- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- positioning table

Results for

Positioning table - Import export

AVM AUTOMATION

France

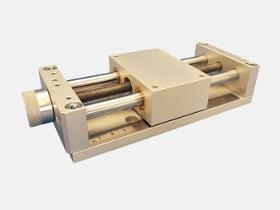

Manual positioning table drived by metric fine thread screw (pitch 1 - 1,25 mm). Actuated by grip knob. Guided by 2 rods on bronze bearings. Robust and economical table. Interchangeable with the 309B range. Options : Positioning indicator Position clamping Base plate (with or without ruler) Assembly in XY or YZ table

Request for a quote

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Grid spacing 50 ±0.02 mm. Tombstones with grid holes are used on horizontal machining centres. The alphanumerically labelled grid holes guarantee a defined assignment of clamping elements by repeat setups. The tombstones conform to machine tables for machine tools acc. to DIN 55201 and JIS 6337-1980. Please order locating pins for positioning subplates on machine tables acc. to DIN 55201 separately. Please order protection plugs to plug unused grid holes separately. Ring bolts for hoisting are supplied. Other dimensions available on request. Drawing reference: 1) grid hole 2) hole for DIN 912 cap screw (D3/D4)

Request for a quote

NORELEM FRANCE

France

Grid spacing 50 ±0.02 mm. Tombstones with grid holes are used on horizontal machining centres. The alphanumerically labelled grid holes guarantee a defined assignment of clamping elements by repeat setups. The tombstones conform to machine tables for machine tools acc. to DIN 55201 and JIS 6337-1980. Please order locating pins for positioning subplates on machine tables acc. to DIN 55201 separately. Please order protection plugs to plug unused grid holes separately. Ring bolts for hoisting are supplied. Other dimensions available on request. Drawing reference: 1) grid hole 2) hole for DIN 912 cap screw (D3/D4)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GRAVOTECH

France

LARGE MARKING POSSIBILITIES With its 3-sided door, the LW3 benefits from the best inside height dimensions and can securely envelop and mark parts up to 628 mm high. Thanks to its compatibility with our Fiber, Hybrid, Green industrial laser series, the LW3 can mark with high precision nearly every metal or plastic surfaces on its special positioning table. VERSATILE From unique identification marking, to multi-level engraving, and matrix marking on a batch of small to medium parts, this industrial laser station can mark your large part at several positions, and levels. Add a 3D module to your LW3 laser to mark sloped parts. INDUSTRY ORIENTED This laser marking machine is the only large laser engraver of the market with an attached touchscreen allowing the operator to easily manage the direct part marking process. In addition to the easy installation, manutention, and silent/ergonomic door opening, this class 1 laser stands out with its exceptional build quality.

Request for a quote

GRAVOTECH

France

OPEN STRUCTURE The M40 rotary engraver is 8.26x12in engraving area benefits from an open structure that allows larger items to be engraved when needed. Create custom engraving on very long plastic signage plates, electrical labels, thin wood beams, golf clubs, swords, irregular-shape items, and simply use as a sign engraver. GIFT ENGRAVING WITH THE M40 GIFT The M40 Gift includes an automatic lubricant tank and a rotary device to personalize glasses and bottles. The rotary device can be tilted for conical items. Engrave and personalize any flat or cylindrical items up to 4.33in height. BEGINNERS ROTARY ENGRAVER Control and adjust your work with our dedicated Gravostyle™ or ABC engraving software, thanks to several options. The M40 comes with an auto-centering jig and a laser beam (Point & Shoot) to help you place the item to engrave, while the engraving software automatically picks up its position. The included Gravogrip™ table firmly holds the item without leftover residue on it.

Request for a quote

AVM AUTOMATION

France

Manual XY positioning stage realized with leadscrew table 309L Manual XY positioning stage Tables 309L are assembled carriage on carriage (long carriage version only) with the option 308922 * making smooth holes in the carriage of a table. The standard strokes for each axis are 100, 200 or 300 mm. The same options as the 309L tables are available (handwheel, knob, indicator, locking, base plate). The choice of the type of guide is also the same (bronze or ball bushings). The axial positioning accuracy of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). Positioning tables with base plate Base plates are only available for standard strokes (100, 200 and 300mm). The lower plate allows the table to be fixed by the 4 holes in the central zone, while without a base plate, the table must be fixed by the end plates.

