- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- turnkey solution

Results for

Turnkey solution - Import export

SAMAG MACHINE TOOLS GMBH

Germany

PROCESS-RELIABLE SOLUTIONS FOR HIGH VOLUMES – EFFICIENT PRODUCTION WITH MINIMAL UNIT COSTS. The automotive industry is the ultimate challenge with its range of parts and performance indicators. Only innovative machine concepts are solutions that ensure efficiency in the process. Companies from the vehicle and supplier industries worldwide therefore successfully use SAMAG machining centers and production machines, including turnkey solutions. High precision, reliability, automation and cost optimization are among the key automotive requirements.

Request for a quote

QUELLTECH GMBH

Germany

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The reclamation of valuable resources from electrical and electronic scrap – a global volume in excess of 40 million tonnes/year – is one of the greatest challenges facing our society. With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets. For many years now, ERDWICH has specialised in the reclamation of valuable primary materials from electronic waste with its turnkey system solutions. ERDWICH pre-processing: All process execution is fully compliant with the new DIN EN 50625/1 rules. Whether you need to handle electrics/electronics, small/large household appliances or specialist items such as fluorescent lamps, PCBs, LCD monitors and PV modules, whether as a mobile or stationary solution: create new value from electronic waste with ERDWICH. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your...

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

One of the greatest challenges facing our society is the reclamation of valuable raw materials from electrical and electronic scrap. A global scrap volume exceeding 40 million tonnes a year – a figure forecast to double by 2025 – presents both a challenge and an opportunity. Since even in Germany only some 40% of scrap is currently fed into a waste management process, we may assume that the global rate of waste management is still substantially lower. With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets. For many years now, ERDWICH has specialised in the reclamation of valuable primary materials from electronic waste with its shredding machinery and turnkey plant solutions. As a result, economical and mature solutions are available for meeting any of these challenges. ERDWICH pre-processing: Whether you’re handling electrical/electronic waste, small/large household appliances,...

Request for a quote

BORSIG GMBH

Germany

With around 160 years of manufacturing expertise in reciprocating compressors, BORSIG offers tailor-made horizontal and vertical compressor solutions for process gases with all auxiliary equipment (turnkey solutions). Our reciprocating compressors are driven either by electric motors, gas engines or steam turbines. They have been developed for heavy continuous operation with lubricated or non-lubricated cylinders. They comply with the design standards of API 618 (5th edition), API 11P/ ISO 13631 as well as other international and manufacturing standards. BORSIG reciprocating compressors stand for long life, high wear resistance and low life cycle costs.

Request for a quote

BORSIG GMBH

Germany

BORSIG has been manufacturing centrifugal compressors for process gases for almost 60 years. The BORSIG centrifugal compressor series comprises multistage integrally geared centrifugal compressors with up to 8 stages, with steam turbine, gas turbine or electric motor as driver with all auxiliary equipment (turnkey solutions) according to customer’s requirements. The compressors comply with the corresponding API design standards such as API 617 (chapter 3) and 672 (4th edition). The oil system is designed according to API 614 or manufacturer's standard. The development is based on the latest research results in fluid mechanics as well as in gear and bearing design.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology supplies customised plants and systems for the food and luxury food industry up to complete turnkey solutions. Reproducibility and accuracy are the hallmarks of our plants and systems in the food industry and the luxury food industry. Another focus is on hygiene and diligence: Plants from IFA Technology are made of high quality stainless steel and use food grade materials and FDA approved (Food and Drug Administration) components. The plant components and their functions are adapted to the necessary requirements of the end customers and fulfil the requirements of the specific certifications.

