- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- turnkey solution

Results for

Turnkey solution - Import export

SAMAG MACHINE TOOLS GMBH

Germany

PROCESS-RELIABLE SOLUTIONS FOR HIGH VOLUMES – EFFICIENT PRODUCTION WITH MINIMAL UNIT COSTS. The automotive industry is the ultimate challenge with its range of parts and performance indicators. Only innovative machine concepts are solutions that ensure efficiency in the process. Companies from the vehicle and supplier industries worldwide therefore successfully use SAMAG machining centers and production machines, including turnkey solutions. High precision, reliability, automation and cost optimization are among the key automotive requirements.

Request for a quote

QUELLTECH GMBH

Germany

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The reclamation of valuable resources from electrical and electronic scrap – a global volume in excess of 40 million tonnes/year – is one of the greatest challenges facing our society. With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets. For many years now, ERDWICH has specialised in the reclamation of valuable primary materials from electronic waste with its turnkey system solutions. ERDWICH pre-processing: All process execution is fully compliant with the new DIN EN 50625/1 rules. Whether you need to handle electrics/electronics, small/large household appliances or specialist items such as fluorescent lamps, PCBs, LCD monitors and PV modules, whether as a mobile or stationary solution: create new value from electronic waste with ERDWICH. To get an idea of what we’re capable of, please see the following Case Studies. Now it’s your turn: we look forward to receiving your...

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

One of the greatest challenges facing our society is the reclamation of valuable raw materials from electrical and electronic scrap. A global scrap volume exceeding 40 million tonnes a year – a figure forecast to double by 2025 – presents both a challenge and an opportunity. Since even in Germany only some 40% of scrap is currently fed into a waste management process, we may assume that the global rate of waste management is still substantially lower. With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets. For many years now, ERDWICH has specialised in the reclamation of valuable primary materials from electronic waste with its shredding machinery and turnkey plant solutions. As a result, economical and mature solutions are available for meeting any of these challenges. ERDWICH pre-processing: Whether you’re handling electrical/electronic waste, small/large household appliances,...

Request for a quote

BORSIG GMBH

Germany

With around 160 years of manufacturing expertise in reciprocating compressors, BORSIG offers tailor-made horizontal and vertical compressor solutions for process gases with all auxiliary equipment (turnkey solutions). Our reciprocating compressors are driven either by electric motors, gas engines or steam turbines. They have been developed for heavy continuous operation with lubricated or non-lubricated cylinders. They comply with the design standards of API 618 (5th edition), API 11P/ ISO 13631 as well as other international and manufacturing standards. BORSIG reciprocating compressors stand for long life, high wear resistance and low life cycle costs.

Request for a quote

BORSIG GMBH

Germany

BORSIG has been manufacturing centrifugal compressors for process gases for almost 60 years. The BORSIG centrifugal compressor series comprises multistage integrally geared centrifugal compressors with up to 8 stages, with steam turbine, gas turbine or electric motor as driver with all auxiliary equipment (turnkey solutions) according to customer’s requirements. The compressors comply with the corresponding API design standards such as API 617 (chapter 3) and 672 (4th edition). The oil system is designed according to API 614 or manufacturer's standard. The development is based on the latest research results in fluid mechanics as well as in gear and bearing design.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology supplies customised plants and systems for the food and luxury food industry up to complete turnkey solutions. Reproducibility and accuracy are the hallmarks of our plants and systems in the food industry and the luxury food industry. Another focus is on hygiene and diligence: Plants from IFA Technology are made of high quality stainless steel and use food grade materials and FDA approved (Food and Drug Administration) components. The plant components and their functions are adapted to the necessary requirements of the end customers and fulfil the requirements of the specific certifications.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP drinking water tanks for water supply companies are offered together with our project partner Kurz Leitungsbau GmbH. In doing so, we meet the highest standards applicable to the supply of drinking water, from planning and conception up to construction. Our automated welding process for high alloy stainless steels based on the LIPP System enables us to offer tanks with a maximum volume of 10,000 m3. In addition, on site production “off the production line” enables construction to be completed within the shortest possible time. Optimum quality thanks to automated welding process Material savings and additional stability thanks to circumferential profile Short construction times thanks to mechanised production Easy to maintain and clean Low investment and maintenance costs Can be set up indoors or in the open air Turnkey complete solution or components

Request for a quote

FRIMO GROUP GMBH

Germany

Flexible and individual solutions FRIMO offers many different solutions in terms of combining tool carriers, mix and metering units, and the peripheral equipment necessary to complete production plants. Individual and turnkey production solutions are therefore highly available.

