- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dry system

Results for

Dry system - Import export

KLN ULTRASCHALL AG

Germany

After cleaning we use drying systems in order to achieve spotless drying, to protect corrosion-sensitive parts or to avoid water intake into production. The drying systems can be integrated in manual or fully-automatic cleaning processes. KLN manufactures various drying systems in several versions.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

The new LUXOR swift 250 dry air generator offers the ideal price-performance ratio for standard applications in the drying of granulate. The LUXOR swift 250 has a dry air capacity of 250 m³/h. The dry air generator can either be operated with a single drying bin or combined with multiple preconfigured drying bins in your plant. The drying bins are available from 100l to 900l sizes. This gives you the maximum possible flexibility and an uninterrupted production flow. For more energy efficient drying, additional functions such as dew point control or return air cooling can be added. Versatile use Different drying bin sizes for different applications Thanks to motan’s automatic air regulation the drying process can be optimized. Different sizes of drying bins with integrated heating allow a wide range of applications with proven motan drying technology.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

The COMPACT swift dryers are designed with flexibility in mind. They offer an integrated solution, combining the drying and conveying of the raw material in one unit. The dryers are available in two versions and are each equipped with one drying bin of the size 80 or 150 litres and up to 2 hopper loaders with a capacity of 4 litres each. The COMPACT swift A dryer is provided with advanced functions such as dew point control and dry air conveying function with line purging. Thanks to a modern 7-inch colour display with touch screen, all conveying and drying functions can be shown and monitored in a user-friendly way. 16 user languages can easily be selected.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

LUXOR A series dryers with ETA-process® and ETA plus® energy saving technology are specifically designed for supplying dried plastic granulate for many different plastics processing applications. They have either two or three fully insulated stationary desiccant beds with separate process and regeneration blowers which provide consistently low dew-point air to the process, while reducing energy consumption. The advanced LUXOR A series consists of ten models with drying capacities from 80 to 2400 m3/h. Each advanced system dryer can be flexibly combined with all LUXORBIN A drying bins from 15 to 2400 litres. In addition, motan offers a range of extra-large drying bins with volumes from 3,000 to 13,000 litres. These are also available with gas heating. All motan system drying bins are made of stainless steel, are completely insulated, and have individual heating as well as temperature control.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

LUXOR S dryers operate at maximum efficiency and with minimum operating maintenance. The opportunity to have multiple material bins connected to one dry air generator provides our customers with maximum flexibility and no interruption to production. Drying can continue while material is changed in any one bin, minimising loss of valuable production time during material changes. The compact LUXOR S series consists of five models with drying capacities from 40 to 160 m3/h. Each dry air generator can be flexibly combined with a combination of drying bins ranging in size from 15 to 600 litres.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

LUXOR HD hot air dryers offer the most effective way of conditioning moderately hygroscopic plastic granules for processing and removal of surface moisture. Pre-heating of raw materials stabilises the production parameters and reduces processing energy costs. motan‘s fully insulated LUXOR HD hot air dryers cover a performance range from 7 to 1100 kg per hour. The dryers can either be mounted directly on the throat of the processing machine (up to 150l) or on a support frame beside the machine.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Both the LUXOR E A and LUXOR EM A dryers with optional ETA plus® energy saving technology are specifically designed to supply consistently low dew-point air to one drying bin, while reducing energy consumption. The LUXOR E A dryer is designed for use with existing conveying systems or hopper loaders. Whereas the LUXOR EM A offers a machine dedicated solution with integrated dry air conveying for up to two processing machines and the drying bin. There are three sizes with drying bin capacities of 60, 100 and 150 litres. The LUXORnet controls utilise modern, flexible BUS-technology. As standard, the colour touch control manages the dry air generator, one drying bin and with the EM version, material conveying to one drying bin and two processing machines. The integration of dry-air conveying and material proportioning provides maximum flexibility and productivity.

Request for a quote

ROBINSON CO.

