- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dry system

Results for

Dry system - Import export

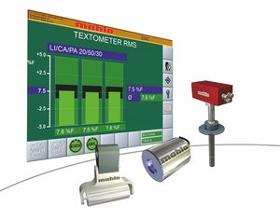

MAHLO GMBH & CO. KG

Germany

Optimizes drying The Ecopac EMC uses the state of the art microprocessor technology to ensure product quality and optimise the energy balance for drying processes. The modular system for monitoring and controlling residual moisture, product temperature, dwell time and exhaust air humidity can be flexibly adapted to current production. Up to three of the same or different modules may be used as needed. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, joints and slideways at high temperatures Conveying systems in painting, stoving and drying systems Food-processing machines Advantages and benefits Can be used up to 250°C NSF H1 registered, conforms to the requirements of the Hazard Analysis Critical Control Points (HACCP) method in the food processing industry Good adhesion on metal surfaces Excellent water resistance Excellent oxidation properties Excellent wear protection MOSH/MOAH-free

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, joints and slideways at high temperatures Conveying systems in painting, stoving and drying systems Food-processing machines Advantages and benefits Can be used up to 250°C NSF H1 registered, conforms to the requirements of the Hazard Analysis Critical Control Points (HACCP) method in the food processing industry Good adhesion on metal surfaces Excellent water resistance Excellent oxidation properties Excellent wear protection Also available as spray version OKS 3571 MOSH/MOAH-free

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Gearbox lubrication of heavily loaded, relatively slow-running toothed gearing when grease is used instead of oil due to leaks For heavily loaded and impact-loaded drives Chain lubrication, e.g. of hollow-pin chains in the conveyance and transport sector, for exposure to water and steam and at higher operating temperatures Bearing lubrication of friction and rolling bearings in annealing yards and drying systems, manipulators and robots, cooling-bed and conveyor systems, machines in food packing industry, steam sterilisers etc. Advantages and benefits Excellently suited for corrosive operating conditions with high operating temperatures and high pressure and impact loads Economical due to optimised formula Enables wear reduction, decreasing failure times and enabling long-term lubrication Long-acting, highly adhesive, temperature-stable and waterproof, noise-damping, impact and pressure resistant

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, fringe bearings, hinges, joints, clamping and drying frames or slideways at higher temperatures and loads For conveying systems under radiation heat in painting, stoving and drying systems Advantages and benefits Highly effective due to finest, homogeneous MoS₂ distribution in the oil Emergency running properties through MoS₂ at dry running Outstanding adhesion and lubrication effect with no tendency to drip or dry out Silicone-free For best adhesion, clean the surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. With a brush, drip oiler or by immersion or using a suitable automatic lubrication system, apply a sufficient quantity to the locations to be lubricated. Allow excess to drip off. Allow OKS 350 to soak in before operating. Observe the machine manufacturer's instructions. Assess the lubrication frequency and quantity on basis of service conditions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of plain and rolling bearings in high-temperature range, where a mineral oil based grease cannot be used, e.g. on hot-air blowers and fans, autoclaves, drying ovens or systems in steelworks and foundries Advantages and benefits Drip-free hot bearing grease for a broad temperature range with high oxidations stability and moisture resistance Excellently suited for long-term lubrication of grease lubricating points subject to high-temperature loading Highly effective due to optimum high-performance formula Broad range of uses outside normal grease performance areas

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Viscotemp 2. Fully synthetic high-temperature lubricating grease Description Castrol Molub-Alloy 100-2 HT (previous product name Castrol Viscotemp 2) is a fully synthetic high-temperature lubricating grease for use at high continuous temperatures. It enables long-term lubrication of plain and rolling bearings and other grease lubrication points at high operating temperatures, high bearing pressures and aggressive environmental conditions. Application Castrol Molub-Alloy 100-2 HT is a high-temperature grease for the lubrication of rolling and plain bearings and is used in fan bearings in hot air flow, calender bearings, baking systems and continuous drying chambers as well as for overhead conveyors of painting lines that are exposed to chemical influences, as well as in cold or influence of hot water and steam. Instructions for use Temperature range: -20 °C to +220 °C

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Viscotemp 2. Fully synthetic high-temperature lubricating grease Description Castrol Molub-Alloy 100-2 HT (previous product name Castrol Viscotemp 2) is a fully synthetic high-temperature lubricating grease for use at high continuous temperatures. It enables long-term lubrication of plain and rolling bearings and other grease lubrication points at high operating temperatures, high bearing pressures and aggressive environmental conditions. Application Castrol Molub-Alloy 100-2 HT is a high-temperature grease for the lubrication of rolling and plain bearings and is used in fan bearings in hot air flow, calender bearings, baking systems and continuous drying chambers as well as for overhead conveyors of painting lines that are exposed to chemical influences, as well as in cold or influence of hot water and steam. Instructions for use Temperature range: -20 °C to +220 °C

Request for a quoteResults for

Dry system - Import exportNumber of results

9 ProductsCountries

Company type