- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- zinc coating

Results for

Zinc coating - Import export

ROKVELAS, UAB

Lithuania

At given need our experts can invoke extensive subcontracting.

Request for a quote

POMPES JAPY

France

Body, cover, rotor, screws and bolts of the body: 316 stainless steel Vanes: PTFE Waterproofing: Teflon-coated braid Handle: zinc-plated steel

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

galvanization electropolishing Zinc nickel coating Manganese phosphate coating chromate and hard chromate coating Cataphoresis coating Powder coating in various RAL colors and more

Request for a quote

MEVATEC S.R.O.

Czech Rep.

Galvanized structure filled with zinc coated sheet metals. Subsequent surface finish with paint RAL 7035. Delivered without stickers andock. Special safety hole for used textile insertion. Height of the insertion hole handle 1250 mm.

Request for a quote

MICRON AMERICA

Turkey

250 pcs of each Oblong ( Oval ) Grommets Includes Teeth Washers. Galvanized steel is a type of steel that has been galvanized by the application of a zinc coating throughout its body so that it can be protected from corrosion or rusting. Galvanized steel has a longer life and durability compared to non galvanized steel.

Request for a quote

MICRON AMERICA

Turkey

250 pcs of each Round Grommet Include Teeth Washers. Galvanized steel is a type of steel that has been galvanized by the application of a zinc coating throughout its body so that it can be protected from corrosion or rusting. Galvanized steel has a longer life and durability compared to non galvanized steel.

Request for a quote

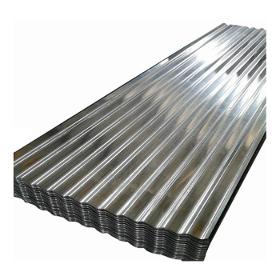

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Standard: AISI, ASTM, BS, DIN, GB, JIS, AS ETC Thickness: 0.12-3.5mm Width:1250/1220/1200/1000/914/762(before corrugation)930/915/910/905/900/880/875/815/810/790/780/680/670/660/655/650(after corrugation) or as required. Ditch and Peak after corrugation: 12 Ditches/11 Peak; 11 Ditches/10 Peak; 9 Ditches/ 8 Peak Length: In coil or as required Zinc Coating: Z40-275g/sqm Paint Top: 15 - 35 Microns Paint Back: 5 - 35 Microns Coating Color: ALL RAL Cards Color Coating Type: Top Painted : PVDF / HDP / SMP / PE / PU Primer Painted : Polyurethane / Epoxy / PE Back Painted : Epoxy / Modified Polyester Coil Weight: 3-8 Tons Coil ID: 508/610mm Color: RAL Code Or According To Customer's Sample Spangle: No spangle, With spangle MOQ: 5 Tons Package: Standard Sea Worthy Package Port: China

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Touching-up damaged points on galvanised surfaces, for example after welding, drilling or cutting processes Priming of ferrous metals when zinc galvanising cannot be carried out. For example, in vehicle and ship repairs, in steel building construction, civil engineering and bridge building, in tank and overhead line construction, on grids, fence and traffic signal posts, exhaust systems, drain gutters Also suitable for spot welding thanks to the good electrical conductivity Advantages and benefits Highly effective due to active, cathodic corrosion protection Versatile use as durable corrosion protection at thermally stressed metal parts Highly economical due to low consumption and self-cleaning spray valve Supplements galvanising and forms a rough adhesive surface for subsequent painting

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC milling. The surface treatment is zinc coating.

Request for a quote

RUDOLF GUTBROD GMBH

Germany

In order to be able to benefit from the excellent strength values of carbon steels in a heavily corrosive environment – in comparison with expensive stainless steels – Zinc Lamella Coating can be used. Our Zinc Lamella Coating generates the so-called cathodic protection. The more ignoble zinc “sacrifices” itself to protect the base material. Steel can be protected in this way. The layer thickness is between 10 μm and 25 μm, for specific requirements thicker layers are possible. For metric threated parts it is necessary to meet the tolerances according to ISO 965, to avoid the screw thread‘s agglutination and to keep the friction coefficients accordingly adjustable. In contrast to paints, where the danger infiltration is given, this phenomenon is prevented through the „sacrificing“ impact of zinc. In salt spray tests zinc lamella coatings achieve better results than typical galvanic zinc plating, which often only reaches 96 h to 200 h in salt spraying tests (usually according...

Request for a quote

BÜRKLE GMBH

Germany

Easy-Click closure - stop-it can be opened and closed in any position - without tiresome screwing on and off. High quality material - stop-it made from the heat resistant and chemical resistant plastic PVDF. The clamp is galvanised steel. The hose clip can be used wherever the flow in hoses with liquids or gases needs to be regulated or stopped. Stepless flow regulation: With the hose clip stop-it's knurled screw, a stepless, delicate flow regulation or complete stop of the flow are possible, even for existing hose connections. The hose is compressed over a wide area against the sturdy steel hook in order to prevent it from being damaged.

