- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- zinc coating

Results for

Zinc coating - Import export

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Touching-up damaged points on galvanised surfaces, for example after welding, drilling or cutting processes Priming of ferrous metals when zinc galvanising cannot be carried out. For example, in vehicle and ship repairs, in steel building construction, civil engineering and bridge building, in tank and overhead line construction, on grids, fence and traffic signal posts, exhaust systems, drain gutters Also suitable for spot welding thanks to the good electrical conductivity Advantages and benefits Highly effective due to active, cathodic corrosion protection Versatile use as durable corrosion protection at thermally stressed metal parts Highly economical due to low consumption and self-cleaning spray valve Supplements galvanising and forms a rough adhesive surface for subsequent painting

Request for a quote

RUDOLF GUTBROD GMBH

Germany

In order to be able to benefit from the excellent strength values of carbon steels in a heavily corrosive environment – in comparison with expensive stainless steels – Zinc Lamella Coating can be used. Our Zinc Lamella Coating generates the so-called cathodic protection. The more ignoble zinc “sacrifices” itself to protect the base material. Steel can be protected in this way. The layer thickness is between 10 μm and 25 μm, for specific requirements thicker layers are possible. For metric threated parts it is necessary to meet the tolerances according to ISO 965, to avoid the screw thread‘s agglutination and to keep the friction coefficients accordingly adjustable. In contrast to paints, where the danger infiltration is given, this phenomenon is prevented through the „sacrificing“ impact of zinc. In salt spray tests zinc lamella coatings achieve better results than typical galvanic zinc plating, which often only reaches 96 h to 200 h in salt spraying tests (usually according...

Request for a quote

BÜRKLE GMBH

Germany

Easy-Click closure - stop-it can be opened and closed in any position - without tiresome screwing on and off. High quality material - stop-it made from the heat resistant and chemical resistant plastic PVDF. The clamp is galvanised steel. The hose clip can be used wherever the flow in hoses with liquids or gases needs to be regulated or stopped. Stepless flow regulation: With the hose clip stop-it's knurled screw, a stepless, delicate flow regulation or complete stop of the flow are possible, even for existing hose connections. The hose is compressed over a wide area against the sturdy steel hook in order to prevent it from being damaged.

Request for a quote

C+R HYDRAULICS GMBH

Germany

DC 01 - DC 04 electrolytically galvanised DC01+ZE25/25 A-PC senzimir galvanised DX51D+Z275-MA-C aluminium-zinc coated zinc-aluminium coated

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

MBW GRUPPE

Germany

"The alkaline zinc-iron alloy coating is very commonly applied to steel and ferrous materials. It has been used successfully for many years in the automotive and electrical industries, in equipment and mechanical engineering and also in sheet metal processing. It is characterised by a higher resistance to environmental influences. In addition to the classic galvanising process, the zinc-iron process provides a high degree of corrosion protection paired with an attractive surface design (black, silver), as well as uniform coating thickness distribution. This is a crucial advantage for workpieces with fit sizes. This process is suitable for both barrel and rack goods."

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

In addition to the product range of classic cold rolling mills, we can also offer our customers electrolytically galvanized strip. The zinc coating offers excellent corrosion protection: In cooperation with our customers, we have developed a product that solves the problem of zinc abrasion in the processing of galvanized strips - ZPL (Zinc Plus Paint). An organic coating system is applied immediately after electrolytic galvanizing. This results in a colourless, uniform, highly lubricious layer with a dry film thickness of 0.50 - 3.00 µm, which can of course also be supplied in any desired colour. ZPL offers the following advantages: Further improvement of corrosion protection Excellent sliding properties, preventing zinc abrasion in the tool Reduced tool wear Longer tool life Oil-free processing is made possible Coating and printable layer with "Anti Finger Print" properties

Request for a quote

SIKO GMBH

Germany

Robust and economic plastic handwheel. Various sizes. Hub made of zinc-coated steel for high stability and easy shaft mounting. Various hub versions. With thread for mounting a turning handle (see accessories).

