- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating

Results for

Heating - Import export

FERPLAST SNC

Italy

Semiautomatic table top sealer with electric pedal and impulse sealing bar (resistance is heated for a few seconds), suitable for closing bags of plastic material heat-sealable. The closing of the sealing bars by pressing the pedal electric with solenoid allows the operator to have both hands free and for increased production, just select the automatic cycle with timed closure. The timers for adjusting the welding and cooling ensure maximum reliability of each type of material. Simple to use, requires no preheating. Maximum thickness. weldable 0.20 mm. (0.40 mm. Overall)

Request for a quote

FERPLAST SNC

Italy

Machine suitable for the closing of bags with height, mm. to 150 mm. 270 and max weight. 3 kg. The welding system with belts PTFE allows for closing of bags made of polyethylene, polypropylene, cellophane, coated paper, laminated aluminum, etc. The temperature is adjustable from 0-250° C. and the feed speed is adjustable from 0 -12 mt. / min.The welding head is adjustable in height and the distance between the welding and the edge of the bag is 10 mm. The machine is equipped with rotary solid ink marker and interchangeable characters (up to 20 characters with a height of 5 mm.), The system works with inked rollers for easy management and is complete with a photocell to do the marking in the desired location. This model is constructed in the standard version, that is, the advancement of the product occurs from right to left.

Request for a quote

FERPLAST SNC

Italy

Impulse sealers MG 621 series, with 620 mm sealing bar and suitable for sealing polyethylene, pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealing bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. There are special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized bar closing. The MG 621 series sealing machines are available with mechanical or motorized closing bars with 3 or 5 mm sealing thickness depending on the model. Also available in stainless steel with mechanical closure of the bars and and 3 mm sealing.

Request for a quote

FERPLAST SNC

Italy

Impulse manual bag sealers machines FPS series are the simplest and most economical series of sealers machines. The model FPS-C is equipped with a cutter for trimming the envelope. This system allows you to pack products with different lengths and then performing the trimming of the bag, leaving no protruding edges and unsightly. This model is only available in sizes 300 and 400 mm. The sealers FPS/FPS-C are suited to a medium-low production and allow the closing of plastic bags without folding, with maximum thickness of 0.15 mm (0.30 mm total). The sealing is by impulse (the resistance heats for a few seconds) and can be adjusted by timer. The sealing cycle is generally 3 seconds and is indicated by an indicator light. These sealers has a sealing width of 2 mm.

Request for a quote

FERPLAST SNC

Italy

FP MY420-A MARKER AUTOMATIC ROTARY TO SOLID INK Automatic rotary marker with picker for hot stamping on paper, plastic, aluminum foil, etc. Use the proven technology of solid ink rollers, ink is activated by heating and allows immediate drying and indelible imprint on all media. The product is placed in a adjustablencharger, the picker picks up individually the object to be printed and the flat belts convey it under the printing roller. The printing position can be adjusted longitudinally to the millimeter by photocell and two timers. The number of pieces to be printed is programmed from the keypad. Uses numbers and letters (see table) can be placed on multiple lines of printing, printing of production date, expiry date, lot number, etc. to preserve the traceability of the product.Particularly suitable for medium / high production in the food industry and wherever you have the need to give dates or lots on cases.

Request for a quote

FERPLAST SNC

Italy

FP MY300-A AUTOMATIC MARKER ROTARY WITH SOLID INK (Complete with device for collecting and stacking printed cards) Automatic rotary marker with picker for hot stamping on paper, plastic, aluminum foil, etc. Use the proven technology of solid ink rollers, ink is activated by heating and drying allows immediate and indelible imprint on all media. The product is placed in a charger adjustable, the picker picks up individually the object to be printed and the flat belts convey it under the printing roller. The printing position can be adjusted to the millimeter by photocell and two timers. The number of pieces to be printed program from the keypad. Use numbers and letters (see table) can be placed on multiple lines of printing, printing of production date, expiry date, lot number, etc. to preserve the traceability of the product.Particularly suitable for medium / high production in the food industry and wherever you have the need to give dates or lots of cases.