Request for a quote

AVM AUTOMATION

France

Economical manual positioning table drived by leadscrew. Actuated by grip knob. Guided by 2 rods on bronze bearings. Using of economical manual tables Acting is done by a grip knob supplied with the table. Maxi stroke is 100 mm for size 0, and 200 mm for sizes 1 and 2. Any nonstandard intermediate stroke can be produced. The locking in position is done on the trapezoidal screw, either in position B1 (above the front plate) or in position B2 (at the end of the end plate) depending on the access and the space available. The position is visualized by a mechanical indicator or by ruler on the base plate. The fixing on the frame is done by the 2 end plates (laminated holes) or by the end plate in « Z axis » version for vertical applications. The positioning accuracy of economical manual tables The axial positioning accuracy of these tables is <0.20 mm (in practice 0.05 to 0.15 mm), because the axial play is largely eliminated after locking in position

Request for a quote

AVM AUTOMATION

France

Positioning table for electric motor Guided by 2 rods on ball bushings (bronze bearings on request) Motor adaptation for linear table These leadscrew tables are delivered without motor, but the adaptation of your motor can be done by us. Some adaptations are standard, especially for standard motors (NEMA17 or NEMA23), if the dimensions of your motor are not listed, contact us to check the feasibility of your motor adaptation from our rough parts. Trapezoidal screw tables for motor The trapezoidal screw is irreversible and the axial precision of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). The maxi stroke is 750 mm, and any intermediate stroke can be produced. For a XY cross table, the tables are mounted on each other directly by the body with option 308922* (smooth holes are made in the body of a table). For more precise positioning applications, these tables are available with ballscrew.

Request for a quote

AVM AUTOMATION

France

Positioning table for electric motor Guided by 2 rods on ball bushings Motor adaptation on linear table These ballscrew tables are delivered without motor, but the adaptation of your motor can be done by us. Some adaptations are standard, especially for standard motors (NEMA17 or NEMA23), if the dimensions of your motor are not listed, contact us to check the feasibility of your motor adaptation from our rough parts. Tables with ballscrew for motor The ballscrew is reversible and the axial precision of these tables is <0.07 mm. The maxi stroke is 400 mm, and any intermediate stroke can be produced. For a XY cross table, the tables are mounted on each other directly by the body with option 308922* (smooth holes are made in the body of a table). For less precise positioning applications, these tables are available with trapezoidal screw.

Request for a quote

AVM AUTOMATION

France

Small manual positioning table Driving by metric screw M6x1 Guided by 2 rods in steel Precision and compactness of this small manual table It is the smallest manual table in our range (width 54 mm / height 27,5 mm). Screw step is 1 mm per round and axial precision of these tables is <0.05 mm after locking in position (<0,10 mm before locking in position). Locking in position is done on the transmission screw, either at the top of the bearing (position B1) or at the end of the table (position B2). Grip knob, position indicator and maxi stroke The shaft outlet is threaded to screw in the grip knob with or without a position indicator (or the handwheel, but it can’t be used with an indicator). The maxi stroke is 100 mm, and any intermediate stroke can be produced. Compact lifting table, miniature cross table and base plate A version « Z axis » allows to fix the table only by its end plate. It can be fixed directly on the carriage of another table for a YZ mounting.

Request for a quote

AVM AUTOMATION

France

Manual positioning table drived by lead screw Guided by 2 rods on bronze bearings or ball bushings Precision manual tables The guidance is ensured by 2 rods on 4 calibrated bronze bearings (reduced play) or 4 ball bushings for guidance without play. The guide length of long body tables (309L/M) allows to accept large loads and torques. The axial positioning accuracy of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). But the blocking in position is done on the carriage, by pressure on a guide rod, so as to remove the axial play of the nut of the trapezoidal screw after blocking. Manual crossed tables XY or YZ For the creation of XY crossed table, the tables are mounted one on the other directly by the body (long body version only) with the option 308922 * making smooth holes in the body of a table. To combine 2 tables in YZ, it is preferable to use a lifting table for the Z axis, mounted by its end on the body of the horizontal table.

Request for a quote

AVM AUTOMATION

France

Manual table with double carriage with reversed step (the 2 carriages move away or get closer) Driving by leadscrew Guided by 2 rods Interest of table with reversed step The two carriages move away or get closer symmetrically during the rotation of the trapezoidal screw thanks to right and lefthand thread, this allows for example to adjust the spacing of the outer guides of a conveyor according to the type of product transported. Precision and robustness of right and lefthand thread table The guidance is provided by 2 rods on 4 calibrated bronze bearings (reduced play) or 4 ball bushings for guidance without clearance. The guide length of long body tables (309N/P) allows to accept large loads and torques. The axial positioning accuracy of these tables is <0.15 mm (in practice 0.02 to 0.10 mm). But the blocking in position is done on the carriage, by pressure on a guide rod, so as to remove the axial play of the nut of the trapezoidal screw after blocking

Request for a quoteResults for

Positioning table - Import exportNumber of results

15 ProductsCountries

Company type