- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- oil seal rings

Results for

Oil seal rings - Import export

REP INTERNATIONAL

France

THP range machines are particularly appropriate for the molding of oil seals, backup rings, parts for the automotive industry and many other rubber parts. There are two series, 2RT or 3RT, depending on the number of mold platens. Of simple design for easy maintenance, they can be provided as single or double station machine. Their vacuum cover design allows for reduced curing time and therefore increased profitability. The top platen, which is inclined by 60°, is suitable for different demolding options.

Request for a quote

DUTCH PERFORMANCE PRODUCTS VOF

Netherlands

The Lindemann Oil Stop Leak contains an additional agent that returns rubber oil seals and o-rings and also plastic parts that have been ” hardened ” back to the original flexibility so that they regain their original function. This is not part of the Lindemann Worn Engine Treatment! This is also the difference between the two products

Request for a quote

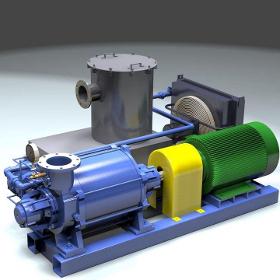

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

ORing in material NBR, FKM, FFKM, VMQ, EPDM, ect.

Request for a quote

PEEKCHINA CO., LTD.

China

Engineered to optimize assembly processes, our PEEK lock ring (PEEK locating ring) offers superior alignment and stability, enhancing the performance of industrial machinery. With its durable construction and reliable positioning, it ensures long-lasting performance even in the most demanding environments.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Spherical valves are installed upstream of the turbine as shutoff devices specifically for high pressures at the end of the penstock. Their main function is to close off the penstock during normal shutdown or load shedding of the turbine. The seal is a metal sliding ring which is generally moved by water hydraulics. The MANOY® system seal WP, type 434 (outer sealing) and the inner sealing type 439, were developed for sealing of the sliding ring. The profile dimensions can be customized for maintenance or specific requirements.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK Seal Material Our PEEK pipe sealing elements redefine reliability for valve seat inserts. Crafted from high-grade PEEK material, these inserts offer exceptional resistance to temperature variations, chemicals, and pressure, ensuring leak-free and durable sealing solutions for your valves.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Hydraulic and pneumatic cylinders, Presses, Shock absorbers, Fittings, Controls, Piston and plunger pumps, Mobile hydraulics, Injection units

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Hydraulic and pneumatic cylinders, Presses, Shock absorbers, Fittings, Controls, Piston and plunger pumps, Mobile hydraulics, Injection units

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Face seal used for rotary and oscillating motion in pipe joints and rotary actuators. Used at low to high pressure and low speed

Request for a quote

NORELEM FRANCE

France

Orings are universal sealing elements used to seal against liquid or gaseous median. They are suitable for static and minor dynamic applications. Orings can be used for radial and axial sealing. The sealing occurs during installation by the radial or axial compression of the crosssection. During operation, the median pressure increases the deformation of the Oring and so increases the sealing effectiveness. For best sealing effectiveness, the Oring should have the largest possible crosssection. During installation the correct groove size, compaction, elongation/compression should be ensured. By static use the compaction should be 15 30% of the crosssection. By dynamic use it should be 10 18% (hydraulic), 4 12% (pneumatic). With regard to the ID, when installed the Oring should be stretched max 6% compressed max 3%

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK Ring Our PEEK Rings are engineered to deliver superior sealing and insulation solutions for a wide range of applications. With exceptional chemical resistance and durability, these rings excel in demanding environments, providing long-lasting reliability for critical sealing needs. Whether you require standard options or custom-tailored solutions, our PEEK Rings offer low maintenance, high reliability, and the assurance of precision sealing. Elevate your sealing capabilities with confidence in the quality and performance of PEEK Rings.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

The X‑ring is a continuous, seamless vulcanized ring with a special profile which is derived from four O‑rings arranged in a square crosssection.The particular advantage of the X‑ring is that it cannot roll or twist. The squeeze required to maintain an effective seal is also relatively low.The X‑ring is used in mechanical and automotive engineering, preferably as a static radial or static axial seal. Other applications are for linear or rotary motion of plungers, pistons, tappets, dampers and valve, bearing and piston rods, etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing. Applications: Electrical transmission and distribution Electronics industry Textile machinery Defense Medical electronics Automobile industry Sealing Solid Oxide Fuel Cells High temperature application

Request for a quote

LBI

France

We manufacture rough or fully balancing & sealing ring in stainless steels and copper based alloys. Large diameter and thin section parts. High dimensional stability resulting from the low and balanced internal stress.

Request for a quote

LBI

France

We manufacture rough or fully machined seat and sealing ring for ball and butterfly valves in : • Austenitic stainless steel Alloys (CF8M, CF3M…) • Aluminium-Bronze (UNS C95500…) • Duplex and Super Duplex (CD4MCu, CD3MN…) • Nickel-based and high-alloys (CW-6MC, CU5MCuC, M-35-1 CW-12MW…) • Martensitic alloys (CA15, CA6NM…) • Other materials on request

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EKON HYDRAULICS & RUBBER

Turkey

Compatible Seals and spare parts available in our stocks.

Request for a quoteResults for

Oil seal rings - Import exportNumber of results

19 ProductsCountries