- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- core drilling

Results for

Core drilling - Import export

RHODIUS ABRASIVES GMBH

Germany

Core drill for concrete and high-density limestone. • Can be used with fitting accessories CDS • Extremely long service life • High cutting speed

RHODIUS ABRASIVES GMBH

Germany

Special socket driller with back holes for controlled dust extraction in occupied rooms. Very good cooling of the segments and significant wear reduction due to immediate disposal of waste material. The diamond core drill runs more smoothly and does not jam thanks to less friction at the outer wall. Significantly reduced dust development. • Universal application in old and new constructions • Particularly suitable for indoor applications • Matching extraction 304018

RHODIUS ABRASIVES GMBH

Germany

Matching accessory for CD10 / CD20 core drill. • Matched to core drill

RHODIUS ABRASIVES GMBH

Germany

Tile drill bit for use on angle grinders with an M14 thread. • Cool cut through internal cooling wax • Excellent service life • High cutting speed

RHODIUS ABRASIVES GMBH

Germany

Tile drill bit for use on drills with a ¼” bit adapter. • Cool cut through internal cooling wax • Excellent service life • High cutting speed

ÖRNEK ELMAS TESTERE SAN. VE TIC. LTD. ŞTI

Turkey

Our Core drills are manufactured with optimised diamond secment and welded with the latest Laser welding technology

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Core Drills

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Drilling Machines Hydraulic Core Drills Hydraulic Earth Augers Hydraulic Mounted Earth Augers Hydraulic Ground Drivers Hydraulic Post Drivers Brochure Drilling Machines Screw Drivers Hammer Drills Impact Wrenchs Hydraulic Hammer Drills Hydraulic Sinker Drills Hydraulic Impact Wrenches Hydraulic Angle Drilling Machine Valve Opener Hydraulic Post Puller Hydraulic Self Driving Drilling and Pile-Driving Machines

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Thanks to decades of experience and innovation, the Tyrolit range includes drill bits, including TGD® technology diamond wet drill bits, which fulfil almost all construction requirements. Especially in combination with Tyrolit drill motors, they offer reliable and clean results. Tyrolit fulfils the expectations of construction professionals with durable wet core bits for precise core drilling in various dimensions. — For reinforced concrete, steel, masonry, brick, sand-lime brick, fireclay brick, asphalt and special applications — Holders and connection threads in accordance with local standards for all motor types — Perfect system solutions with Tyrolit drill motors and drill rigs — Special dimensions and customised solutions on request Tyrolit offers vacuum-brazed diamond tile drills for wet and dry drilling (with paraffin), which enable precise drilling without edge chipping in tiles, porcelain stoneware and marble slabs.

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Can be dismantled in three parts so can be used from out of the building without a core drill, i.e. for FTTX, gas connections Pneumatically driven hammer bore head assembly is ideally suited for alternating soils. If the hammer bore head meets with resistance (larger rock inclusions, solid rock, rubble deposits or brickwork), the hammer effect is activated automatically. The complete system with hydraulic power unit and mixing unit MA09 can be placed on a small trailer for safe transportation. Can be dismantled Portable Can be applied from out of a building

Request for a quote

NORELEM FRANCE

France

The connecting sets are used for connecting two aluminium profiles at right angles. The connection is nonrotating. For larger profiles several connecting sets can be mounted on the end for greater strength Low workload. Cut a thread in the end face core hole. Drill a through hole for tightening the screw in the opposing profile.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

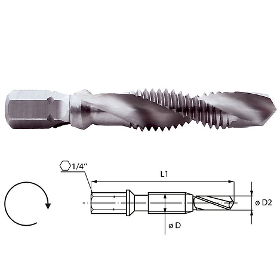

Thread standard: Metric, ISO DIN 13 Type: Combined machine bit tap (core hole drilling and thread tapping) for through holes Application: Combined (core hole drilling and thread tapping) Material of product: HSSG Surface treatment: no For materials: Materials of medium mechanical strength, non ferrous metals and thermoplastics Tensile strength up to: 600 N/mm2 Standard: Factory standard Tolerance: ISO2/6H Combined Bit taps have been designed for drilling, tapping and deburring in one operation using battery-powered screwdriver drills and electric hand drills with right-hand and left-hand rotation, but they are also suitable for thread cutting in a stationary drilling machine. It is possible with this tool to produce through threads up to a maximum threaded depth of 1 x D. They are especially usefull for mounting an dsmall batch production. Take care that the tool and the axis of the hole are exactly aligned and use a suitable cutting oil.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