Turkey

It is used to separate heavy foreign materials such as stones, glass and metal pieces or soil pieces in the grain with the help of screening method and air. The machine consists of a fixed chassis and vibrating body. The stone separator, designed considering the difference in density of stone and grain, separates the stone by directing the grain in the direction of gravity, in the opposite direction of gravity, with the help of vibration. Wheat is separated from the stones with the help of a vibrating sieve. In addition, dust is absorbed by the air aspiration provided from the ventilation line. Apart from flour and semolina factories, it is also used in all grain factories, vegetable oil factories, cocoa and coffee processing plants. Application Fields ◾ At food industry ◾ Flour and semolina mills ◾ Cereal cleaning plants ◾ Corn factories ◾ Oil factories ◾ Malt factories ◾ Cacao and coffee plants

Request for a quote

PARSMEGA MAKINA

Turkey

Stone separation machines are used in flour factories to separate materials such as stone, metal, glass and soil in wheat that have a specific gravity different from wheat. It is an indispensable machine especially for dry system cleaning units. Stones and similar substances can easily enter the wheat from nature. If these substances are not separated from the wheat, the flour or ash content will be high as a result of grinding. This is also an undesirable feature.

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

Mechanically robust and with a chemical and condensed waterproof sensing area, the digital IST AG HYT humidity modules offer a wide application window and an optimal price-performance ratio. Precisely calibrated, the HYT modules deliver an outstanding accuracy and excellent long-term stability even at high humidity - ideal for sophisticated mass applications, industrial handheld devices and precise humidity transmitters. Advantages of the HYT 221 digital humidity module include: — Calibrated and temperature compensated — Excellent humidity/temperature accuracy and stability — High chemical resistance — I2C protocol (address 0x28 or alternative address) — Wide humidity and temperature range (0 % RH to 100 % RH and -40 °C to +125 °C) — Very low drift — Very stable at high humidity — Interchangeable without adjustments

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

Mechanically robust and with a chemical and condensed waterproof sensing area, the digital IST AG HYT humidity modules offer a wide application window and an optimal price-performance ratio. Precisely calibrated, the HYT modules deliver an outstanding accuracy and excellent long-term stability even at high humidity - ideal for sophisticated mass applications, industrial handheld devices and precise humidity transmitters. Further advantages of the HYT 939 digital humidity module include: — Calibrated and temperature compensated — Excellent humidity/temperature accuracy and stability — High chemical resistance — I2C protocol (address 0x28 or alternative address) — Wide humidity and temperature range (0 % RH to 100 % RH and -40 °C to +125 °C) — Very low drift — Very stable at high humidity — Interchangeable without adjustments — Pressure-resistant version (up to 16 bar) upon request

Request for a quote

SEMIN

France

TECHNICAL DEFINITION • White fine grain repair filler for interior and exterior use • Does not shrink • High resin content • FINEX SYSTEM is a multi-purpose filler, which allows to fill holes and cracks, and to repair windowsills and damaged angles ACCEPTED SUBSTRATES Cement, concrete, bricks, concrete blocks, stone, aerated concrete, plaster, old paint, old tiling. SUITABLE SURFACES Once completely dry, FINEX SYSTEM can be covered with all types of paint, watertightness system, plaster- or cement-based fillers, and silicate, epoxy or polyurethane paint. TECHNICAL CHARACTERISTICS • Grain size : fine • Adhesion : complies with standard DTU 42.1 • pH : 9 once dry • Setting starts after 50 minutes • Setting ends in 1 hr 10 min PREPARATION OF SURFACES BEFORE APPLICATION The substrate must be clean, dry, free of dust and of any trace of stripping oil. Walls that are peeling off must be scraped beforehand. Strip any old paint in poor condition and remove any old thick plastic covering.

Request for a quote

PERGEL METAL

Turkey

The paint plant is especially preferred in the construction and furniture industry. The materials used in this sector are painted both for aesthetic purposes and for protection purposes. Paint plants is a far-reaching term. There are varieties. Its quality and form vary. In general, the age paint plant is more preferable. There is a wet paint booth, conveyor system and drying oven in the paint plant. It is produced in accordance with the most suitable conditions and made suitable for use.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dry cleaning systems The dry alternative for cleaning Easy on the material & thorough Many years of experience with the working processes and requirements of our customers led us to develop an alternative cleaning system. The term alternative is appropriate, because in contrast to using conventional washing machines we have taken a completely different path. Whereas they work with wash emulsions everything remains dry on our cleaning system equipped with a linear brush unit – but it is just as thorough! Features & benefits • Clean coils/blanks economically without “washing agents” • Best cleaning performance • Rugged steel construction suitable for press shops • Low maintenance For all sheet metals and blanks Our dry cleaning system is suitable for material widths from 500-4500 mm. It cleans individual profiled sheets of metal, galvanised blanks, tailored blanks and much more. The system not only effectively removes interfering particles, but at the same time it also homogeniz

