- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- valve system

Results for

Valve system - Import export

CIC - KLAUS CZERWONKA

Germany

The new generation of our VH series valve terminals. Modern pneumatics with economical energy consumption, compact dimensions and high flow rates. With multipolar electrical connection with D-SUB 25-pin or flat connector as standard. Core items: Reduced dimensions (15mm) Low power consumption (0.85W) High flow rate for size Compact and clear design Metal construction for a long service life even under harsh environmental conditions Fast cycle times thanks to the latest generation of magnetic coils Manual operation easily accessible LED display integrated in the magnetic coil Connection strips with modular system All islands are delivered assembled and tested

Request for a quote

CIC - KLAUS CZERWONKA

Germany

This battery system allows the assembly of a series of solenoid valves type VY in 1/8 with various functions. The electrical control is integrated in the housing and equipped with a 25-pin SUB-D connector. The valve terminal can be preconfigured and ordered fully assembled and tested, or, thanks to the very simple, intuitive coding, you can assemble it yourself on the basis.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Manual slide valves as real shut-off valves, which allow the system to be vented when it is switched off. Available in sizes 1/8 to 1/2″. Other colors such as black or red, as well as special versions with spring return or latching are available on request.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-D bin emptying system offers a modern way of emptying small containers and bins cleanly. The use of our dispenser series for the removal of the medium offers the following advantages: - container sizes from approx. 100 ml to 5 l - viscosities of approx. 80,000 - 1,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of filler-loaded material - no backflow within the withdrawal pump - electrical control of the pump with pressure control - direct dosing from the container possible - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: Removal of materials directly from the delivery container, e.g. silicones, adhesives, resins, fats, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes)

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XS hobbock emptying system offers a modern way of emptying containers.The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from approx. 5 l to 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers - direct dosing as pulsation-free flow rate

Request for a quote

ELKON GMBH

Germany

These pumps have been designed according to the most difficult conditions and heavy work.They are high performance pumps with diesel engine and S Valve System. Both models can deliver concrete up to 100 meters vertically or 300 meters horizontally. Both ELKOPOMP S45 & ELKOPOMP S60 are equipped with axle and tires. Thus, it can be easily towed and transported to required points. Moreover, the concrete delivery pipes can be easily assembled and become ready to deliver concrete. The brand of the hydraulic control unit used in ELKON Trailer Type Concrete Pumps is BOSCH-REXROTH (Germany) and the system is an open-circuit hydraulic system. ELKON Trailer Type Concrete Pumps are equipped with high quality and chrome coated concrete delivery cylinders. The system can easily regulate itself with power regulation when it delivers the concrete to higher distance by means of hydraulic pump which has variable flow, power regulation and axial piston.

Request for a quote

ELKON GMBH

Germany

These pumps have been designed according to the most difficult conditions and heavy work.They are high performance pumps with diesel engine and S Valve System. Both models can deliver concrete up to 100 meters vertically or 300 meters horizontally. Both ELKOPOMP S45 & ELKOPOMP S60 are equipped with axle and tires. Thus, it can be easily towed and transported to required points. Moreover, the concrete delivery pipes can be easily assembled and become ready to deliver concrete. The brand of the hydraulic control unit used in ELKON Trailer Type Concrete Pumps is BOSCH-REXROTH (Germany) and the system is an open-circuit hydraulic system. ELKON Trailer Type Concrete Pumps are equipped with high quality and chrome coated concrete delivery cylinders. The system can easily regulate itself with power regulation when it delivers the concrete to higher distance by means of hydraulic pump which has variable flow, power regulation and axial piston.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XL drum emptying system offers a modern way of emptying containers. The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - Bridge frame can be driven underneath with drums on pallets - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTreat-R preparation and feeding system ensures an even and reliable product supply. At the same time, the medium is optimally prepared for the production process by stirring and circulating. The use of the VRP dispenser series for the further transport of the medium offers the following advantages: optimal processing of viscosities up to 50,000 mPas very low shear stress of the medium very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - no air supply necessary - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - Stator material is adapted to the medium to be pumped Application: - Feeding and processing of medium to highly sensitive media, e.g.: Silicones, adhesives, resins, greases, colour pastes, metal-filled pastes

