- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing line

Results for

Processing line - Import export

MESUTRONIC GMBH

Germany

FOR INSTALLATION IN PNEUMATIC FIBRE PROCESSING LINES Reliable metal and spark removal. Minimal ejection loss through ultra-fast switching time. Extremely robust – 300,000 switches without visible wear. Suitable for pressure and suction transport.

Request for a quote

MICRO-EPSILON

Germany

For the steel and aluminum industry, Micro-Epsilon offers innovative measuring and inspection systems for thickness, profile and surface measurements. Performance and quality, as well as reliability of products and services have made Micro-Epsilon one of the leading suppliers of inspection systems for optical thickness measurement used in the metals industry. Our non-contact thickness measuring systems are used wherever high-precision thickness monitoring is required for control and quality assurance. Both in hot rolling mills, in continuous casting plants and in cold rolling mills and service centers, the Micro-Epsilon measuring systems operate reliably and with maximum precision. Numerous, successful installations in 13 countries around the world in milling lines and processing lines speak for themselves.

Request for a quote

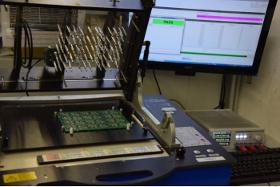

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Test contacts on the circuit board, produced for just this purpose, are contacted by fine, spring-loaded test pins. Depending on the series size, the in-circuit test can take place manually or in an automated fashion. In combination with other test processes, including tests without test contacts, over 90 percent of all errors can be detected.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METZNER MASCHINENBAU GMBH

Germany

This special Metzner development is able to process cable wires with a diameter of up to 28 mm. The cycle time for this is 2000 mm / 35 seconds. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings. As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The specially developed production line can unwind, label, roughen, cut to length, strip, wind, bind and automatically deposit the cable wires. The material to be processed is unwound by a motorised unwinder and fed to a thermal transfer printer via a straightener. The latter prints the cable with two QR codes and a serial number. This ensures that each cable can be identified throughout the entire processing and manufacturing process and assigned to the stations which have already passed through. This traceability offers great advantages – for example in the diagnosis of faults. The cable then passes through a roughening station, which lightly roughens the material surface so that the connector overmoulding adheres better later on. An AM 3550 from Metzner Maschinenbau cuts to length and strips the cable, which is then transported to the winding station and onwards by a gripper to the binding machine. The latter winds the cable to form a cable ring.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

An internationally active medical technology company that produces and sells catheter tubes, among other things, has optimized its manufacturing process with the help of a production line from Metzner Maschinenbau. With Metzner's know-how, it was possible to replace a costly manual process with an automatic machine, saving costs. At the same time, the length accuracy and the cutting quality were significantly improved. The company supplied a fully automatic system that precisely cuts the catheter tubing to length, removes the mandrel present from the extrusion without leaving any residue and without longitudinal expansion, and then deposits the tubing in a collecting container at the end. Processing with exact length accuracy and mandrel removal The Metzner special development cuts catheter tubes to an exact length and removes the mandrel inside safely and precisely. The finished material is deposited in a collection container.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has a clear understanding of the future and transforms existing processes into fully automated system solutions. Workstations that were previously operated separately are now combined into fully automatic production lines. The starting point of an automatic processing line is the cable that is wound on a reel. The end result is a finished cable with a completely assembled plug system

Request for a quote

WECKERLE MACHINES

Germany

The UF is Weckerle’s ultimate high speed filling machine with large output production. This machine is able to run a wide range of products with different volumes and diameters, such as chap sticks, make-up sticks, deodorant sticks/ tubes and various other products. The straightforward machine handling provides a highly efficient operation.

Request for a quote

WECKERLE MACHINES

Germany

The MultiStick is able to tailor up to 6 different forms and capable of filling up to 6000 lipsticks per hour in 24/7 operation. Thanks to the new Plug & Play Technology with the rail mounting system for process stations, the machine can be easily upgraded without major frame rework. It also offers an optimized footprint with integrated compounding. The MultiStick assures the ultimate process flexibility in the whole filling technology.

Request for a quote

WECKERLE MACHINES

Germany

Weckerle’s MM machine series, enables you to fill lipsticks and/or lip balms with different moulds in various shapes, diameters, and output. With these machines, Weckerle assures the ultimate perfection in the lipstick filling process. MultiMould Lipstick Filling and Processing Line MM 60: The fully servo-driven machine features 60 interchangeable moulds to customer’s specification for filling various hot poured cosmetic sticks such as lipstick, slim stick, lip balms, and make-up sticks. MM 180: The fully servo-driven MM 180 features 180 interchangeable moulds to customer´s specification for filling various hot poured cosmetic sticks such as lipstick, slim stick, lip balms, and make-up sticks. MM 360: The fully servo-driven MM 360 features 360 interchangeable moulds to customer´s specification for filling various hot poured cosmetic sticks such as lipstick, slim stick, lip balms, and make

Request for a quote

WECKERLE MACHINES

Germany

Lipstick Filling and Processing Line The L 1800 is a sustainable and economical solution to serve all types of manufacturers of cosmetic products. The very compact L 1800 is able to produce up to 1.800 lipsticks per hour in 24/7 operation. Furthermore, the machine can be upgraded very cost-efficient for producing top filled products such as lipgloss, making it our most compact multi-functional machine available. Features: Weckerle Soft Mold Lipstick Molding Technology, Ergonomically comfortable machine with simple and intuitive handling, Small footprint enables highly efficient use of workspace, Innovative quality inspection camera

Request for a quote

HEXPOL TPE GMBH

Germany

TPE compounds for plastic closures using the in shell liner moulding process The EPSeal 800 series was developed for PE and PP closures specially designed for the in shell moulding liner technology. The series includes versions for cold fill, pasteurisation and hot fill beverage treatment systems. This series also includes versions with different rheological values to address the special processing requirements of different lining machine types. An assortment of lubricant packages addresses the spectrum of closure and liner profile designs but all lead to a neutral taste and odour sealant whilst remaining consumer friendly and reliable. Download EPSeal Product Guide

Request for a quoteResults for

Processing line - Import exportNumber of results

15 ProductsCompany type