- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- zinc coating

Results for

Zinc coating - Import export

RUDOLF GUTBROD GMBH

Germany

In order to be able to benefit from the excellent strength values of carbon steels in a heavily corrosive environment – in comparison with expensive stainless steels – Zinc Lamella Coating can be used. Our Zinc Lamella Coating generates the so-called cathodic protection. The more ignoble zinc “sacrifices” itself to protect the base material. Steel can be protected in this way. The layer thickness is between 10 μm and 25 μm, for specific requirements thicker layers are possible. For metric threated parts it is necessary to meet the tolerances according to ISO 965, to avoid the screw thread‘s agglutination and to keep the friction coefficients accordingly adjustable. In contrast to paints, where the danger infiltration is given, this phenomenon is prevented through the „sacrificing“ impact of zinc. In salt spray tests zinc lamella coatings achieve better results than typical galvanic zinc plating, which often only reaches 96 h to 200 h in salt spraying tests (usually according...

Request for a quote

BÜRKLE GMBH

Germany

Easy-Click closure - stop-it can be opened and closed in any position - without tiresome screwing on and off. High quality material - stop-it made from the heat resistant and chemical resistant plastic PVDF. The clamp is galvanised steel. The hose clip can be used wherever the flow in hoses with liquids or gases needs to be regulated or stopped. Stepless flow regulation: With the hose clip stop-it's knurled screw, a stepless, delicate flow regulation or complete stop of the flow are possible, even for existing hose connections. The hose is compressed over a wide area against the sturdy steel hook in order to prevent it from being damaged.

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

SIKO GMBH

Germany

Robust and economic plastic handwheel. Various sizes. Hub made of zinc-coated steel for high stability and easy shaft mounting. Various hub versions. With thread for mounting a turning handle (see accessories).

Request for a quote

TOX-DÜBEL-TECHNIK GMBH

Germany

Features • Tension- and pressure-resistant fastening • No backing or wedging of the frame necessary • Corrosion protection due to aluminium-zinc coating • Fire resistant to DIN 4102 (class A1) Description & Area of Application • Galvanized metal frame wall plug, pre-assembled with metric countersunk screw M6 (driver PZ3) • Fire resistant to DIN 4102 (class A1) • Tension- and pressure-resistant fastening • Tightening the screw pulls the cone into the sleeve and spreads it open

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER synchronizing pulleys can be made of such different materials as aluminum, steel, stainless steel, gray cast iron or plastics. The fact that they can be produced with all pitches and designed according to your specifications and drawings ensures an optimal solution for any application. Our synchronizing pulleys work together optimally with our extensive and complete range of timing belts. Together they are a perfectly matched system for your application. We have a large range of standard pulleys on stock, which can be reworked according to your specifications. Special surface coatings, such as hard coating, anodizing, zinc coating, bronzing, improve the corrosion and wear resistance.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER synchronizing toothed shafts can be made of such diff erent materials as aluminum, steel or stainless steel. The fact that they can be produced with all pitches and designed according to your specifications and drawing ensures optimal solutions for all applications and any loads. Our synchronizing toothed shafts work together optimally with our extensive and complete range of timing belts. Together they are a perfectly matched system for your application. We have a large range of standard pulleys on stock, which can be reworked according to your specifi cations within a short time (e.g. bores and machining based on your drawings). Special surface coatings, e.g. such as hard coating, anodizing, zinc coating or bronzing, improve corrosion and wear resistance.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

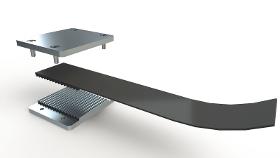

KEIPER timing belt clamping plates can be made of many different materials, e.g. aluminum, steel or stainless steel. Keiper can produce them in all pitches and designed according to your specifications and drawings. This means that you will receive the optimal solution for the intended application and load. Our timing belt clamping plates work together optimally with our extensive and complete range of timing belts: in other words, a perfectly matched system for your requirements. We also have a large number of standard aluminum clamping plates on stock, which can be reworked according to your specifications (e.g. bores and mechanical processing based on drawings). Furthermore, such special surface coatings as hard coating, anodizing, zinc coating or bronzing improve the corrosion and wear resistance.

Request for a quote

SEPA EUROPE GMBH

Germany

SEPA EUROPE, the experts for customized cooling solutions meets the highest expectations with its wide range of guards for axial fans. Modern high-performance fans operate at high speeds which increase the risk of injury. To enhance safety, SEPA EUROPE offers guards for axial fans in every required dimension. The well-designed guards of SEPA EUROPE are not only extremely stable but also improve the appearance of each fan. The high-quality surface (chrome-plated, powder-coated, zinc-plated or pure stainless steel V2A or V4A) stands for a longer service life and extensive protection against corrosion. We perfect the product with excellent finishing and a flawless surface without sharp edges. Additional advantage: The guards of SEPA EUROPE are aerodynamically optimized so that the fans can operate with optimum efficiency. A further advantage is the simple mounting by screwing to the fan.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Base surfaces Standard surfaces can be applied at our in-house electro-plating unit. We also make use of a network of outstanding industry partners able to apply the best surface for every application. Zinc-galvanised with various passivations (CrVI-free) Zinc-nickel-galvanised with various passivations (CrVI-free) Zinc flake coatings for various standard product families Phosphate coatings Further base surfaces on request Topcoats ARNOLD UMFORMTECHNIK GmbH & Co. supplies various organic and inorganic topcoats, seals and low-friction coatings. The appropriate products for the galvanised surfaces or zinc flake coatings can be selected from very many options in the range. Low-friction coatings Seals Seals with integral lubricant Organic and inorganic coatings (different colours on request) The low-friction coatings meet the VDA 235-104 friction coefficient requirements – total µ of 0.09 to 0.14. Further friction value ranges can be adapted on request.

Request for a quoteResults for

Zinc coating - Import exportNumber of results

14 ProductsCompany type