of your motor can be done by us. Some adaptations are standard, especially for standard motors (NEMA17 or NEMA23), if the dimensions of your motor are not listed, contact us to check the feasibility of your motor adaptation from our rough parts. Tables with ballscrew for motor The ballscrew is reversible and the axial precision of these tables is <0.07 mm. The maxi stroke is 400 mm, and any intermediate stroke can be produced. For a XY cross table, the tables are mounted on each other directly by the body with option 308922* (smooth holes are made in the body of a table). For less precise positioning applications, these tables are available with trapezoidal screw.

Request for a quote

AVM AUTOMATION

France

Positioning table for electric motor Guided by 2 rods on ball bushings (bronze bearings on request) Motor adaptation for linear table These leadscrew tables are delivered without motor, but the adaptation of your motor can be done by us. Some adaptations are standard, especially for standard motors (NEMA17 or NEMA23), if the dimensions of your motor are not listed, contact us to check the feasibility of your motor adaptation from our rough parts. Trapezoidal screw tables for motor The trapezoidal screw is irreversible and the axial precision of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). The maxi stroke is 750 mm, and any intermediate stroke can be produced. For a XY cross table, the tables are mounted on each other directly by the body with option 308922* (smooth holes are made in the body of a table). For more precise positioning applications, these tables are available with ballscrew.

Request for a quote

AVM AUTOMATION

France

Small manual positioning table Driving by metric screw M6x1 Guided by 2 rods in steel Precision and compactness of this small manual table It is the smallest manual table in our range (width 54 mm / height 27,5 mm). Screw step is 1 mm per round and axial precision of these tables is <0.05 mm after locking in position (<0,10 mm before locking in position). Locking in position is done on the transmission screw, either at the top of the bearing (position B1) or at the end of the table (position B2). Grip knob, position indicator and maxi stroke The shaft outlet is threaded to screw in the grip knob with or without a position indicator (or the handwheel, but it can’t be used with an indicator). The maxi stroke is 100 mm, and any intermediate stroke can be produced. Compact lifting table, miniature cross table and base plate A version « Z axis » allows to fix the table only by its end plate. It can be fixed directly on the carriage of another table for a YZ mounting.

Request for a quote

AVM AUTOMATION

France

Manual positioning table drived by lead screw Guided by 2 rods on bronze bearings or ball bushings Precision manual tables The guidance is ensured by 2 rods on 4 calibrated bronze bearings (reduced play) or 4 ball bushings for guidance without play. The guide length of long body tables (309L/M) allows to accept large loads and torques. The axial positioning accuracy of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). But the blocking in position is done on the carriage, by pressure on a guide rod, so as to remove the axial play of the nut of the trapezoidal screw after blocking. Manual crossed tables XY or YZ For the creation of XY crossed table, the tables are mounted one on the other directly by the body (long body version only) with the option 308922 * making smooth holes in the body of a table. To combine 2 tables in YZ, it is preferable to use a lifting table for the Z axis, mounted by its end on the body of the horizontal table.

Request for a quoteResults for

Positioning table - Import exportNumber of results

61 ProductsCountries

Company type

Category

- Mechanical transmission - components (11)

- Machine tools, metal machining - parts and accessories (10)

- Bearings, ball (7)

- Bearings - ball, needle and roller (4)

- Automation - systems and equipment (2)

- Joints, pneumatic (2)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (2)

- Sawing machine tools (2)

- Steel, special (2)

- Barbecues and accessories (1)

- Clamp collars, plastic (1)

- Conveyor systems (1)

- Crimping machines (1)

- Forming - steels and metals (1)

- Industrial washing facilities (1)

- Labelling machines (1)

- Laser - cutting and welding machines (1)

- Measurement - Equipment & Instruments (1)

- Measurement and control instruments (1)

- Metal engraving - machine tools (1)