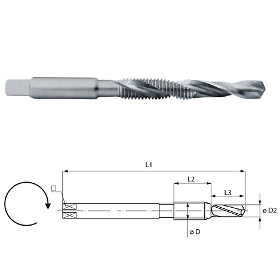

Thread standard: Metric, ISO DIN 13 Type: Combined machine tap (core hole drilling and thread tapping) Application: Combined (core hole drilling and thread tapping) Material of product: HSSE Surface treatment: no For materials: Materials of medium mechanical strength (alloyed and non-alloyed steels up to 600 N/mm², Malleable cast iron, Graphite cast iron, Copper, Brass, Aluminium, Aluminium-magnesium alloys, Zink alloys, Red bronze, Electron metall, Pressure-cast zink) Tensile strength up to: 600 N/mm2 Standard: DIN 357 Tolerance: ISO2/6H Combined machine taps enables the user to produce the tapping drill hole and the through thread in one operation without any tool changing. The tool incorporates a twist drill before the thread-tapping part. It is possible with this tool to produce through threads up to a maximum threaded depth of 2 x D. It is sensible to use this tool on machines possesing an RPM switchover facility for drilling and tapping.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Our high-performance cutting paste in the practical 100ml pack is characterised by particularly high pressure additives that achieve a very high lubrication performance. The paste adheres firmly to the cutting edges and only becomes liquid during use. For optimum results, the cutting paste should be applied undiluted. This cutting paste is ideal for many machining operations such as drilling, thread cutting, thread cutting, milling, core drilling and sawing. It is suitable for all types of steel - from iron and tool steel to high-alloy steels and chrome-nickel alloys to aluminium, titanium, manganese, cast steel, grey cast iron, brass, bronze and all stainless steels V2A, V4A, INOX etc. Due to the environmentally friendly, petroleum-free, chlorine-free and sulphur-free formulation, the high-performance cutting paste not only offers longer tool life, but also leaves no greasy oil film on the workpieces.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

DRILLSTAR fishing magnet is a valuable tool before diamond coring or drilling. Its strong magnetic field will retrieve all types of small steel objects from the bottom of the hole. It is available is a variety of sizes and shapes, to suit the most demanding fishing jobs. Two main designs are available : - Classic design, with a single magnet. - Modular design, using multiple small, high-strength magnets: this design enables a wide range of lifting forces and magnetic surface shapes, using the most powerful magnets available today. Mud ports can be added on the tool bottom or side to clean out the fish. Our magnets are available in two grades, depending on temperature rating : - Normal, up to 300 deg F (150 deg C). - High Temp, up to 570 deg F (300 deg C). Unlike traditional fishing magnets, DRILLSTAR Magnets are permanent and do not require any periodic re-magnetization. High-temp magnets are designed to lose very little force with temperature increase (3% per 100 deg C)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Using TAPTITE 2000® ensures that in metal-joining applications, you can eliminate work processes such as tapping and the use of additional fastening elements. The fastener is screwed straight into a cast or drilled core hole. The polygonal cross-section geometry of the shaft of the screw ensures that the thread is chiplessly formed, so that if a repair is needed it can accept a conventional threaded screw. This provides some significant quality advantages: easy to position the screw low tapping torque high vibration resistance high vibration resistance high pre-load forces high assembly reliability Your commercial benefits: The overall cost of fastenings is reduced by up to 88%.

Request for a quoteResults for

Core drilling - Import exportNumber of results

19 ProductsCompany type