Request for a quote

FRIEDR. FREEK GMBH

Germany

Preformed silicone heaters are useful for diamters as small as 12 mm and up to 100 mm. Rounded silicone heaters are not possible with self-adhesive foil. Spiral Wrap Pre-Formed Silicone Rubber Heaters are suitable for tubes and flexible pipes and hoses with Ø 6,35 mm (1/4"). Spiral formed flex heaters can be used up to Ø 12 mm (the length of the stretchable silicone spiral wrap heater is reduced accordingly). The thickness of our spiral-wrapped silicone strip heaters is 2,2 mm. Also our gas and pump line heaters, most frequently used in the semi-conductor process, are shaped and pre-formed according to the object geometry to be heated. They are designed to regulate temperatures in order to prevent condensation in the line. Current applications here are Semi Conductors, Vacuum Chambers, Wafer Chucks, Valves, Exhaust & Pump Systems.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-L 3 / 18 barrel emptying system offers a modern way of emptying containers.The connection with the ViscoTec VMP dispenser series for the removal of the medium offers the following advantages: - container sizes from approx. 50 l to 300 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - removal of materials loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: Removal of materials directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

STRATE valve shafts are used in industrial and municipal areas. The different design sizes of the STRATE AWALIFT valve shafts allow the optimum size to be assigned to every individual purpose. Pipe and cable ducts, which are located exactly according to customer specifications in the manufacturing plant, meet all requirements for an exact fit, safety and ease of maintenance. Optimum, safe installation locations for valves and system components whose size allows them to be housed in a shaft Are excellently suitable as inspection shafts with flushing connection, as feeding points for AWAaerob ventilation systems, for ventilation and bleeding valves, for pig traps etc. Are made of high-quality, durable and waterproof materials with a high material strength and low material weight, with the design permitting short installation times and excluding complex

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Sealant and lubricant for cold and hot-water valves in vehicle heating systems or cooling circuits and for ground seals on glass taps and desiccators Lubrication of O-rings and rubber seals for assembly and during operation Lubrication of plastic parts Advantages and benefits NSF H1 registered Tasteless and odourless Highly effective due to excellent adhesion on all materials Neutral behaviour with regard to plastics and elastomers Completely EPDM-compatible High long-term stability without drying out, hardening or bleeding Resistant to cold and hot water, as well as acetone, ethanol, ethylene glycol, glycerine and methanol MOSH/MOAH-free

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

TOPAZ differential valves are the ideal valve for water tanks in pressurised systems. The float valve with diaphragm offers a high flow rate of up to 200 l/min. Furthermore, an adjustable level control from 50 mm up to 2500 mm is possible. This minimises the number of start-stop operations of the pump system and ensures minimal pump operation.

Request for a quote

LUTZ PUMPEN GMBH

Germany

For liquids that have to be mixed before processing and then pumped or contain small solids, the new Diaphragm pumps with an integrated air-operated Double diaphragm pump is the perfect solution. The mixing and pumping process takes place via a suction and mixing tube and a 3-way valve. The pre-assembled system is immediately ready for operation with a few simple steps and is also suitable for explosive liquids. * Mixing and pumping integrated in one system * stufenlose Regelung der Folgeplatte über Steuerventil * Media examples: Paints and varnishes, emulsions, dispersions, suspensions, water/oil mixtures, liquids with increased viscosity and solids content Features & Advantages * Quick installation and time saving through easy handling * Compact design * Base plate offers good stability on the container lid * Easy to insert into the 2" bunghole of the container by balancer or overhead crane * No further mixer necessary