Request for a quote

FERPLAST SNC

Italy

FP MY380-F AUTOMATIC ROTARY MARKER WITH SOLID INK ROLLER (Complete with device for gathering and packaging printed labels) Automatic rotary marker with feeder for hot stamping on paper, plastic, aluminum sheets, etc..; Use the proven technology of solid inkrollers, ink is activatedby heating anddrying allow simmediate and indelible impression onall printable products. The productis placed in an adjustable charger, the feeder picks individually the object to be printed and flat belts carry itunder the roller printer. The print position can be adjusted to the millimeter by two photocell and timer. The number of pieces to be printed is programmed from the keypad. Use numbers and letters(see table) for printing production date, expiration date, lot number, etc.. to preserve the traceabilityof the product. Particularly suitable for medium/ high production in the food industry and wherever there is the need to give dates on labels.

Request for a quote

FERPLAST SNC

Italy

CODE MARKER FPHP 280- Recommended for medium-high productions. Thermal marker hot ink ribbon, ideal for marking labels and cartons. Operation: The operator must enter the letters in the type holder, turn on the marker and set the temperature suitable for the operation. The variation of working temperature depends on thickness and typology of product to be marked. The marking can be done when the marker has reached the temperature. Marking with FPHP 280 marker: The operator must enter the letters in the type holder. Pressing the electric pedal, the marker makes marking quickly (in about 2 seconds). It's a recommended marker to print expiration dates or lots. It's an electric model, then the printing quality is very good and does not vary from time to time because the descent of the characters happens in a vertical manner and the pressure is always constant. The head with the letters transfers ink from the ink ribbon to the product creating a permanent and lightly engraved marking.

Request for a quote

FERPLAST SNC

Italy

ME-FDE SEALERS WITH DOUBLE MOTORIZED PULSE SEALING BAR AND TEMPERATURE CONTROL The new bench sealers with double impulse sealing bar and temperature control, allow the optimal sealing of any type of envelopes and sealable bags. The high pressure exerted by the motorized descent of the bars (0.7 Kg./cm2) allows perfect sealing even on very thick materials. The double active motorized sealing bar (heats above and below) and the 5 mm sealing they allow the closure of envelopes with high thickness, laminated and envelopes with bellows. In addition to sealing polyethylene, polypropylene, coupled paper, aluminum, pvc and medical bags, it also allows the sealing of advertising banners. To seal the banners, we recommend sending samples, without obligation, to carry out the sealing tests. Maximum sealable thickness 0.20 mm (0.40 tot). Timers for regulating the sealing and cooling temperature ensure maximum reliability on all types of material.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

High quality heat gun with extensive temperature and airflow control. Two infinitely adjustable air flow rates and a digital display with memory function. Incredibly strong 2000W-motor, which can be quickly reach a temperature of 650°C. The heat gun has an improved thermal safety: the gun will be switched off automatically when the motor overheats. Nominal power consumption: 2000Watt Power supply: 220-240V/50-60Hz Length cable: 2m Working temperature and airflow adjustable in 2 positions: 50 - 650°C Position I: 50°C / airflow 250-500 l/min Position II: 50-650°C / airflow 250-500 l/min 4 mouthpieces included

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

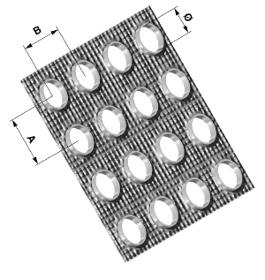

The HEAT-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics Designed for installation in notch-sensitive amorphous thermoplastic materials. The rounded knurling reduces stress on the contact surface while avoiding stress on the material in which it is inserted Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet They are available in unheaded and headed (flanged) versions. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. Also a screw can be inserted on the opposite side of the flange, allowing to achieve very high pull-out resistance. It also ensures a large contact area, which is useful for electrical contacts and specific applications Unheaded inserts in addition are symmetrical so they do not need to be oriented during installation process