Request for a quote

C+R HYDRAULICS GMBH

Germany

DC 01 - DC 04 electrolytically galvanised DC01+ZE25/25 A-PC senzimir galvanised DX51D+Z275-MA-C aluminium-zinc coated zinc-aluminium coated

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

MBW GRUPPE

Germany

"The alkaline zinc-iron alloy coating is very commonly applied to steel and ferrous materials. It has been used successfully for many years in the automotive and electrical industries, in equipment and mechanical engineering and also in sheet metal processing. It is characterised by a higher resistance to environmental influences. In addition to the classic galvanising process, the zinc-iron process provides a high degree of corrosion protection paired with an attractive surface design (black, silver), as well as uniform coating thickness distribution. This is a crucial advantage for workpieces with fit sizes. This process is suitable for both barrel and rack goods."

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

Plate die-cast zinc or stainless steel 1.4305. Anti-slip plate thermoplastic elastomer. Version: Die-cast zinc plate, black powder-coated. Stainless steel plate, bright. Note: Swivel feet consist of a plate and a threaded spindle or ball joint. Any plate can be combined with any threaded spindle or ball joint. The anti-slip plate absorbs vibrations and prevents the swivel foot slipping. For matching threaded spindles see 27810. For matching ball joints see 27811.

Request for a quote

SIKO GMBH

Germany

Robust and economic plastic handwheel. Various sizes. Hub made of zinc-coated steel for high stability and easy shaft mounting. Various hub versions. With thread for mounting a turning handle (see accessories).

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting*nickel plated*vinyl coated handles*width of mouth 59 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting, nickel plated*vinyl coated jaws*capacity 0 – 40 mm

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

zinc diecasting, nickel plated*vinyl coated jaws*capacity 0 – 40 mm

Request for a quote

TOX-DÜBEL-TECHNIK GMBH

Germany

Features • Tension- and pressure-resistant fastening • No backing or wedging of the frame necessary • Corrosion protection due to aluminium-zinc coating • Fire resistant to DIN 4102 (class A1) Description & Area of Application • Galvanized metal frame wall plug, pre-assembled with metric countersunk screw M6 (driver PZ3) • Fire resistant to DIN 4102 (class A1) • Tension- and pressure-resistant fastening • Tightening the screw pulls the cone into the sleeve and spreads it open

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER synchronizing pulleys can be made of such different materials as aluminum, steel, stainless steel, gray cast iron or plastics. The fact that they can be produced with all pitches and designed according to your specifications and drawings ensures an optimal solution for any application. Our synchronizing pulleys work together optimally with our extensive and complete range of timing belts. Together they are a perfectly matched system for your application. We have a large range of standard pulleys on stock, which can be reworked according to your specifications. Special surface coatings, such as hard coating, anodizing, zinc coating, bronzing, improve the corrosion and wear resistance.

Request for a quote

NOVELTY STEEL

Turkey

Galvanizing is the process of applying a protective zinc coating to prevent rusting. The most common method is hot-dip galvanizing, where the steel parts are submerged in a bath of molten zinc. Hot dip galvanization is a highly-specialized job therefore at Novelty Steel, unlike painting works, galvanization works are subcontracted to the specialized subcontractors. Although it is a more expensive type of coating compared to 2 layer organic paint coating, hot dip galvanization offers the below great advantages; Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

Turned parts, CNC turned parts, long turned parts Part diameter: 0.3 to 200 mm Parts Length: 1000 mm Materials: steel, stainless steel, brass, aluminum and plastic In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

Turned parts, CNC turned parts, long turned parts Part diameter: 0.3 to 200 mm Parts Length: 1000 mm Materials: steel, stainless steel, brass, aluminum and plastic In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc.

Request for a quote

VOSSLOH-VERBINDUNGSELEMENTE, INH. MICHAEL VOSSLOH E.K.

Germany

Thickness and strength: 0.3 to 100 mm Parts length: to 500 mm Materials: steel, stainless steel, aluminum and plastic In association with our high qualified partners the supply of hardened and coated standard parts is self-evident. Our products are galvanized on request, painted, anodised, phosphated, zinc flake coated (e.g. GEOMET) etc

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER synchronizing toothed shafts can be made of such diff erent materials as aluminum, steel or stainless steel. The fact that they can be produced with all pitches and designed according to your specifications and drawing ensures optimal solutions for all applications and any loads. Our synchronizing toothed shafts work together optimally with our extensive and complete range of timing belts. Together they are a perfectly matched system for your application. We have a large range of standard pulleys on stock, which can be reworked according to your specifi cations within a short time (e.g. bores and machining based on your drawings). Special surface coatings, e.g. such as hard coating, anodizing, zinc coating or bronzing, improve corrosion and wear resistance.

Request for a quoteResults for

Zinc coating - Import exportNumber of results

138 ProductsCountries

Company type

Category

- Industrial piping (6)

- Electric cables (5)

- Galvanization - steels and metals (5)

- Locks, bolts and keys (4)

- Stamping - steels and metals (4)

- Turning - steels and metals (4)

- Conveyor belts (3)

- Garden fittings (3)

- Milling - steels and metals (3)

- Screw cutting - steels and metals (3)

- Voltage stabilisers (3)

- Automation - systems and equipment (2)

- Clamp collars, plastic (2)

- Cutting - steels and metals (2)

- Fasteners, metal (2)

- Folding - steels and metals (2)

- Heating, domestic - installations and equipment (2)

- Magnets (2)

- Sheet metal and strips, tinplate (2)

- Shelving for shops (2)