Request for a quote

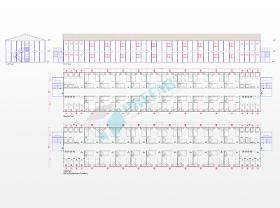

PREFABEX MODULAR BUILDING SOLUTIONS

Turkey

Prefabex prefabricated modular dormitory buildings have a variety of applications in different areas, including: residential and student accommodation, construction worksites, Sports complexes, Mining industry facilities, manufacturing facilities, Camping grounds, Factories, worksite camps, Agricultural sites, and Manufacturing facilities. Let Prefabex fully assess your specific requirement for prefabricated sleeping accommodation buildings and suggest the best turnkey solution for your location and staff sleeping accommodation requirements whilst respecting your budget expectations. Our modular dormitory is made up of volumetric units that are efficiently assembled in a factory-like setting. Whatever your portable accommodation needs and whatever your budget we will suggest a solution that meets your exact needs. All of the temporary site sleeping accommodation we design and build are to the highest standard and to the unique and specific requirements of our clients.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP drinking water tanks for water supply companies are offered together with our project partner Kurz Leitungsbau GmbH. In doing so, we meet the highest standards applicable to the supply of drinking water, from planning and conception up to construction. Our automated welding process for high alloy stainless steels based on the LIPP System enables us to offer tanks with a maximum volume of 10,000 m3. In addition, on site production “off the production line” enables construction to be completed within the shortest possible time. Optimum quality thanks to automated welding process Material savings and additional stability thanks to circumferential profile Short construction times thanks to mechanised production Easy to maintain and clean Low investment and maintenance costs Can be set up indoors or in the open air Turnkey complete solution or components

Request for a quote

FRIMO GROUP GMBH

Germany

Flexible and individual solutions FRIMO offers many different solutions in terms of combining tool carriers, mix and metering units, and the peripheral equipment necessary to complete production plants. Individual and turnkey production solutions are therefore highly available.

Request for a quote

ERDEMLER COOLING COMPANY

Turkey

As Erdemler Soğutma, we provide design, manufacturing, installation, aftersales service and maintenance services for our customers slaughterhouse and meat processing systems. We provide turnkey solutions in automation level. Modern cutting and meat processing systems are combining cold room systems for cattle, sheep, and chickens with automation technology. Our company gives importance to animal welfare, quality, safety, hygiene, and ergonomy by providing the highquality services. Our efficiency guarantees for competitive power to our customers.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

We specialize in engineering high quality composites for management of heat in electronics packages, particularly Integrated Circuit (IC) packaging. These composite materials are comprised of Molybdenum Copper (AMC) and Tungsten Copper (AWC). Turnkey Solution for Production Ready Pedestals Our advanced thermal management materials are offered both in a raw form such as block or sheet for finished machining at our customers’ facilities or their sub-tier suppliers. We also offer turnkey finished products completed through machining, plating and customer specified packaging. Sizes Our heat spreader materials for IC packages are offered in a wide breadth of sizes including: Standard blocks of 3” (76 mm) x 4” (102 mm) x 12” (304.8mm) Down to finished machined and plated products in 0.015” (0.381mm) cubes Hermetic Housings and Heat Sinks These thermal management products are used as both the hermetic housings and as the expansion-matched

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products has led the industry in the production of Pfinodal® (C72900), a highly specialized Spinodal alloy, with superior bearing properties. Our production processes and heat treatments combine to ensure the high hardness required in tough drill bit material for bearing components such as sleeves, bushings, washers and caps. Our Pfinodal® (C72900) bearing materials has been in use for 20 years under patent numbers 5527113 and 5552106 for these rock bit bearing applications. Advantages The near-net shape processing of our Spinodal materials eliminates waste thereby reducing cost for the finished product. We specialize in offering the turnkey solutions of materials that are machined, plated and packaged to your specifications. These can be shipped to your facilities around the world for incorporation in the bits, reamers and equipment needed to power the world.

