- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shafts

Results for

Shafts - Import export

IDG-DICHTUNGSTECHNIK GMBH

Germany

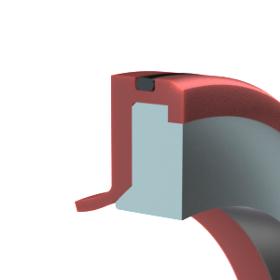

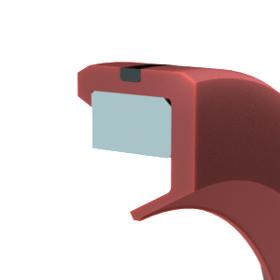

The standard version is universally usable, but in special cases the light version can offer additional advantages.The light version is suitable for tight installation conditions and is also easier to fit in nonsplit grooves.This version reduces the friction. The low compression reserve with a negative effect on large tolerances must be considered.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

The standard version is universally usable, but in special cases the light version can offer additional advantages. The light version is suitable for tight installation conditions and is also easier to fit in nonsplit grooves.This version reduces the friction. The low compression reserve with a negative effect on large tolerances must be considered.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Turned spindles, axles, shafts. Pistons for pneumatics, hydraulics, pumps. Ground, hardened, polished, chrome-plated.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

WELTE CARDAN-SERVICE GMBH

Germany

Welte Cardan-Service GmbH has developed into a leading company in the cardan shaft industry since 1972. Thanks to our many years of experience in the repair and overhaul of drive shafts and cardan shafts, we guarantee a rapid maintenance process with short delivery times, always optimised in line with our quality standards. Our maintenance service enables you to carry out the repair of almost any cardan shaft quickly.

Request for a quote

WELTE CARDAN-SERVICE GMBH

Germany

By cooperating with the leading Drive Shaft Manufacturers and service companies worldwide, we can cover almost any requirement. Our Drive Shaft warehouse with more than 20,000 positions offers a maximum of type diversity, from which almost every Drive Shaft can be manufactured.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Costconscious use of resources Every year in Germany, several million refrigeratorsare disposed of . With this enormous volume, refrigerators are certainly counted among the most important recycling products. After removing the chlorofluorocarbons, in a second step the housings are broken down into their individual components – iron, aluminium, copper and plastics. These are then made available again to industry as secondary raw materials. We equip our clients with extremely tough and hardwearing shredder disks and thus contribute to costconscious handling of resources.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

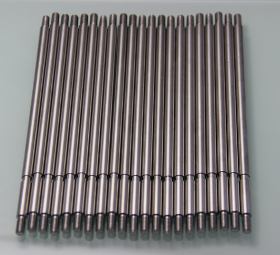

These are the parts used in mechanical shaft.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is the accessories used in valve.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Large machinery parts,Textile machine accessories.China cnc machining workpiece

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the stainless steel 316 turning part for shafts,produce by custom drawing,processing is more complicated.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These shaft made by stainless steel ,which were machining by the milling machine.Applied to specific mechanical parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Valve mechanical shaft fittings,CNC machining.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories used in valve fitting.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodized aluminum is a process that enhances the durability and resistance of aluminum by creating a protective oxide layer on its surface. This layer not only prevents corrosion and wear but also allows for custom surface coloration. Here are some key points about blue anodized aluminum: Color Options: Aluminum can accept a wide spectrum of anodized colors, including blue. Other available colors include pink, black, silver, gold, green, orange, red, and purple.Anodization serves multiple purposes: Corrosion Resistance: The protective oxide layer acts as a barrier against corrosion. Aesthetics: Anodized aluminum looks sleek and reflective due to the uniform oxide layer. Scratch Resistance: The tough anodic finish increases scratch resistance. Other Qualities: Anodization also affects wear resistance, heat dissipation, and adhesion. blue anodized aluminum combines aesthetics with functionality, making it a popular choice for various applications.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The stianless steel shafts, used in many fileds like construction manufacturing industry.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IGUS® GMBH

Germany

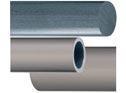

DryLin® R shafts and supported shafts - Technical data DryLin® R - AWMP Precision aluminum shaft, mm DryLin® R - AWMP DryLin® R - AWMU Supported aluminum shaft, mm DryLin® R - AWMU DryLin® R - SWM/EWM An steel or stainless steel precision shaft, mm DryLin® R - SWM/EWM DryLin® R - SWUM/EWUM Supported steel shaft orstainless steel shaft, mm DryLin® R - SWUM/EWUM DryLin® R - SWUMN/EWUMN Low supported steel shaft orstainless steel shaft, mm DryLin® R - SWUMN/EWUMN DryLin® R - EWUM Partially supported stainless steel shaft, mm DryLin® R - EWUM-Ø DryLin® R - CWM Carbon-fiber shaft, mm DryLin® R - CWM DryLin® R - AWMP Precision aluminum shaft, mm DryLin® R - AWMP DryLin® R - AWMU Supported aluminum shaft, mm DryLin® R - AWMU DryLin® R - SWM/EWM An steel or stainless steel precision shaft, mm DryLin® R - SWM/EWM DryLin® R - SWUM/EWUM Supported steel shaft orstainless steel shaft, mm DryLin® R - SWUM/EWUM DryLin® R - SWUMN/EWUMN Low supported steel shaft orstainless steel shaft, mm DryLin® R - SWUMN/EWUMN DryLin® R - EWUM Partially supported stainless steel shaft, mm DryLin® R - EWUM-Ø DryLin® R - CWM Carbon-fiber shaft, mm DryLin® R - CWM Aluminum Low weight Lower wear of the plain bearing Corrosion resistant Ideal in combination with liners made of iglidur® J/J 200 Delivered off the shelf Steel Low-priced standard High load capacity Application in dry area Hard chrome-plated also available Lower coefficient of friction against plastic bearing Stainless steel High corrosion-resistance High resistance to chemicals Ideal solution for the wet area V4A for extreme chemical intensive applications Female thread, axial male thread Pins Groove cut-in Spanner flat Female thread, radial Special machining All shafts can be individually machined. Please send us your drawing. We'll submit an offer to you in a short time. Shaft request

