- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- oil seal rings

Results for

Oil seal rings - Import export

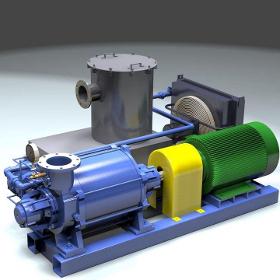

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quote

NORELEM FRANCE

France

Orings are universal sealing elements used to seal against liquid or gaseous median. They are suitable for static and minor dynamic applications. Orings can be used for radial and axial sealing. The sealing occurs during installation by the radial or axial compression of the crosssection. During operation, the median pressure increases the deformation of the Oring and so increases the sealing effectiveness. For best sealing effectiveness, the Oring should have the largest possible crosssection. During installation the correct groove size, compaction, elongation/compression should be ensured. By static use the compaction should be 15 30% of the crosssection. By dynamic use it should be 10 18% (hydraulic), 4 12% (pneumatic). With regard to the ID, when installed the Oring should be stretched max 6% compressed max 3%

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Oil seal rings - Import exportNumber of results

2 ProductsCountries

Company type

Category