- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating

Results for

Heating - Import export

STEFANI SPA

Italy

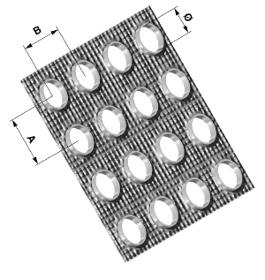

Our company has been manufacturing finned coil heat exchangers for over 40 years. The design of each finned pack can be totally developed inhouse by Stefani or taken from a drawing supplied by our customer. This is possible thanks to a strategic coengineering service, which is necessary especially when developing specific designs. In the design and manufacture of our finned coil heat exchangers we put all the flexibility and competence that have always been the hallmark of our work. We make customised finned packs for production in batches, dedicated to the machines of our OEM customers and, in general, to data centres, air treatment units for industrial refrigeration, industrial and commercial air conditions and condensing units for refrigeration.

Request for a quote

STEFANI SPA

Italy

ZONDA is the new Vtype singlerow dry cooler allow heat exchange designed for limited space availability or visibility on the roofs.

Request for a quote

SACCHIFICIO VENETO SPA

Italy

We also make bags with HEAT SEALING VALVES to guarantee perfect closure. Furthermore, bags with easy opening on the EASY - OPEN bottom supplied mainly on foreign markets are increasingly in demand.

Request for a quote

CADALPE SRL

Italy

The Helicoid monotube heat exchanger, operating by means of counterflowing cooling or heating fluids, has an exceptionally high heat exchange coefficient, due to the special corrugated profile of the two concentric stainless steel pipes. This considerably reduces the exchange surface compared with conventional smooth pipe heat exchangers. A wide range of original applications are available. This is the only tubular heat exchanger for the homogeneous cooling or heating of grape mash (with or without stalks), fruit pulp and other products containing suspended solids or fibres (up to 25-30%). It is therefore ideal for: • in-line chilling of white grape mash at 15°C, to prevent fermentation before pressing • instantaneous chilling of black grape mash at 25°C • black grape mash fermentation control by means of by-pass circulation. Made entirely in AISI 304 stainless steel Supplied on request with effective insulation by injected expanded polyurethane and a stainless steel cover

Request for a quote

SEIT ELETTRONICA SRL

Italy

IMPROVE YOUR HEATING PROCESS PLATINUM MF Series is the new range of Medium-Low Frequency Induction Generators, ideal for all heating automatic or manual processes. With the MF generators, you have a total control of the heating process and you get high quality results. MF generators guarantee you repetitiveness and precision in reduced time. CHARACTERISTIC Model: Platinum MF5 - 10 - 15 - 25 Output power (kW): 5kW - 10kW - 15kW - 25kW Duty Cycle: 100% Frequency range: 15 kHz -55 kHz Output power regulation: 10 - 100% Power supply: 400V - 3ph - 50/60Hz Cooling: H2O demineralized FEATURES - Touch-screen display 7” - Digital control of all functions - Creation and saving of multistep programs - Heating profiles based on temperature and / or power - USB connection - Multilingual user interface

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SEIT ELETTRONICA SRL

Italy

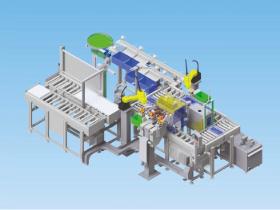

Platinum HUB is a scalable platform you can customize according to your brazing process. You can set up the layout adding multiple stations to: flux, apply brazing paste or pre-formed brazing alloy, wash, dry and cool the parts you are processing, mark with galvo laser technology, and automatic loading and unloading the line using co-bot or industrial robots. This system will for sure adapt to your process and needs and will give you the chance to expand it and add new functions when you really need it. You can use all models of the Platinum series ranging from 2,5KW HF to 25KW MF. The intuitive control system perfectly fits with Seit Elettronica software philosophy: “We provide innovative industrial products with a simple and modern user interface.” These characteristics are pairing and expanding all the new functionalities of “Platinum App” to collect, compare, store and control all the key data from your production as cycle time, temperature and more.

Request for a quote

SEIT ELETTRONICA SRL

Italy

Platinum TT is the evolution of the modern induction brazing, this platform can be set up with 4 different stations to: flux, apply brazing paste, cool the parts, mark with galvo laser technology. This system will for sure adapt to all your process and needs. You can use all models of the Platinum series ranging from 2,5KW HF to 25KW MF. The intuitive control system perfectly fit with Seit Elettronica software philosophy: “We provide innovative industrial products with a simple and modern user interface.” These characteristics are pairing and expanding all the new functionalities of “Platinum App” to collect, compare, store and control all the keys datas from Your production cycle time and more.

Request for a quoteResults for

Heating - Import exportNumber of results

8 ProductsCountries

Company type