Request for a quote

CRYOSNOW GMBH

Germany

• Small required space • Integration in injection molding machines, especially for in-mold-decoration • Easy installation on robots, linear axle and brackets • Separate 24V control of compressed air and CO2 • Liquid CO2 supply with CO2 cylinder bundles including dip tube or CO2 tanks • Short response time due to additional CO2 valve on the nozzle • Automated cleaning of injection molds, metal and plastic parts

Request for a quote

CRYOSNOW GMBH

Germany

• Heats up the compressed air up to 100 °C (212 °F) • Total avoidance of condensation • Simple and accurate temperature control • Easy to fix on control unit • Also suitable for dry ice blasting machines with CO2 pellets • For the cleaning of switch cabinets, thin metal sheets, electronic components

Request for a quote

CRYOSNOW GMBH

Germany

• For automized applications • CO2 consumption is controlled by pressure and temperature • Compact design, overall length 134 mm (5.3") • Customer-specific robot adapter • Weight without robot adapter 3.9 kg (8.7 lb) • No water condensation due to high efficient thermal insulation • Process reliable and maintenance-free in permanent operation • Cleaning width 200 mm (7.8")

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CRYOSNOW GMBH

Germany

• Especially for automized applications • Very short, compact design, overall length including short flat nozzle 330 mm (13") • Installable as extension of the last axis of the robot • Overall weight including short flat nozzle 2 kg (4.4 lb) • No water condensation due to thermal insulation • Process reliable and wearless in permanent operation • Jetting width up to 125 mm (4.9") • For the cleaning of big surfaces in pretreatment before painting • For use with different nozzles

Request for a quote

CRYOSNOW GMBH

Germany

• Extreme low consumption • For difficult to access and delicate parts • For automated blasting operations • Adaptable for use with every type of robot • No build up of ice, as thermally insulated • With CO2 quantity controller

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This automatic washing & drying system provides high efficient cleaning of elastomers in through-feed method (on option washing with de-ionized, de-mineralized or ultra-pure water possible). Starting from the loading station, the washing drums are conveyed automatically to each washing station (→ station pre-washing → station rinsing → station high pressure cleaning → station high pressure drying) and are finally conveyed to the unloading station after treatment. The dimensions of this system depend on the drum dimensions desired (perforation from 3 - 15 mm possible by choice). Set as our default, the models WD3, WD5 and WD9 are available with different sizes. For industry 4.0 demands, this system is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. Siliconisation or other coating of elastomers is possible on option.

Request for a quote

CRYOSNOW GMBH

Germany

• Control cabinet with process control, inspection and monitoring for automated applications • Integrated control and safety components • Simple, ergonomic operation • For use with stationary CO2 tank (or bundles) • Modular construction, design according to customer requirements

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO CO2 Gas Revert Recovery Systems are engineered to efficiently recover the revert CO2 gas from ASCO Dry Ice Pellet and Block Machines which normally direct the revert (flash) gas to the atmosphere. When dry ice is produced the conversion rate from liquid CO2 to dry ice is approx. 4045 %. This means 5560 % is lost to the atmosphere. This conversation rate is a physical fact and therefore, unfortunately, not to change. With a CO2 Revert Recovery System, however, most of the CO2 can be recovered which leads to a final conversion rate of approx. 9095 %. This way, the dry ice production costs are reduced up to 50 %.