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting*nickel plated*vinyl coated handles*width of mouth 59 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting, nickel plated*vinyl coated jaws*capacity 0 – 40 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting, nickel plated*vinyl coated jaws*capacity 0 – 40 mm

Request for a quote

TOX-DÜBEL-TECHNIK GMBH

Germany

Features • Tension- and pressure-resistant fastening • No backing or wedging of the frame necessary • Corrosion protection due to aluminium-zinc coating • Fire resistant to DIN 4102 (class A1) Description & Area of Application • Galvanized metal frame wall plug, pre-assembled with metric countersunk screw M6 (driver PZ3) • Fire resistant to DIN 4102 (class A1) • Tension- and pressure-resistant fastening • Tightening the screw pulls the cone into the sleeve and spreads it open

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER synchronizing pulleys can be made of such different materials as aluminum, steel, stainless steel, gray cast iron or plastics. The fact that they can be produced with all pitches and designed according to your specifications and drawings ensures an optimal solution for any application. Our synchronizing pulleys work together optimally with our extensive and complete range of timing belts. Together they are a perfectly matched system for your application. We have a large range of standard pulleys on stock, which can be reworked according to your specifications. Special surface coatings, such as hard coating, anodizing, zinc coating, bronzing, improve the corrosion and wear resistance.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

Turned parts, CNC turned parts, long turned parts Part diameter: 0.3 to 200 mm Parts Length: 1000 mm Materials: steel, stainless steel, brass, aluminum and plastic In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

Thickness and strength: 0.3 to 100 mm Parts length: to 500 mm Materials: steel, stainless steel, aluminum and plastic In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER synchronizing toothed shafts can be made of such diff erent materials as aluminum, steel or stainless steel. The fact that they can be produced with all pitches and designed according to your specifications and drawing ensures optimal solutions for all applications and any loads. Our synchronizing toothed shafts work together optimally with our extensive and complete range of timing belts. Together they are a perfectly matched system for your application. We have a large range of standard pulleys on stock, which can be reworked according to your specifi cations within a short time (e.g. bores and machining based on your drawings). Special surface coatings, e.g. such as hard coating, anodizing, zinc coating or bronzing, improve corrosion and wear resistance.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

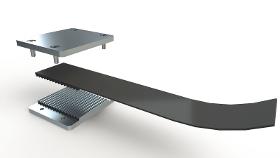

KEIPER timing belt clamping plates can be made of many different materials, e.g. aluminum, steel or stainless steel. Keiper can produce them in all pitches and designed according to your specifications and drawings. This means that you will receive the optimal solution for the intended application and load. Our timing belt clamping plates work together optimally with our extensive and complete range of timing belts: in other words, a perfectly matched system for your requirements. We also have a large number of standard aluminum clamping plates on stock, which can be reworked according to your specifications (e.g. bores and mechanical processing based on drawings). Furthermore, such special surface coatings as hard coating, anodizing, zinc coating or bronzing improve the corrosion and wear resistance.

Request for a quote

SPIROL

Germany

In addition to SPIROL Standard Metric Slotted Spring Pins, SPIROL offers a line of ISO 8752 Slotted Pins to meet market demand for these pins. SPIROL offers Slotted Spring Pins manufactured to the ISO 8752 specification in diameters ranging from 2mm to 12mm in both high carbon steel and austenitic stainless steel in plain finish. ISO 8752 Slotted Pins are not available with supplemental coatings such as zinc plating or passivation due to their propensity to interlock during the finishing process.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

SPLINT-PIN BOLTS, HEAD BOLTS: DIN 1433 (without head) DIN 1434 (with head) DIN 1435 (with head) DIN 1436 (with head) DIN 1443 ISO 2340 (without head) DIN 1444 ISO 2341 (with head) All bolts based on DIN / EN / ISO or by drawing (modified standard) bolt clevis pin DIN 1445 Material: Machining steel e.g. 9SMn(Pb)28k, 11SMn(Pb)30+C... Carbon Steel e.g. C15, C35, C45... Stainless Steel e.g. 1.4305, 1.4301, 1.4571, 1.4104... Aluminum e.g. AlMgPb, AlMgSi0,5, AlMgSi1... In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

STUD BOLTS THREADED BOLTS CLEVIS PINS DIN 1438 DIN 1445 SPLINT-PIN BOLTS, HEAD BOLTS: DIN 1433 (without head) DIN 1434 (with head) DIN 1435 (with head) DIN 1436 (with head) DIN 1443 ISO 2340 (without head) DIN 1444 ISO 2341 (with head) All bolts based on DIN / EN / ISO or by drawing (modified standard) bolt clevis pin DIN 1445 Material: Machining steel e.g. 9SMn(Pb)28k, 11SMn(Pb)30+C... Carbon Steel e.g. C15, C35, C45... Stainless Steel e.g. 1.4305, 1.4301, 1.4571, 1.4104... Aluminum e.g. AlMgPb, AlMgSi0,5, AlMgSi1... In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

STUD BOLTS THREADED BOLTS CLEVIS PINS DIN 1438 DIN 1445 SPLINT-PIN BOLTS, HEAD BOLTS: DIN 1433 (without head) DIN 1434 (with head) DIN 1435 (with head) DIN 1436 (with head) DIN 1443 ISO 2340 (without head) DIN 1444 ISO 2341 (with head) All bolts based on DIN / EN / ISO or by drawing (modified standard) bolt clevis pin DIN 1445 Material: Machining steel e.g. 9SMn(Pb)28k, 11SMn(Pb)30+C... Carbon Steel e.g. C15, C35, C45... Stainless Steel e.g. 1.4305, 1.4301, 1.4571, 1.4104... Aluminum e.g. AlMgPb, AlMgSi0,5, AlMgSi1... In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc.

