- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- valve system

Results for

Valve system - Import export

ELKON GMBH

Germany

These pumps have been designed according to the most difficult conditions and heavy work.They are high performance pumps with diesel engine and S Valve System. Both models can deliver concrete up to 100 meters vertically or 300 meters horizontally. Both ELKOPOMP S45 & ELKOPOMP S60 are equipped with axle and tires. Thus, it can be easily towed and transported to required points. Moreover, the concrete delivery pipes can be easily assembled and become ready to deliver concrete. The brand of the hydraulic control unit used in ELKON Trailer Type Concrete Pumps is BOSCH-REXROTH (Germany) and the system is an open-circuit hydraulic system. ELKON Trailer Type Concrete Pumps are equipped with high quality and chrome coated concrete delivery cylinders. The system can easily regulate itself with power regulation when it delivers the concrete to higher distance by means of hydraulic pump which has variable flow, power regulation and axial piston.

Request for a quote

ELKON GMBH

Germany

These pumps have been designed according to the most difficult conditions and heavy work.They are high performance pumps with diesel engine and S Valve System. Both models can deliver concrete up to 100 meters vertically or 300 meters horizontally. Both ELKOPOMP S45 & ELKOPOMP S60 are equipped with axle and tires. Thus, it can be easily towed and transported to required points. Moreover, the concrete delivery pipes can be easily assembled and become ready to deliver concrete. The brand of the hydraulic control unit used in ELKON Trailer Type Concrete Pumps is BOSCH-REXROTH (Germany) and the system is an open-circuit hydraulic system. ELKON Trailer Type Concrete Pumps are equipped with high quality and chrome coated concrete delivery cylinders. The system can easily regulate itself with power regulation when it delivers the concrete to higher distance by means of hydraulic pump which has variable flow, power regulation and axial piston.

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

TOPAZ differential valves are the ideal valve for water tanks in pressurised systems. The float valve with diaphragm offers a high flow rate of up to 200 l/min. Furthermore, an adjustable level control from 50 mm up to 2500 mm is possible. This minimises the number of start-stop operations of the pump system and ensures minimal pump operation.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Preformed silicone heaters are useful for diamters as small as 12 mm and up to 100 mm. Rounded silicone heaters are not possible with self-adhesive foil. Spiral Wrap Pre-Formed Silicone Rubber Heaters are suitable for tubes and flexible pipes and hoses with Ø 6,35 mm (1/4"). Spiral formed flex heaters can be used up to Ø 12 mm (the length of the stretchable silicone spiral wrap heater is reduced accordingly). The thickness of our spiral-wrapped silicone strip heaters is 2,2 mm. Also our gas and pump line heaters, most frequently used in the semi-conductor process, are shaped and pre-formed according to the object geometry to be heated. They are designed to regulate temperatures in order to prevent condensation in the line. Current applications here are Semi Conductors, Vacuum Chambers, Wafer Chucks, Valves, Exhaust & Pump Systems.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Swivel motors from this series are generally suitable when program sequences such as acceleration – travel – deceleration in open-loop or closed-loop controlled systems are determined via proportional or servo valves. The swivel motors in this series are often also suitable in combination with simple hydraulic circuits if the inertia forces occurring are small, e.g. when opening and closing emptying systems, actuating valves, placing and removing workpieces, swiveling load handling devices and much more. In order to provide our customers with the right drive for all areas of application, the HSG swivel motor is available in a total of 11 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Forged components for nuclear reactors, boiler systems, piping Valves are pivotal in various industrial contexts. Forged parts designed for nuclear reactors, boiler assemblies, pipeline construction, and safety valves are crucial elements in various industrial applications. Safety valves, typically pressure relief valves, stand out as paramount safety features within most systems. Their primary function is to safeguard pressurized vessels like steam boilers, reactor vessels, and pipelines from potentially hazardous pressure surges. In the event, that pressure exceeds safe limits, these valves release trapped gases, vapors, or liquids either into the atmosphere or into designated manifold systems. The West German drop forge KB Schmiedetechnik GmbH in Hagen (NRW) boasts decades of proficiency in crafting drop-forged components tailored for pressure applications compliant with the Pressure Equipment Directive (PED) and for nuclear facilities adhering to KTA, AVSD, and RCCM standards.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

pressure equipment: valves, boiler systems, piping PED 2014/68/EU, AD 2000-W0, ASME/ASTM, CNIM, Alstom, MHPS nuclear power/ atomic energy and plant construction KTA3201.1, KTA1401, AVS D 100/50, Siemens, EDF/Areva/RCC-M naval architecture/ shipbuilding and offshore/ ocean engineering American Bureau of Shipping (ABS) Bureau Veritas (BV) Det Norske Veritas (DNV) Lloyds Register (LR) Nippon Kaiji Kyokai (ClassNK)

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

KB Schmiedetechnik GmbH is a drop forge in West Germany, located between the historic “blade & metal region” Solingen and the “soccer city” Dortmund, specializing in small series production of safety-relevant closed die forgings from 200g to 130Kg unit weight of all steel grades and alloys according to following certifications and standards: pressure equipment: valves, boiler systems, piping PED 2014/68/EU, AD 2000-W0, ASME/ASTM, CNIM, Alstom, MHPS nuclear power/ atomic energy and plant construction KTA3201.1, KTA1401, AVS D 100/50, Siemens, EDF/Areva/RCC-M naval architecture/ shipbuilding and offshore/ ocean engineering, certified by • American Bureau of Shipping (ABS) • Bureau Veritas Marine & Offshore(BV) • Det Norske Veritas (DNV) • Lloyd´s Register (LR) • Nippon Kaiji Kyōkai (ClassNK) Examples: components and equipment like brackets, holders, chain links, hoists, lifting hooks, fasteners, pressure-bearing parts like valve bodies, pipe connections, gearwheels, ...