Request for a quote

ERDEMLER COOLING COMPANY

Turkey

The start of the production of vaccines developed against Covid19 has increased the needs in both logistics and storage. Unlike other vaccines, some of Covid19 vaccines must be stored at minus 70 degrees Celsius. As standard vaccines are stored at 2 to 8 degrees celcius, existing storage areas are not suitable for some of the Covid19 vaccines. As Erdemler Cooling, we have developed solutions to eliminate the cold chain and storage problems in order to reach all Covid19 vaccines developed in the World to the end user in a healthy way. These developments include mobile container type vaccine cold storage and fixed logistic vaccine storages. We offer turnkey solutions for all institutions such as healthcare institutions, hospitals, laboratories, logistics warehouses, pharmaceutical companies, and research institutions that need these special cold storages. You can contact us for details.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

We manufacture bar and tube products in our corrosion resistant Spinodal alloy, Pfinodal® (C72900), for use in downhole housings, centralizers, and joints that operate in demanding subsea environments. Advantages Our Copper nickel tin Pfinodal® (C72900) bar and tube products present a combination of unique properties that deliver significant advantages for downhole oil and gas applications. Non-sparking and non-magnetic Anti-galling Anti-corrosive Heat treatable to high hardness Safe alternative to Beryllium Copper (BeCu) Pfinodal ® (C72900) Bar and Tube C72900 copper alloy materials are available in bar and tube sizes up to 6” (152.4mm) diameters as well as in both strip and plate products. Our C72900 material is generally provided as machining bar in the aged condition with many sizes available to ship from inventory. We also offer the ability to provide turnkey solutions by providing fully machined parts to OEM drawings.

Request for a quote

BETONBAU GMBH UND CO. KG

Germany

Type AW 30 concrete basin, overviews An example of a concrete basin selected from our UF series modular system is illustrated here. This enables the realisation of single and multi-component transformer stations. Systems are generally delivered as turnkey solutions (i.e. with supporting structures for tracks, fire protection grid and false floor). Other ground plans can be realised from our versatile range in the entire UF series.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DE SMET ENGINEERS & CONTRACTORS

Belgium

DSEC is your trusted partner for the construction of your biomass energy plants. Biomass to energy via cogeneration is a sustainable power source, its valorisation can be done trough many different processes. The choice for the suitable technology depends on its various characteristics (moisture, size, ashes melting point, chlorine content, ashes content, ...). Several applications can be developed, from heat production to power generation or even combined heat and power plant. Through its numerous references in biomass valorization, DSEC is able to provide the right expertise to the customer. De Smet Engineers & Contractors is an actor into the green heat and electricity field, developing realizations from concept to start-up. Thanks to our wide turnkey experience, we may give warranties on the schedule, the investment and the performances. Developed biomass energy via cogeneration projects concern pellet production, biomethanisation, wood chips gasification, straw combustion, sunflower husks, bagasse and other agricultural residues valorization for direct steam production or electricity production with back pressure or condensing turbine. De Smet Engineers and Contractors offers you turnkey solutions fitting with your specific needs, that can start with Conceptual Engineering and FEED studies and finally evolve into a Full EPC biomass energy plant project.

Request for a quote

BETONBAU GMBH UND CO. KG

Germany

Delivery The organisation and realisation of large-volume modular unit transportation is our metier. Thousands of stations and modular units leave our plants every year and are delivered reliably and safely to their destinations. Transporation of modular units with dimensions up to 4.20 m in width or up to 12 m in length and with a height of over 3.60 m is part and parcel of our daily business. Although this is routine for us, enormous care is exercised and safety taken extremely seriously, beginning with safe loading and continuing during farsighted planning of the route. Our five production locations provide nationwide coverage, thus short transportation routes also help preserve the environment and avoid long journeys. We can also reliably deliver your module in practically any kind of weather - and fit it out in advance in our plant if desired. Whether our products are prepared to facilitate installation, or delivery and installation as a turnkey solution: we also provide...

Request for a quote

FILLTECH GMBH

Germany

Costumer specific systems and Turnkey-Solutions Filltech designs, produces and implements fully automated gas filling solutions for the medical, consumer, industrial and special gas industry. All fully automated filling systems have been developed in close cooperation with the customer to ensure the best possible solution for their specific needs. Advantages Design of fully or semi-automated filling stations (in-house or in strong cooperation with your engineering team) One-stop-station for all necessary handling: emptying, cleaning, filling, weighing, leakage control, sealing and shielding In-house production of all filling stations Implementation at your premises Education at your premises 24/7 Back-up support available General capacity: 1000 CO 2 cylinders/hour IT-integration with your systems Track & Trace Ergonomic approach Conversions to AD2000 DIN/ISO 9001 ISO 22000 Module AI in accordance with RL 97/23/EG PED The following products might also be of interest to you: CO 2