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Achieving precision material breakdown in just a single operation: that’s the proven capability of the Erdwich single-shaft shredder. How does it do it? The material is taken up by the cutting rotor and shredded repeatedly against the stator blade, using the tried-and-tested rotor/stator principle. This continues until the desired size has been achieved and the material can pass through the perforated screen underneath. The result is impressive: superior efficiency and optimum reliability for predefined fragment sizes. Choose the mature and highly economical technology of the ERDWICH single-shaft shredder for your application.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Continuous-process shredding of large quantities and volumes: that’s the world of the ERDWICH two-shaft shredder. The secret of its success is our ERDWICH rotor-blade cutting principle, honed to perfection over decades. Want to know more? The material is taken up by the barbed blade, pulled unceremoniously into the machine and then shredded between the blades on the two opposing shafts. Whatever the material – e.g. special waste, WEEE, metal swarf, electrical waste or bulky items – even hard to shred, large-volume materials stand no chance against these two mighty cutter shafts. Perfect results are even guaranteed from fibrous, moist, heat-sensitive, elastic and rubbery materials. And, thanks to its mode of operation as a slow-speed piece of equipment, the ERDWICH two-shaft shredder also features quiet and largely dust-free operation. You can rely on the power and the technology of the ERDWICH two-shaft shredder. Continuous-process shredding of large quantities and volumes:...

Request for a quote

IGUS® GMBH

Germany

iglidur® J260: ideal for plastic shafts Time and again the iglidur® J260 material proves its worth where the maximum service life and best friction coefficients are required under special application conditions - particularly in connection with plastic shafts! iglidur® J260 is available as cylindrical bearings and plain bearings with flange. Lubricants and maintenance-free Very good c.o.f. for low or medium loads Higher temperature resistance than iglidur® J Longer life time - even on polymer shafts

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

When processing electronic scrap, the aim is not merely to ensure the highest levels of process reliability and performance, but to salvage components such as capacitors and batteries intact where possible. Here, the the RM 1350/2 coarse shredder really struts its stuff: with the especially slow-running twin-shaft rotor/shredder system, the machine is especially resource-friendly and so ensures a large quota of intact capacitors and batteries. Two sizes of machine, with different shredder lengths and drive specifications are available to meet any challenge.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

The uniform shredding of coarse materials: that’s the speciality of the ERDWICH three-shaft shredder. ERDWICH has created the three-shaft design especially for these requirements. Entirely free of clogging and jamming – even with solid materials. Clever, huh? Absolutely: after all, the three cutter shafts and their individual sets of blades rotate at different speeds, so as to continuously pull in and precisely shred the feedstock material. If the material is too large, the sweeper shaft simply transfers the material to the lower cutter shafts for further size reduction. Again and again – until the material is the exact size as specified. Tirelessly, and with perfect reliability. Fragment size selection itself is achieved by the perforated screen substructure through which the material exits after the shredding process. Precise shredding of large and solid materials. That’s what ERDWICH does.

Request for a quoteHASPA GMBH

Germany

Anschluss WM Anschluss DIN Anschluss J Anschluss F Anschluss K Anschluss N Anschluss Direkt Anschluss Fo

Request for a quote

SONDERMANN PUMPEN + FILTER GMBH & CO. KG

Germany

without shaft seal streamlined spiral housing made of PP or ETFE volume flow of up to 320 l/min delivery head of up to 18m.WG back pull-out

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Applications at high speed and low pressure. With O‑ring as secondary seal for sealing in the groove base. Hygienic design without undercuts. No sump formation in front of the seal. Reduced heat buildup due to special lip design. Pressureactivated seal energization. The integrated wedge prevents the sealing lip turning inside out. Very long seal life due to high abrasion resistance. Material only generates low frictional force. Sealing lip does not stick to the mating surface even after prolonged shutdown

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

With internally protected sealing lip. With O‑ring for sealing in the groove base. For high peripheral speed and increased chemical resistance

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

High pressures at relatively low speed. For fluids over a wide viscosity range and for gases. Rotary unions at high pressure. Robot axes

Request for a quoteResults for

Shafts - Import exportNumber of results

319 ProductsCountries

- Germany (319)

- Bonn, Düsseldorf and North Rhine and Westphalia (112)

- Bremen and region (1)

- Frankfurt am Main and Hesse (10)

- Hannover and Lower Saxony (11)

- Mainz and Rheinland-Pfalz (28)

- Munich, Nuremberg and Bavaria (44)

- Potsdam and Brandenburg (29)

- Schwerin and Mecklenburg-Vorpommern (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (80)

- Weimar and Thuringia (3)

Company type

Category

- Moto-reducers (68)

- Clutches (24)

- Gears (21)

- Mechanical transmission systems and components (18)

- Sensors (16)

- Potentiometers (13)

- Mechanical transmission - components (12)

- Sealing rings (9)

- Pinions (9)

- Pumps (6)

- Monitoring and control equipment (6)

- Tidal power plants (6)

- Reamers (5)

- Grinding - machine tools (3)

- Automation - systems and equipment (3)

- Transmission elements (3)

- Water - production and distribution (3)

- Concrete mixers (2)

- Bearings, crankshaft (2)

- Electric motors and parts (2)