- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- semiconductor

Results for

Semiconductor - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

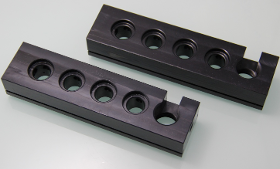

These are the small and exquisite products,which made by aluminum,after 3-axis machining,then natural anodize.

Request for a quote

IGUS® GMBH

Germany

The T3 system combines smooth operation, low noise, simple assembly, and economy. The side bands, which snap together, replace a conventional pin and bore connection and prevent relative movements between the joints giving extremely low wear. This means virtually no wear or abrasion (cleanroom). The t-band's geometry means that hardly any polygon effect is generated when the energy chain is placed. The t-band therefore rolls in a very smooth arc, giving extremely low vibration and noise. In order to reduce the manufacturing and installation costs, the t-band is not mounted individually, but – much like the E3 system – in an eight-link length. Due to its low mass, the t-band is suitable for applications with low fill weights and short strokes combined with high speeds and accelerations.

Request for a quote

IGUS® GMBH

Germany

Aside from the tried-and-tested uses of the E6, the new generation offers additional advantages which significantly simplify operation. In addition, design changes have improved accessibility to the interior, reduced weight and made assembly easier. - Option without camber (NC) simply by turning the inner link - Extremely quiet due to the small pitch and "brake" in the stop-dog system - (E61.29.070.055.0 at 1m/s = 32dB(A) according to igus internal test 4479) - Extremly low vibration - Low-abrasion connector system (no bolts and holes necessary) - Virtually no polygon effect, thereby "smooth rolling" operation - Smooth interior design for a long lifetime for cables and hoses - E61.29 series: cross bars on both sides can be snapped open and removed along the inner and outer radii - Weight savings approx. 30% compared to the E6 system - Cost-effective

Request for a quote

NIPPON KORNMEYER CARBON GROUP GMBH

Germany

With its complete array of material and process competencies, NKCG serves all types of semiconductor applications. NKCG has been a reliable partner for semiconductor material producers and device makers for decades, bringing its vast experience to improve processes.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Aluminium CNC milling part in black anodize finish Tolerance:+/-0.05mm, Critical holes and threads Surface rougness:Ra1.6 CNC Machining parts, Machining in Aluminium stainless steel,brass,copper, titanium,POM and so on. Aluminium housing, Blocks, flanges, valve seat, supporter CNC Turning parts ,Machining in Aluminium stainless steel,brass,copper, titanium,POM and so on.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Excellent performance with porous vacuum componets Manufacturers around the world trust our porous materials to deliver excellent performance when used as vacuum components. Anti-static additives can also be introduced for applications that require conductivity. Ensure purity–Material is backed by the Certified Pure POREX™ program of independent laboratory testing of leachables, extractables and interfering substances. Deliver precise flow rates and tolerances–Engineered for tight pore size and volume control. Improve device effectiveness–Design is customizable per application and can incorporate anti-static properties. request sample ask an engineer

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Enhance semiconductor processing with pure materials Our high-purity diffusion tubes allow semiconductor processing facilities a precise way to diffuse, filter and distribute process gases. Specifically designed to precise flow and dimensional tolerances, POREX® diffusion tubes: Ensure purity –Material is backed by the Certified Pure POREX™ program of independent laboratory testing of leachables, extractables and interfering substances. Deliver precise flow rates and tolerances–Engineered for tight pore size and volume control. Improve process effectiveness–Design is customizable per application requirements. request sample ask an engineer

Request for a quote

MICRO-EPSILON

Germany

For the steel and aluminum industry, Micro-Epsilon offers innovative measuring and inspection systems for thickness, profile and surface measurements. Performance and quality, as well as reliability of products and services have made Micro-Epsilon one of the leading suppliers of inspection systems for optical thickness measurement used in the metals industry. Our non-contact thickness measuring systems are used wherever high-precision thickness monitoring is required for control and quality assurance. Both in hot rolling mills, in continuous casting plants and in cold rolling mills and service centers, the Micro-Epsilon measuring systems operate reliably and with maximum precision. Numerous, successful installations in 13 countries around the world in milling lines and processing lines speak for themselves.

Request for a quote

MICRO-EPSILON

Germany

surfaceCONTROL sensors are used for 3D measurements and surface inspections. The sensors use the fringe projection principle to detect diffuse reflecting surface and to generate a 3D point cloud. This point cloud is subsequently evaluated in order to recognize geometry, extremely small defects and discontinuities on the surface. Sensors with different measurement areas are available. This enables the inspection of the finest of structures on components as well as form deviations on large-area attachments. Powerful software packages are available for evaluation and parameter setting.