Request for a quote

DRALLIM INDUSTRIES LIMITED

United Kingdom

Our highly skilled staff specialise in solving the sort of engineering and manufacturing conundrums you’d rather do without. Our organisation is geared to producing one-off’s; We take pride in overseeing the entire process, from design, prototyping and manufacture to delivery, installation, full product certification and after-sales service. With experience in providing comprehensive turnkey assembly test solutions covering electronic, electromechanical, engineering and mechanical products we offer our customers a total contract manufacturing service. We are a leading innovator in design and manufacturing solutions, providing engineering skills, manufactured equipment & custom-built systems for the Aerospace, Industrial and Utility Markets.

Request for a quote

DRALLIM INDUSTRIES LIMITED

United Kingdom

Our skilled staff specialise in solving the sort of engineering and manufacturing conundrums you’d rather do without. Our organisation is geared to producing one-off prototypes and small batch manufacturing; We take pride in overseeing the entire process, from design, prototyping and manufacture to delivery, installation, full product certification and after-sales service. With experience in providing comprehensive turnkey assembly test solutions covering electronic, electromechanical, engineering and mechanical products we offer our customers a total contract manufacturing service. When an order is received, a project plan is then developed; our team uses detailed documentation, engineering change and reporting control to ensure continued information integrity. An experienced project manager acts as the interface between Drallim and our customers although, at the same time, we actively encourage engineer-to-engineer communication.

Request for a quote

BLUE ASSOCIATES SPORTSWEAR

United Kingdom

We design, develop, source and produce sportswear for our clients from large sportswear brands through to start ups with a great idea. Small MOQ possible and a full turnkey solution for anyone looking to start a sportswear brand from branding, logos, product design, specifications, samples, production, crowdfunding, and marketing support. Established in 1997

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

ONE Line TWO Methods Coil Fed Shear Blanking & Laser Cutting Line The Blanking Line cuts all your custom blanks direct from the coil with our turnkey solutions, utilising automation for feeding levelling cutting and stacking of all cut parts. Shear Cutting provides rapid cutting of blanks at any size Laser Cutting offers high speed cutting straight lines, trapezoid and any shape blanks for your production requirements

Request for a quote

ACIMEX

France

Bespoke machines are pieces of equipment installed on production lines (handling line, output line, etc.) and which are used to move different types of heavy loads from point A to point B (storage area). ACIMEX is specialized in the manufacture of equipment fitted with suction cups which detect the weight, the diameter and the size of heavy loads in order to grip them in complete safety and so facilitate the production process. Using its know-how in custom design and manufacture, ACIMEX innovates constantly to create bespoke machines that meet the needs of each of its customers. Two types of bespoke machines have been developped at the beginning of 2017 in ACIMEX factories, one to grip sandwich panels of 160 kg safely, and the other to move and store graphite electrodes. Evidence, once again, that ACIMEX offers turnkey solutions to its customers, and this regardless of the type of handling performed.

Request for a quote

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Gently objective handling Simple operation Continuously working Processability of all commercial closures Small amount of format parts Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

ATEX model optional Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Simple operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Results for

Turnkey solution - Import exportNumber of results

80 ProductsCountries

Company type

Category

- Pharmaceutical industry - machinery and equipment (27)

- Chemical and pharmaceutical industry - machinery and equipment (6)

- Boilers, industrial (4)

- Software (4)

- Packing and packaging - machinery and equipment (3)

- Steel & Metals (3)

- Cold rooms (2)

- Compressors (2)

- Hardware, building construction (2)

- Automation - systems and equipment (1)

- Buildings, prefabricated (1)

- Cosmetics (1)

- Designers (1)

- Flour milling - machinery and equipment (1)

- Flour-milling (1)

- Food industry - machinery and equipment (1)

- Goods handling systems, continuous (1)

- Heat recovery systems (1)

- Laser - cutting and welding machines (1)

- Lifting equipment (1)