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S29, S30 (Long version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes These are the longer versions of the S29, S30 inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates These inserts were designed to provide faster speed and ease of installation, and at the same time maximize torque and pull out performance. The outer profile was made symmetrical with respect to length, so that the insert does not have to be oriented during the installation process. These inserts are therefore suitable for automatic type installations in large volume The S29, S30 offer much higher torque and pull-out resistance than all other inserts Holes sizes are identical to those of the S19 and S20 inserts to provide an easy alternative

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S19, S20 (Long version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes These are the longer versions of the S19, S20 Short inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The S19, S20 inserts are designed with a wide center knurl coupled with two smaller knurls and deep undercuts on both ends to maximize torque and pull out performance They induce very low radial stresses and are therefore particularly recommended in holes with thin walls. In this case the hole must be a bit wider. Optimal size should be determined after appropriate practical tests Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S14 (Short version) are inserts for plastic with heat/ultrasonic installation into tapered holes with an 8° angle In the short version these inserts offer the advantage of having reduced dimensions, shorter installation times and lower costs. On the other hand, the resistance to torque and pull out loads is reduced comparing to long version Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The tapered form facilitates proper seating and maximizes the surface contact between the insert and hole wall prior to the application of heat or ultrasonic vibration. These inserts are the best choice when using ultrasonic insertion techniques The insert's straight-toothed upper ring and oblique-toothed middle ring provide high torque and pull out resistance, ensuring complete filling of the plastic material in the cavities below Installation must be carried out using heat conduction or ultrasonic machines.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S14 (Long version) are inserts for plastic with heat/ultrasonic installation into tapered holes with an 8° angle These are the longer versions of the S14 Short inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The tapered form facilitates proper seating and maximizes the surface contact between the insert and hole wall prior to the application of heat or ultrasonic vibration. These inserts are the best choice when using ultrasonic insertion techniques The insert's straight-toothed upper ring and oblique-toothed middle ring provide high torque and pull out resistance, ensuring complete filling of the plastic material in the cavities below Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Inch version from 2-56 to 5/16-18 is available upon request

Request for a quote

STEFANI SPA

Italy

Our company has been manufacturing finned coil heat exchangers for over 40 years. The design of each finned pack can be totally developed inhouse by Stefani or taken from a drawing supplied by our customer. This is possible thanks to a strategic coengineering service, which is necessary especially when developing specific designs. In the design and manufacture of our finned coil heat exchangers we put all the flexibility and competence that have always been the hallmark of our work. We make customised finned packs for production in batches, dedicated to the machines of our OEM customers and, in general, to data centres, air treatment units for industrial refrigeration, industrial and commercial air conditions and condensing units for refrigeration.

Request for a quote

S.C.E. COMPANY SRL

Italy

The heat exchanger is a component in which an exchange of thermal energy takes place between two fluids at different temperatures. In general, exchangers are open systems that operate without exchange of work, i.e. they present a constant flow of matter and a constant temperature distribution in steady state conditions. For this sector, our company deals with the production and sale of copper and iron pipes which can be semi-finished or assembled suitable for different purposes, including: Sensitive type exchanger, Cooler exchanger, Heater exchanger, Reboiler exchanger, Evaporator exchanger, Condenser exchanger

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STEFANI SPA

Italy

ZONDA is the new Vtype singlerow dry cooler allow heat exchange designed for limited space availability or visibility on the roofs.

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A.’s forging and heattreatment division is capable of forging fittings (in a closed die) up to 4” 16 kg. The heat treatment furnaces and tanks are all certified to Norsok M650 and ASTM A991 standards and can treat any product that M.E.G.A. produces (large and small forgings, pipes and any other type of part).

Request for a quote

SACCHIFICIO VENETO SPA

Italy

We also make bags with HEAT SEALING VALVES to guarantee perfect closure. Furthermore, bags with easy opening on the EASY - OPEN bottom supplied mainly on foreign markets are increasingly in demand.