Request for a quote

MICRO-EPSILON

Germany

The CLS1000 controller is available in five different versions: CLS1000-QN with antivalence function (normally open/normally closed), CLS1000-2Q with two switching outputs, CLS1000-OC with optocoupler, CLS1000-AU with voltage output and CLS1000-AI with current output. Each model is available in NPN, PNP or push-pull versions. All controllers are available with or without triggers.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

The Hiresta – UX measuring device is used to measure semiconductors or non – conductors (insulators). Measuring range of 10^3 – 10^14 Ω . The Hiresta UX is specialised in measuring the resistance, the surface and volume resistivity of various substances and materials of all shapes and sizes in the high-resistance measuring range. For measurements related to the ASTM D257 / ISO 2951 / JIS K 6911 standard of: antistatic materials flooring materials paper, packaging materials paints, pastes, paints fibers, clothes, fabrics adhesives, greases glass, concrete, ceramics plastics, film materials, foils etc. Up to 2000 measurement results can be exported to USB memory stick The conductivity meter impresses with its compact design, a color 7.5 “TFT touch display and user-friendly menu navigation.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

The Loresta GX is used to measure conductors and semiconductors in the lower resistance range. Measuring range: 10^-4 – 10^7 Ω. It is used to measure the surface resistivity (Ω / □), the volume resistivity (Ω · cm), electrical conductivity (S / cm) in the low-resistance range. The Loresta-GX works according to the 4-pin measuring method. The method is based on the four-wire method and was developed to eliminate the influence of contact resistance. The measuring heads consist of four needle-like electrodes. To simplify the measurement method and calculate the correction factors, all four electrodes are at an equidistant distance from each other. Conductive Materials: Paints, pastes, paints, printing ink, Smart Textiles, Plastics, rubber Film materials, metallic thin films, metallised films, resistor pastes amorphous silicon / silicon wafer, antistatic materials, EMC shielding materials ...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

In the manufacture of semiconductors, agitators are mainly used in conditioning of polishing and cutting suspensions, etchants and other auxiliary chemicals, cleaning solutions, or in chemicals recycling. Requirements placed on stirring systems are extremely demanding. Almost always, clean room conditions prevail, meaning that drives and seals must be designed with no abrasion or leakage. Parts that come into contact with the medium, such as the shaft and stirring element, often have to be produced with metalfree surfaces due to the aggressiveness of the media and the purity requirements. Also in this area, Geppert Ruhrtechnik can look back on a very successful history. All well-known chip manufacturers belong to our client base, as well as the manufacturers of the specialty chemicals used in this field. In addition, our agitators are used in broad solar cell production areas.

Request for a quote

LEICA MICROSYSTEMS

Germany

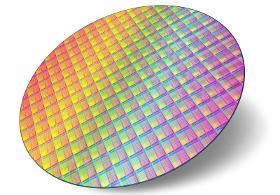

Speed matters in inspection, process control, or defect and failure analysis for the microelectronics and semiconductor industry. The faster you detect a defect, the faster you can react. With a large field of view, the DM3 XL inspection system allows your team to identify defects faster and increase your yield rate. Make use of the 30% increased field of view of the unique macro objective. Additionally, the DM3 XL uses LED illumination for all contrast methods. LED illumination provides a constant color temperature and offers real color imaging at all intensity levels. - Increase your yield - Reliably detect insufficient development at the edge or within the center of a wafer - Detect uneven radial film thickness - True-to-life color imaging at all intensity levels - Reproducible results

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Compact design for space saving. Just push plug into socket for connection. Simply push the button on the socket for disconnection. Suitable for a wide range of applications from medical/scientific equipment to beverage machines or semiconductor manufacturing devices. When valveless type socket or plug is used, fluid will flow out of it when disconnected.

Request for a quote

3D-MICROMAC AG

Germany

The microDICE™ laser micromachining system leverages TLSDicing™ (thermal laser separation) – a unique technology that uses thermally induced mechanical forces to separate brittle semiconductor materials, such as silicon (Si), silicon carbide (SiC), germanium (Ge) and gallium arsenide (GaAs), into dies with outstanding edge quality while increasing manufacturing yield and throughput. Compared to traditional separation technologies, such as saw dicing and laser ablation, TLS Dicing™ enables a clean process, microcrack free edges, and higher resulting bending strength. Capable of dicing speeds up to 300mm per second, the microDICE™ system provides up to a 10X increase in process throughput compared to traditional dicing systems. Its high throughput, outstanding edge quality and 300mm wafer capable platform enables a true high volume production process, especially for SiC based devices.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Semiconductor - Import exportNumber of results

18 ProductsCountries

Category

- Semiconductors (4)

- Sensors (3)

- Measurement - Equipment & Instruments (2)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Coupling, pneumatic (1)

- Engine testing and regulating equipment - electronic (1)

- Laser - cutting and welding machines (1)

- Milling - machine tools (1)

- Polishing - machine tools (1)

- Steels and metals - machining (1)

- Vacuum cleaners - industrial (1)