- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tools

Results for

Tools - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Inch sized UNF helicoidal thread inserts in stainless steel (helicoils) with screw lock Reinforce the thread in low shear strength materials, such as aluminum, aluminum alloys, etc. The self-locking thread insert is identical in construction and operating principle to the regular helical thread insert, but it also offers a braking action on the screw thanks to the particular polygonal configuration of one or more turns of the insert thread. In this way, the screw remains tightened with absolute reliability even in the presence of vibrations or shocks. The anti-unscrewing braking action remains even after numerous screwing and unscrewing operations The self-locking thread allows you to eliminate the use of other locking elements, such as elastic washers or similar, remaining effective even in the presence of high temperatures For installation you may use taps and tools available in this sections: Thread insert taps, Installation tools for thread inserts Made in the EU.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Type H Helicoil HSSE tap for inch sized UNC thread inserts. Compatible with all types of helicoidal thread inserts For blind holes and manual or machine use. Spiral flutes of the tap extract chips from blind holes which allows to avoid stuffing Complies with DIN 81402 For better results, you may first use a roughing tap to prepare a hole Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and self-tapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The Candle Thread repair kit contains long version of finishing thread insert tap, installation tool and thread inserts (see attached data sheet). All contained in a practical plastic case, easy to store and transport. For use in car and motorcycle engines Our thread repair kit is one of the most professional helicoil kits on the market. The installation tool is equipped with a threaded nose to prepare the helicoil thread insert to the size of the thread, making installation simple and safe Excellent choice for repairing damaged, span and worn threads in steel, iron, aluminum, alluminium alloys and hard plastic materials Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

A single-thread galvanized steel self-tapping screw with a 30-degree angle. Countersunk head Standard Pozidriv-type cross impression (Torx impression is also available upon request) Reduced core and wide thread pitch for high performance in plastic materials Specially designed to provide reliable fastenings in a wide variety of thermoplastic materials, such as ABS, polyamide e.g. Nylon 6-6, PVC and polycarbonate Very simple installation using a regular screwdriver

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

A single-thread galvanized steel self-tapping screw with a trilobal shank and single thread with 45°degree angle Pan head Standard Pozidriv-type cross impression (Torx impression is also available upon request) The special shape of its cross-section, the high ratio of the outer diameter to the diameter of the shank, the large pitch of its thread and the narrow angle at the apex of the 45 degrees threads ensure the best anchorage in plastic materials Better distributed and lower value stresses in plastic materials, highly vibration- and tear-resistant tightening, reduced risk of cracking in materials, screwing with low torque value Specially designed to provide reliable fastenings in a wide variety of thermoplastic materials, such as ABS, polyamide e.g. Nylon 6-6, PVC and polycarbonate Very simple installation using a regular screwdriver

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The flush self-clinching nut is a fully concealed element. Indispensable when you want to have the sheet metal completely smooth, free of protrusions on both sides This self-clinching nut is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch, applyinng only sufficient pressure to squeeze the nut into the parent sheet. The sheet metal experiences plastic deformation and locks the fastener firmly to itself. After installation the hexagon head should be flush with the sheet and the spigot should not protrude through the opposite side. So the result is aesthetically perfect and hexagon head provides high tensile as well as torsional strength The nut can be mounted on already painted or treated sheet metal as it requires no further processing after installation

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

This self-clinching broaching nut for plastic materials is widely used in the electronics industry. It offers a threaded hole of high resistance to both torsion and tensile strength This self-clinching nut is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch. The parent material experiences plastic deformation and locks the fastener firmly to itself Standard material: Electro tin plated steel and stainless steel

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

This self-clinching broaching standoff for plastic materials is widely used in the electronics industry. It offers a threaded hole of high resistance to both torsion and tensile strength and allows panels to be spaced at the desired distance This self-clinching standoff is part of our line of self-clinching inserts. All Clinch inserts are installed using a simple punch During installation process, the fastener is placed in an appropriately sized hole and then compressed by means of a punch. The parent material experiences plastic deformation and locks the fastener firmly to itself Standard material: Electro tin plated steel and stainless steel

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

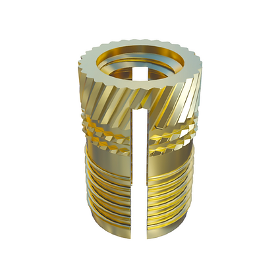

The S10 are self-tapping thread forming inserts to be installed into cylindrical holes Best suited for ductile, softer thermoplastics or thermosets They provide the best pull-out resistance for a post-mold installed inserts Very easy installation, also using a simple screwdriver Symmetrical shape, they do not need to be oriented during installation process, thus can also be easily used in automatic systems Inch versions from 4-40 to 1/4-20 also are available on request