Request for a quote

CRC PROGETTI SRL

Italy

Heat treatment OPERATING TEMPERATURE: MAX 1200°C Standard power, size and shape or as indicated by the customer. Complete electrical BOXES with CONTROL and SAFETY systems (thermocouples). Stainless steel casing. Room insulation with technical material REFRACTORY and FIBROCERAMIC. Heating by resistive filament* SPIRAL. VIDEO: LINK

Request for a quote

CRC PROGETTI SRL

Italy

Standard power, size and shape or as indicated by the customer. Stainless steel casing. TYPE CERAMIC FIBRE: WORKING TEMPERATURE: MAX 850°C Armour in stainless steel or ALUSI sheets Internal insulation in ceramic fibre. Resistive wire* internal insulating TYPE MICANITE: WORKING TEMPERATURE: MAX 280°C Armour in stainless steel or ALUSI sheets Internal insulation in micanite Resistive wire* internal insulating ARMOURED TYPE: WORKING TEMPERATURE: MAX 700°C Armour in stainless steel Heater*, consisting of a ARMOURED heating element with stainless steel tube. Element development up to 8.00 m. Resistive internal filament* insulated with first choice MAGNESIUM OXIDE.

Request for a quote

DC DI CANDIA RUOTE

Italy

The wheel core of the RXT series is manufactured in special Ditherm® compound, combined with special fibers and molded under an innovative DC developed high pressure + extreme temperature process, and its tyre is made in a special high quality elastic rubber for high temperatures. The white rubber tyre is mechanically bonded to the wheel core, and the coupling is further strengthened by a surface adhesion which is obtained without the use of any glue or vulcanization such as for almost any competition product. This particular bonding is resulting in the highest quality wheel in its range of application, featuring a drastic reduction in the risk of tyre de-bonding during the work in temperatures. They are available with several types of hubs and bearings, in order to allow the perfect response and the best need / price ratio for any type of high or low temperature requirement. The RXT wheels can be fitted into a specific series of brackets for high/low temperatures.

Request for a quote

DC DI CANDIA RUOTE

Italy

The wheel core of the RHT series is manufactured in special Ditherm® compound, combined with special fibers and molded under an innovative DC developed high pressure + extreme temperature process, and its tyre is made in a special high quality elastic rubber for high temperatures. The black rubber tyre is mechanically bonded to the wheel core, and the coupling is further strengthened by a surface adhesion which is obtained without the use of any glue or vulcanization such as for almost any competition product. This particular bonding is resulting in the highest quality wheel in its range of application, featuring a drastic reduction in the risk of tyre de-bonding during the work in temperatures. They are available with several types of hubs and bearings, in order to allow the perfect response and the best need / price ratio for any type of high or low temperature requirement.The RHT wheels can be fitted into a specific series of brackets for high/low temperatures.

Request for a quote

DC DI CANDIA RUOTE

Italy

The XTW series is the only wheel which is assuring a temperature resistance up to +400°C and not being made out of aluminum or cast-iron, with the big advantage to preserve the floor and to secure a dramatic reduction of noise if compared to metal wheels.They are available with several types of hubs and bearings, in order to allow the perfect response and the best need / price ratio for any type of high or low temperature requirement. The XTW wheels can be fitted into a specific series of brackets for high/low temperatures, which are specifically studied and produced to fulfill the extremely wide variability of conditions to which they are submitted in the world of uses in temperatures and bakery / food industry. Brackets are fully certified and manufactured with food and sanitary grade Stainless Steel in AISI 304 / 316, and are available in both metric and inches standard sizes, and are also available in double-layer galvanized pressed steel. They are RoHS - REACh compliant.