Request for a quote

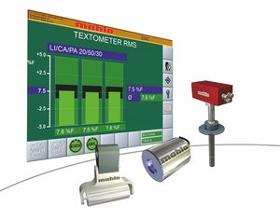

MAHLO GMBH & CO. KG

Germany

Optimizes drying The Ecopac EMC uses the state of the art microprocessor technology to ensure product quality and optimise the energy balance for drying processes. The modular system for monitoring and controlling residual moisture, product temperature, dwell time and exhaust air humidity can be flexibly adapted to current production. Up to three of the same or different modules may be used as needed. This increases quality while saving resources and energy. The modular design of the system allows its flexible adaptation to all applications. Both, standard requirements and highly customized demands are thus met.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, joints and slideways at high temperatures Conveying systems in painting, stoving and drying systems Food-processing machines Advantages and benefits Can be used up to 250°C NSF H1 registered, conforms to the requirements of the Hazard Analysis Critical Control Points (HACCP) method in the food processing industry Good adhesion on metal surfaces Excellent water resistance Excellent oxidation properties Excellent wear protection MOSH/MOAH-free

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of chains, joints and slideways at high temperatures Conveying systems in painting, stoving and drying systems Food-processing machines Advantages and benefits Can be used up to 250°C NSF H1 registered, conforms to the requirements of the Hazard Analysis Critical Control Points (HACCP) method in the food processing industry Good adhesion on metal surfaces Excellent water resistance Excellent oxidation properties Excellent wear protection Also available as spray version OKS 3571 MOSH/MOAH-free

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 6/2 is designed for up to 9,300 residents, and is able to provide drainage for small towns. The proven separator system is also used in this size, and the systems are installed dry. System operation and maintenance are very user-friendly. The pump controls are designed according to the user's needs and mounted in an external cabinet. Additional accessories are available for this system, please submit your inquiry. Draining towns with up to about 9300 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves One Y-pipe DN 200

Request for a quote

ENVEA

France

The dry extractive SEC™ system dries the gas sample at the sampling point, eliminating the necessity of an expensive heated sampling line.

Request for a quote

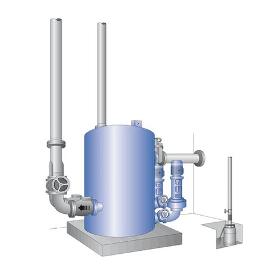

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Every year, millions of tons of household garbage and other refuse are deposited in landfills around the world. Bio-chemical decomposition processes of organic bonds in these landfills produce up to 150 - 250 m of landfill gases per tonne of household garbage. Due to a methane content of up to 60%, landfill gas ranks number six on the list of climate-disrupting methane producers worldwide, but it is also an important source of energy with enormous potential if used sensibly. Up to a content level of approximately 40% methane, landfill gas may still be recovered usefully in modern block heating plants. The important factor in this case is an effective and project-specific pre-cleaning process for the gas. We can help by providing you various gas cleaning systems, gas drying systems, and activated carbon filters, and pressure increasing stations. The components may be used as individual models or delivered as a complete system that is built into a container. Landfill gas...

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Gearbox lubrication of heavily loaded, relatively slow-running toothed gearing when grease is used instead of oil due to leaks For heavily loaded and impact-loaded drives Chain lubrication, e.g. of hollow-pin chains in the conveyance and transport sector, for exposure to water and steam and at higher operating temperatures Bearing lubrication of friction and rolling bearings in annealing yards and drying systems, manipulators and robots, cooling-bed and conveyor systems, machines in food packing industry, steam sterilisers etc. Advantages and benefits Excellently suited for corrosive operating conditions with high operating temperatures and high pressure and impact loads Economical due to optimised formula Enables wear reduction, decreasing failure times and enabling long-term lubrication Long-acting, highly adhesive, temperature-stable and waterproof, noise-damping, impact and pressure resistant

Request for a quoteResults for

Dry system - Import exportNumber of results

157 ProductsCountries

Category

- Plastics - machines and material for industry (7)

- Silicones (6)

- Blast cleaning equipment (4)

- Infrared tubes (4)

- Pumps (4)

- Granules for plastics (3)

- Sensors (3)

- Water - production and distribution (3)

- Air treatment - equipment and systems (2)

- Cleaning and maintenance - equipment and supplies (2)

- Flexography - machines (2)

- Granulation, plastics - machinery (2)

- Industrial robots (2)

- Lubricants, industrial (2)

- Mixers and grinders for the food processing industry (2)

- Moulding, rubber - machinery (2)

- Paint spray guns and accessories (2)

- Sanitation (2)

- Textile dyeing - machinery and equipment (2)

- Agricultural Production (1)