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The THREAD-SERT are self-tapping inserts to be installed into cylindrical holes Suitable for installation in a wide range of thermoplastics and thermosets They are particularly designed for applications that may involve a high tensile load Very easy installation, also using a simple screwdriver Available in two versions with o without head. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. This feature is also useful in applications with electrical contacts Also known as SCREW-SERT, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The EXPANSION-SERT are press-in expansion inserts to be installed into cylindrical holes Suitable for applications in thermoset plastics Due to its diamond knurled design, this insert penetrates for a minimum length within the hole walls without decreasing tensile strength. This feature makes it ideal for applications in hard thermoset plastics They are recomended for applications where high resistance values are not required They are installed by simple pressure, without the need for special equipment Headed (flanged) and reverse-headed (reverse flanged) versions are also available. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. In inverted flange inserts, a screw can be inserted on the opposite side of the flange, offeing very high pull-out resistance Also known as BANC-LOK, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S50, S51 are press-in inserts to be installed into cylindrical holes Suitable for soft thermoplastics The helical knurl of the outer surface is specially designed to facilitate insertion by allowing maximum plastic sliding of the material in the serration grooves They allow easy and low-cost assembly, as no special machinery is required Offer moderate pull-out and good torque resistance They are available in unheaded S50, and headed (flanged) S51 versions. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. In the S51 a screw can be inserted on the opposite side of the flange, allowing to achieve very high pull-out resistance. It also ensures a large contact area, which is useful for electrical contacts and specific applications The S50 in addition are symmetrical so they do not need to be oriented during installation process.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The PRESS-SERT are press-in expansion inserts to be installed into cylindrical holes Suitable for applications in thermoplastic materials The combination of flat and knurled areas ensure high torque and pull out performance normally achievable only with inserts that are installed by a hot/ultrasonic process These inserts are installed by simple pressure, without need for special equipment Also known as PRESS-LOK, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

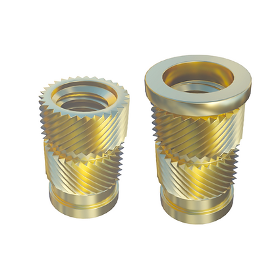

The S14 (Short version) are inserts for plastic with heat/ultrasonic installation into tapered holes with an 8° angle In the short version these inserts offer the advantage of having reduced dimensions, shorter installation times and lower costs. On the other hand, the resistance to torque and pull out loads is reduced comparing to long version Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The tapered form facilitates proper seating and maximizes the surface contact between the insert and hole wall prior to the application of heat or ultrasonic vibration. These inserts are the best choice when using ultrasonic insertion techniques The insert's straight-toothed upper ring and oblique-toothed middle ring provide high torque and pull out resistance, ensuring complete filling of the plastic material in the cavities below Installation must be carried out using heat conduction or ultrasonic machines.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S19, S20 (Long version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes These are the longer versions of the S19, S20 Short inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The S19, S20 inserts are designed with a wide center knurl coupled with two smaller knurls and deep undercuts on both ends to maximize torque and pull out performance They induce very low radial stresses and are therefore particularly recommended in holes with thin walls. In this case the hole must be a bit wider. Optimal size should be determined after appropriate practical tests Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S19, S20 (Short version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes In the short version these inserts offer the advantage of having reduced dimensions, shorter installation times and lower costs. On the other hand, the resistance to torque and pull out loads is reduced comparing to long version Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The S19, S20 inserts are designed with a wide center knurl coupled with two smaller knurls and deep undercuts on both ends to maximize torque and pull out performance They induce very low radial stresses and are therefore particularly recommended in holes with thin walls. In this case the hole must be a bit wider. Optimal size should be determined after appropriate practical tests Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

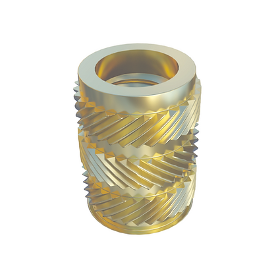

The SONIC-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics They are designed for quick and economical installation Opposing knurls of the insert offer high torque and pull out performance Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Also known as SONIC-LOK, with equivalent shape, features and dimensions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The FLO-SERT are inserts for plastic with installation during plastic molding Suitable for installation in a wide range of thermoplastics and thermosets Blind bottom prevents plastic inflow inside the insert Unique design with three opposite helical knurled bands, combined with hollow parts, provides very high torque and pull out resistance Also known as FLO-TECH, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Hand tap, Form C, for through and blind holes, with straight flutes Application: General use Material of product: HSSG Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 352 Tolerance: ISO2/6H Set of 3 taps (taper, intermediate, finish). Three-piece hand taps- sets are used for regular threads with coarse pitch, as the thread profile area is larger than for fine threads and the force effects on the taps are greater. The advantage of three-piece hand taps is that the respective parts of a set share the cutting power: The taper tap (No. 1) (marked with one ring) removes 65 per cent of the thread profile and the intermediate tap (No. 2) (marked with two rings) removes 85 per cent. Pre-cutting and reworking with the intermediate tap (No. 2) bring the thread into shape. In the last step, the finishing tap (No. 3) is used, which has no ring marking.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: Left-hand Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Left-hand (counter clockwise rotation). Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