Request for a quote

BETONBAU GMBH UND CO. KG

Germany

Type AW 30 concrete basin, overviews An example of a concrete basin selected from our UF series modular system is illustrated here. This enables the realisation of single and multi-component transformer stations. Systems are generally delivered as turnkey solutions (i.e. with supporting structures for tracks, fire protection grid and false floor). Other ground plans can be realised from our versatile range in the entire UF series.

Request for a quote

BETONBAU GMBH UND CO. KG

Germany

Delivery The organisation and realisation of large-volume modular unit transportation is our metier. Thousands of stations and modular units leave our plants every year and are delivered reliably and safely to their destinations. Transporation of modular units with dimensions up to 4.20 m in width or up to 12 m in length and with a height of over 3.60 m is part and parcel of our daily business. Although this is routine for us, enormous care is exercised and safety taken extremely seriously, beginning with safe loading and continuing during farsighted planning of the route. Our five production locations provide nationwide coverage, thus short transportation routes also help preserve the environment and avoid long journeys. We can also reliably deliver your module in practically any kind of weather - and fit it out in advance in our plant if desired. Whether our products are prepared to facilitate installation, or delivery and installation as a turnkey solution: we also provide...

Request for a quote

FILLTECH GMBH

Germany

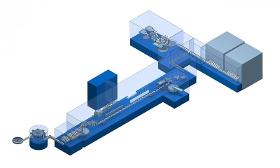

Costumer specific systems and Turnkey-Solutions Filltech designs, produces and implements fully automated gas filling solutions for the medical, consumer, industrial and special gas industry. All fully automated filling systems have been developed in close cooperation with the customer to ensure the best possible solution for their specific needs. Advantages Design of fully or semi-automated filling stations (in-house or in strong cooperation with your engineering team) One-stop-station for all necessary handling: emptying, cleaning, filling, weighing, leakage control, sealing and shielding In-house production of all filling stations Implementation at your premises Education at your premises 24/7 Back-up support available General capacity: 1000 CO 2 cylinders/hour IT-integration with your systems Track & Trace Ergonomic approach Conversions to AD2000 DIN/ISO 9001 ISO 22000 Module AI in accordance with RL 97/23/EG PED The following products might also be of interest to you: CO 2

Request for a quote

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Gently objective handling Simple operation Continuously working Processability of all commercial closures Small amount of format parts Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

ATEX model optional Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Simple operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Simple operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Do you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available syringes nested in tubs and bags Aseptic fields of application Processability of three different container types (vials, cartridges and syringes) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Gently objective handling Simple operation Intermittent operation Ultrasound pretreatment optional Small amount of format parts Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Processability of three different container types (vials, cartridges and syringes) Simple operation First-in-first-out principle Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Simple operation Appropriate for small batch production and laboratory applications Continuously working Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Gently objective handling Simple operation Intermittent operation or continuously working Ultrasound pretreatment optional Very good ability to be cleaned Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

1-lane supply All commercially available ready-to-use syringes (glass and plastic) Simple operation Nested syringes Intermittent operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

1-lane supply All commercially available ready-to-use syringes (glass and plastic) Simple operation First-in-first-out principle Intermittent operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Simple operation Intermittent operation Compact design Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Results for

Turnkey solution - Import exportNumber of results

48 ProductsCountries

Company type

Category

- Pharmaceutical industry - machinery and equipment (27)

- Chemical and pharmaceutical industry - machinery and equipment (5)

- Packing and packaging - machinery and equipment (3)

- Compressors (2)

- Goods handling systems, continuous (1)

- Mechanical engineering - custom work (1)

- Optical measuring equipment (1)

- Packaging (1)

- Tanks, metal (1)

- Waste treatment and recycling - machines and installations (1)