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

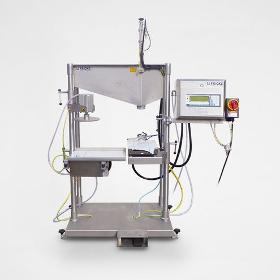

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of non-frothing liquids e.g. chemical liquids or oils. For the filling of open bunghole containers, such as canisters, bunghole drums or IBCs (Intermediate Bulk Container), directly on the pallet. Below bunghole filling coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ an almost froth-free, calibratable below bunghole filling of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ rapid changeover to other container sizes and changing products ■ simple operation by one person ■ Handling of empty containers (lifting heavy loads (filled containers)) not applicable

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers (min. Ø 150mm opening) just above fill level, e.g. canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above tevel filling just above the fill level with a ride-on valve of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fully automatic filling system with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. detergents/cleaning and car products, solvents, chemical liquids, mineral oils, glazes. For filling open bunghole containers, e.g. canisters. Below level filling coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via gravity or with the help of pumps. Direct connection via product hoses to the valve. The system offers you: ■ an almost foam-free, calibratable below level filling ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the ideal solution for small and medium filling orders ■ simple operation by one person ■ Modular design enables extension by many automatic systems

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or inks. For filling open containers, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. The System offers you: ■ calibratable above level filling ■ Thread-cutting, non-dripping filling valve ■ fast cleaning of the container (container and valve are cleaned in approx. 5 min using 1 l of solvent) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 10 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Our high pressure valves of the JB- series are specially designed for the metered spraying of liquids with a high proportion of solids. The completely dead space free construction leads the medium directly past the valve seat. Deposits and blockages, as known from many spraying systems, are a foreign word to us at Jerko. Compact design with low maintenance - these are the valves of the JB series! Pneumatically actuated, the valves achieve the shortest response times. 15 million switching cycles without repair have been confirmed by a customer. The best valves for spraying systems - already in use thousands of times!

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Cellular wheel sluices Cellular wheel sluices are used as discharge devices under filters, cyclones and silos, as well as for channelling materials into pneumatic conveying systems. In a special tested version, however, these can also be used at the same time for the explosive decoupling of complex plant systems in the sense of the ATEX regulations. Multi-cutter The multi-cutter is ideally suited for the chopping up of paper or plastic waste strips as well as veneer residues in extraction pipes. It works with a set of fast-rotating, but air-permeable blades. The connection diameter is DN 160 and the motor has a rated drive power of 0.75 KW. In order to be able to definitely assess the usability for the application, it is advisable to provide us with representative material samples. The assessment is also often proven by pilot plant trials. The advantage of this is that the degree of chopping can also be determined. ATEX non-return valves (EX) Non-return valves are passive decoupling elements in pipelines for preventing dust explosion effects from running in the opposite direction to the conveying direction. The non-return valves are type-tested protective systems in accordance with directive 94/9/EC, better known under the synonym ATEX 95. Function In normal operation, the top-mounted flap swims on the air stream in the housing of the non-return valve and in this way is held open. At a standstill the valve flap closes under its own weight and rests on the diagonally cut inflow pipe. If an explosion occurs behind the non-return valve, the air flow direction is reversed due to the increased counter-pressure. This causes the flap to close. The valve flap is additionally pressed against the inflow pipe by the pressure of the explosion, thus reliably sealing the pipeline against an explosion backdraught. These non-return valves function without external energy. The RSK and BPF-M series are available in the sizes DN 160, 200, 250, 280, 315, 355, 400, 450, 500, 560, 600, 630, 710, 800, 900 and 1,000. The two series differ in that they have different versions and application possibilities. The non-return valves, as type-tested protective systems, are sold through Brilex Gesellschaft für Explosionsschutz mbH, Hinterm Gallberg 15-17, D-59929 Brilon; www.brilex.de

Request for a quote

DALMINEX GMBH

Germany

Extensions for service and gate valves. Modular extension system with protective tube

Request for a quote

CETA TESTSYSTEME GMBH

Germany

The flow tester CETATEST 915 is used for flow testing with compressed air. It includes a measuring system consisting of laminar flow element (LFE) and differential pressure sensor In the direct test method the air, provided by the internal pressure regulator, flows through the measuring section before it enters the test part.In the indirect method, the measuring section is located in the outlet flow of the test part. Due to the special design of the measuring section a laminar ow is generated. The resulting pressure difference is directly proportional to the volume flow. With the optional electronic pressure regulator and four calibrations for up to four test pressures the application range is substantially expanded. Special versions: The CETATEST 915-G is a fully automatic flowmeter for the detection of leaking parts. Typical applications: 915: Testing of valves, vehicle exhaust systems, pipes, membranes, 915 G: Gas appliance industry, after-work jobs in the automotive industry

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quoteResults for

Valve system - Import exportNumber of results

27 ProductsCompany type

Category

- Bottling and filling - machinery and equipment (7)

- Electric motors and parts (7)

- Concrete mixers (2)

- Engines & Parts (1)

- Boilerwork (1)

- Electroheat - machines and equipment (1)

- Fittings, metal (1)

- Forges - machinery and installations (1)

- Forming - steels and metals (1)

- Nuclear power stations (1)

- Precision measuring instruments (1)