Request for a quote

SPIROL

Germany

Disc Springs are conically-shaped precision components designed to be axially loaded. Disc Springs are often incorrectly referred to as belleville disc springs, belleville springs, belleville washers or simply conical washers. SPIROL offers the full range of DIN EN 16983 (formerly DIN 2093) Group 1 and 2 Disc Springs in Series A, B, and C. In addition to the DIN specified sizes, SPIROL stocks its own standard sizes with outside diameters ranging from Ø8mm to Ø200mm. SPIROL Standard Disc Springs were designed around the standardized calculations of DIN EN 16984 (formerly DIN 2092), and meet all material, dimensional tolerance, and quality specifications as laid out in DIN EN 16983 (formerly DIN 2093) yet offer an expansion in the diameter and thickness combinations that are not included in the DIN standard. Standard materials include carbon steel and alloy steel, both finished with a protective coating of zinc phosphate and oil.

Request for a quote

WDM DEUTENBERG GMBH

Germany

Gabion meshes from WDM Deutenberg guarantee the required stability and long-lasting – ensured by traceable salt spray tests and a minimum zinc coating of 275 g/m² for galvanized mesh.

Request for a quote

FATH GMBH

Germany

To fasten components to profiles, brakes the anodized coat of the profile - thus ensuring a safe, electrically conductive connection Material: — Steel — Stainless steel — Plastic PA Measures: Thread: M4 - M8 length hammer screw: 16-60 mm many different versions in lengths and widths in the delivery assortment individual designs on request extras: Rotation aid: polyamide spot coating on request surface: with dry sliding film, zinc-nickel or zinc-flake coating on request Note: Matching flange nut available

Request for a quote

FATH GMBH

Germany

Connector plates, for connecting aluminium profile Different sizes and versions: — 20/40; 20/80; 40/40; 40/80; 40/160; 80/80; 80/160; 120/120; 160/160 — 30/60; 30/120; 60/60; 60/120 — 45/90; 45/180; 90/90; 90/180; 180/180 — 135/135 — 38/76-1.5/3"; 38/152-1.5/5.98" — 76/76-3/3"; 76/152-3/5.98"; 152/152-5.98/5.98" — 114/114-4.4/4.4" Material selection: — Anodized aluminium — steel zink plated — Steel black powder coated or blue zinc plated Other surfaces , other colors on request! Translated with www.DeepL.com/Translator (free version)

Request for a quote

STRONG MAGNETS GMBH

Germany

1. A deep cylindrical permanent magnet assembled concentrically in a mild steel pot with spacer of Aluminum or Copper. 2. These magnets are primarily for gripping applications. 3. Magnet material used is Alnico 5, working temperature is up to 250 ° C. North polarity in center of holding face and each magnet has a coated keeper 4. Outer surface except pole can be red (smooth or wrinkle) painted, or coated with Zinc, Nickel or Chrome We have accumulated abundant experience and established stable and credible business relationships with customers worldwide. With rich experience in dealing with all types of large and small orders, we have developed extensive contacts with many local and international freight organizations. Consequently, we are able to ship our goods safely and reliably to almost anywhere in the world

Request for a quoteResults for

Zinc coating - Import exportNumber of results

41 ProductsCountries

Company type

Category

- Locks, bolts and keys (4)

- Turning - steels and metals (4)

- Conveyor belts (3)

- Screw cutting - steels and metals (3)

- Automation - systems and equipment (2)

- Clamp collars, plastic (2)

- Heating, domestic - installations and equipment (2)

- Milling - steels and metals (1)

- Fasteners, metal (1)

- Magnets (1)

- Anti-corrosion coatings (1)

- Dustbins, waste bins (1)

- Fastening devices (1)

- Gratings, metal (1)

- Laboratory equipment and instruments (1)

- Nuts and bolts (1)

- Scissors for household and professional use (1)

- Seals (1)

- Seals - custom packaging (1)

- Silicones (1)