Request for a quote

DC DI CANDIA RUOTE

Italy

The STW series wheels are manufactured with an exclusive DC Di Candia Ruote’s composite material, the THT, which has been studied and developed in our plant in Besnate, and is used exclusively for the production of this wheel range. These wheels grants a superior and unmatched mechanical resistance to heavy impacts, an outstanding resistance against chipping and breaking caused by hitting of sharp obstacle and a great rolling capacity even in plain bore configuration, thanks to the self-lubricating properties of the THT material. They also assure an incredible resistance against aggressive cleaners, chemicals, oils, acids, steam and salty water, and are available with plain bore and with double special HT ball bearings, to allow a perfect rolling capacity in any condition of use. The THT material is certified by FDA for contact with foods. The STW wheels can be fitted into a specific series of brackets for high/low temperatures, which are specifically studied and produced.

Request for a quote

CADALPE SRL

Italy

The Helicoid monotube heat exchanger, operating by means of counterflowing cooling or heating fluids, has an exceptionally high heat exchange coefficient, due to the special corrugated profile of the two concentric stainless steel pipes. This considerably reduces the exchange surface compared with conventional smooth pipe heat exchangers. A wide range of original applications are available. This is the only tubular heat exchanger for the homogeneous cooling or heating of grape mash (with or without stalks), fruit pulp and other products containing suspended solids or fibres (up to 25-30%). It is therefore ideal for: • in-line chilling of white grape mash at 15°C, to prevent fermentation before pressing • instantaneous chilling of black grape mash at 25°C • black grape mash fermentation control by means of by-pass circulation. Made entirely in AISI 304 stainless steel Supplied on request with effective insulation by injected expanded polyurethane and a stainless steel cover

Request for a quote

SEIT ELETTRONICA SRL

Italy

IMPROVE YOUR HEATING PROCESS PLATINUM MF Series is the new range of Medium-Low Frequency Induction Generators, ideal for all heating automatic or manual processes. With the MF generators, you have a total control of the heating process and you get high quality results. MF generators guarantee you repetitiveness and precision in reduced time. CHARACTERISTIC Model: Platinum MF5 - 10 - 15 - 25 Output power (kW): 5kW - 10kW - 15kW - 25kW Duty Cycle: 100% Frequency range: 15 kHz -55 kHz Output power regulation: 10 - 100% Power supply: 400V - 3ph - 50/60Hz Cooling: H2O demineralized FEATURES - Touch-screen display 7” - Digital control of all functions - Creation and saving of multistep programs - Heating profiles based on temperature and / or power - USB connection - Multilingual user interface

Request for a quote

SEIT ELETTRONICA SRL

Italy

IMPROVE YOUR HEATING PROCESS PLATINUM HF Series is the new series of high frequency induction generators, suitable for manual and /or automatic heating of medium-small parts. Ideal for fast and controlled heating processes, such as annealing and hardening. Thanks to their versatile characteristics and smart design, the PLATINUM generators are recommended for manual use as well as integration in automatic processes. CHARACTERISTIC Model: Platinum HF Output power (kW): 2.5kW /3kW / 6kW Duty Cycle: 50% / 100 % Frequency range: 200 kHz -600 kHz Output power regulation: 10 - 100% Power supply: 230V - 1ph - 50/60Hz Cooling: H2O demineralized FEATURES - Touch-screen display 7” - Digital control of all functions - Creation and saving of multistep programs - Heating profiles based on temperature and / or power - USB connection - Multilingual user interface

Request for a quoteResults for

Heating - Import exportNumber of results

35 ProductsCountries

Company type

Category

- Tools & Hardware (6)

- Package sealing machinery (5)

- Heat exchangers (4)

- Induction heating systems (4)

- Heat transfer printing (4)

- Wheels, castors and rollers (4)

- Welding, soldering and brazing - equipment and supplies (3)

- Bakery - machinery and equipment (3)

- Brazing - equipment and supplies (3)

- Heating and air conditioning - works (2)

- Pipes and tubes, copper (2)

- Heating, industrial - installations and equipment (1)

- Heat treatment furnaces (1)

- Heat treatment of steels and metals (1)