- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- core drilling

Results for

Core drilling - Import export

RHODIUS ABRASIVES GMBH

Germany

Core drill for concrete and high-density limestone. • Can be used with fitting accessories CDS • Extremely long service life • High cutting speed

RHODIUS ABRASIVES GMBH

Germany

Special socket driller with back holes for controlled dust extraction in occupied rooms. Very good cooling of the segments and significant wear reduction due to immediate disposal of waste material. The diamond core drill runs more smoothly and does not jam thanks to less friction at the outer wall. Significantly reduced dust development. • Universal application in old and new constructions • Particularly suitable for indoor applications • Matching extraction 304018

RHODIUS ABRASIVES GMBH

Germany

Matching accessory for CD10 / CD20 core drill. • Matched to core drill

RHODIUS ABRASIVES GMBH

Germany

Tile drill bit for use on angle grinders with an M14 thread. • Cool cut through internal cooling wax • Excellent service life • High cutting speed

RHODIUS ABRASIVES GMBH

Germany

Tile drill bit for use on drills with a ¼” bit adapter. • Cool cut through internal cooling wax • Excellent service life • High cutting speed

Do you sell or make similar products?

Sign up to europages and have your products listed

KW HYDRAULIK GMBH

Germany

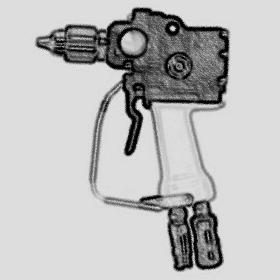

Hydraulic Drilling Machines Hydraulic Core Drills Hydraulic Earth Augers Hydraulic Mounted Earth Augers Hydraulic Ground Drivers Hydraulic Post Drivers Brochure Drilling Machines Screw Drivers Hammer Drills Impact Wrenchs Hydraulic Hammer Drills Hydraulic Sinker Drills Hydraulic Impact Wrenches Hydraulic Angle Drilling Machine Valve Opener Hydraulic Post Puller Hydraulic Self Driving Drilling and Pile-Driving Machines

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Can be dismantled in three parts so can be used from out of the building without a core drill, i.e. for FTTX, gas connections Pneumatically driven hammer bore head assembly is ideally suited for alternating soils. If the hammer bore head meets with resistance (larger rock inclusions, solid rock, rubble deposits or brickwork), the hammer effect is activated automatically. The complete system with hydraulic power unit and mixing unit MA09 can be placed on a small trailer for safe transportation. Can be dismantled Portable Can be applied from out of a building

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Using TAPTITE 2000® ensures that in metal-joining applications, you can eliminate work processes such as tapping and the use of additional fastening elements. The fastener is screwed straight into a cast or drilled core hole. The polygonal cross-section geometry of the shaft of the screw ensures that the thread is chiplessly formed, so that if a repair is needed it can accept a conventional threaded screw. This provides some significant quality advantages: easy to position the screw low tapping torque high vibration resistance high vibration resistance high pre-load forces high assembly reliability Your commercial benefits: The overall cost of fastenings is reduced by up to 88%.

Request for a quoteResults for

Core drilling - Import exportNumber of results

9 ProductsCountries

Company type