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Forged components for nuclear reactors, boiler systems, piping Valves are pivotal in various industrial contexts. Forged parts designed for nuclear reactors, boiler assemblies, pipeline construction, and safety valves are crucial elements in various industrial applications. Safety valves, typically pressure relief valves, stand out as paramount safety features within most systems. Their primary function is to safeguard pressurized vessels like steam boilers, reactor vessels, and pipelines from potentially hazardous pressure surges. In the event, that pressure exceeds safe limits, these valves release trapped gases, vapors, or liquids either into the atmosphere or into designated manifold systems. The West German drop forge KB Schmiedetechnik GmbH in Hagen (NRW) boasts decades of proficiency in crafting drop-forged components tailored for pressure applications compliant with the Pressure Equipment Directive (PED) and for nuclear facilities adhering to KTA, AVSD, and RCCM standards.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

pressure equipment: valves, boiler systems, piping PED 2014/68/EU, AD 2000-W0, ASME/ASTM, CNIM, Alstom, MHPS nuclear power/ atomic energy and plant construction KTA3201.1, KTA1401, AVS D 100/50, Siemens, EDF/Areva/RCC-M naval architecture/ shipbuilding and offshore/ ocean engineering American Bureau of Shipping (ABS) Bureau Veritas (BV) Det Norske Veritas (DNV) Lloyds Register (LR) Nippon Kaiji Kyokai (ClassNK)

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

KB Schmiedetechnik GmbH is a drop forge in West Germany, located between the historic “blade & metal region” Solingen and the “soccer city” Dortmund, specializing in small series production of safety-relevant closed die forgings from 200g to 130Kg unit weight of all steel grades and alloys according to following certifications and standards: pressure equipment: valves, boiler systems, piping PED 2014/68/EU, AD 2000-W0, ASME/ASTM, CNIM, Alstom, MHPS nuclear power/ atomic energy and plant construction KTA3201.1, KTA1401, AVS D 100/50, Siemens, EDF/Areva/RCC-M naval architecture/ shipbuilding and offshore/ ocean engineering, certified by • American Bureau of Shipping (ABS) • Bureau Veritas Marine & Offshore(BV) • Det Norske Veritas (DNV) • Lloyd´s Register (LR) • Nippon Kaiji Kyōkai (ClassNK) Examples: components and equipment like brackets, holders, chain links, hoists, lifting hooks, fasteners, pressure-bearing parts like valve bodies, pipe connections, gearwheels, ...

Request for a quote

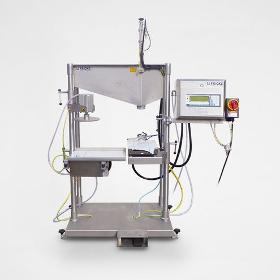

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or inks. For filling open containers, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. The System offers you: ■ calibratable above level filling ■ Thread-cutting, non-dripping filling valve ■ fast cleaning of the container (container and valve are cleaned in approx. 5 min using 1 l of solvent) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 10 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quoteResults for

Valve system - Import exportNumber of results

64 ProductsCountries

- Germany (64)

- Berlin and region (1)

- Bonn, Düsseldorf and North Rhine and Westphalia (27)

- Frankfurt am Main and Hesse (2)

- Hannover and Lower Saxony (3)

- Kiel and Schleswig-Holstein (1)

- Leipzig and Saxony (1)

- Mainz and Rheinland-Pfalz (3)

- Munich, Nuremberg and Bavaria (8)

- Potsdam and Brandenburg (3)

- Stuttgart, Freiburg and Baden-Wurtemberg (15)

Company type

Category

- Bottling and filling - machinery and equipment (7)

- Electric motors and parts (7)

- Dosing pumps (5)

- Cylinders, pneumatic (3)

- Plastics - industrial machinery and equipment (3)

- Concrete mixers (2)

- Food industry - machinery and equipment (2)

- Petrol engines (2)

- Engines & Parts (1)

- Industrial valves, operating equipment (1)

- Chemical industry - machinery and equipment (1)

- Adjustment - machine tools (1)

- Automation - systems and equipment (1)

- Boilerwork (1)

- Cheese-making machinery (1)

- Construction machinery (1)

- Coupling, pneumatic (1)

- Dosing - machines and equipment (1)

- Driveshafts and micro-motors - electric (1)

- Electroheat - machines and equipment (1)