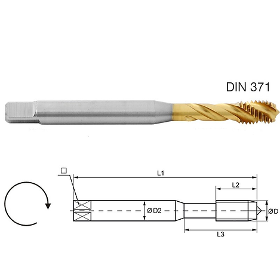

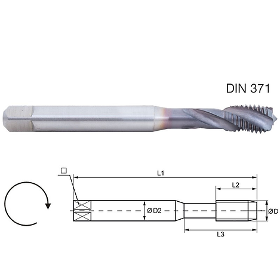

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials Material of product: HSSE Surface treatment: TIN For materials: High-tensile materials, Alloyed heat-treatable steel, Cast iron , Aluminium cast and wrought alloys, Copper and alloys, etc* Tensile strength up to: 1300 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for high-strength material. The TIN surface treatment (titanium-nitride gold-yellow) increases the surface hardness (approx. 2300 HV) and the sliding properties. It provides a better cutting performance and increased tool life time. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: High strength material up to max. 1300 N/mm² Alloyed heat-treatable steel, cast iron with nodular graphite, malleable cast iron Aluminium cast and wrought alloys Si<5% (long-chipping)

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

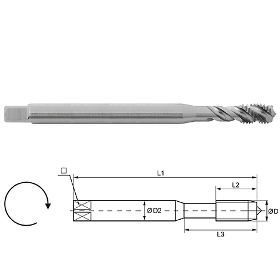

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For stainless steel Material of product: HSSE Surface treatment: VAP For materials: Stainless steels, Copper alloys and copper-zinc alloys etc* Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry and surface treatment for Stainless steel. The oxide surface (vaporized) improves the adhesion of the cutting oil and provides a stabil lubricant film. Cold welding in the tap flanks is reduced. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Materials: Stainless Steels, Inoxable Steels, V2A (AISI 304), V4A (AISI 316), Steels up to 900 N/mm² Copper alloys and copper-zinc alloys (long-chipping) Our taps and dies are produced to the highest quality standards, to ensure precise quality threads.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

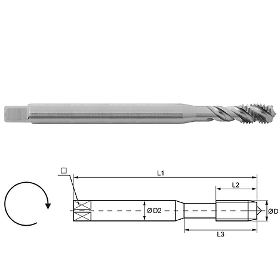

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1400 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. The conical reduced leading thread improves chip drain and reduces thread friction. Tap for machine use in blind holes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

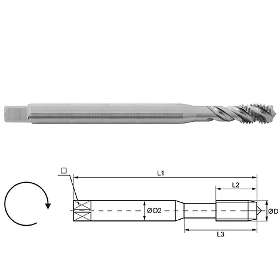

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For long-chipping materials Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Especially for usage on automatic lathes and multi-spindle machines. The 15° spiral flutes make the cutting flanks more stabile. Tap for machine use in blind holes. The fast spiral flutes provide good chip removal from the blind hole. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Overlengthed (long shank) L=100 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Overlengthed (long shank) L=120 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: Overlengthed (long shank) L=150 Material of product: HSSE Surface treatment: no For materials: Unalloyed and low alloyed steel, non abrasive material Tensile strength up to: 900 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

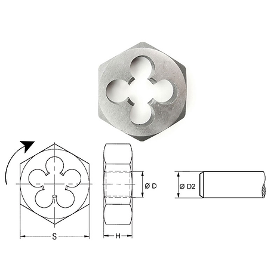

Thread standard: Metric, ISO DIN 13 Type: Hexagon die nut Application: General use Material of product: HSS Spiral entry: no For materials: Non abrasive materials Tensile strength up to: 800 N/mm2 Standard: DIN 382 Tolerance: ISO-6g For repairing and cleaning of damaged threads. For use in awkward places. The hexagon die nut is particularly advantageous for repairs, as it can be moved with ring or open-end spanners, making it easier to reach inaccessible places. Thiscutting tool has an external hexagon and - depending on the size - has three or more cutting edges inside. The holes between the cutting edges take up the chips, roll them and carry them away. Hexagonal die nuts are used to cut screws, nuts and threaded rods in everyday use.Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

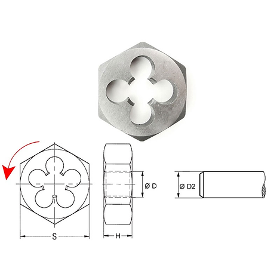

Thread standard: Metric, ISO DIN 13 Type: Hexagon die nut Application: Left-hand Material of product: HSS Spiral entry: no For materials: Non abrasive materials Tensile strength up to: 800 N/mm2 Standard: DIN 382 Tolerance: ISO-6g Left-hand (counter clockwise rotation). For repairing and cleaning of damaged threads. For use in awkward places. The hexagon die nut is particularly advantageous for repairs, as it can be moved with ring or open-end spanners, making it easier to reach inaccessible places. Thiscutting tool has an external hexagon and - depending on the size - has three or more cutting edges inside. The holes between the cutting edges take up the chips, roll them and carry them away. Hexagonal die nuts are used to cut screws, nuts and threaded rods in everyday use. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials

Request for a quoteResults for

Tools - Import exportNumber of results

200 ProductsCountries

Company type

Category