- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process development

Results for

Process development - Import export

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

Paints and coatings, sealing and insulating materials, coatings, chocolate masses, dairy products, personal care and many other products are produced on process systems from our company. The efficiency and effectiveness of your manufacturing processes can be significantly increased with the help of individually built process plants. Customized process plants are used by our customers worldwide. Container systems, which can be used flexibly at different locations, are available as well as our skidded units, which are completely frame-mounted and automated production units. Recipe control, visualization, weighing, measurement and control technology, containers and piping, CIP systems - all plants are completely assembled in our factory. After a test run under production conditions they are accepted by you. Our technicians are available to you on site for installation, commissioning and service.

Request for a quote

COLORPLASTICCHEMIE ALBERT SCHLEBERGER GMBH

Germany

The new alternative to amorphous PET pellets: In an innovative process developed by cpc, the material is directly post-crystallised. In this way, we are continuing the development from discontinuous crystallisation to underwater strand pelletisation and underwater pelletisation to direct post-crystallisation.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Special purpose machines are our specialty. We are able to adapt our standard machines to your needs within a short time or to develop and build completely new machines for your application. Our extensive know-how allows us to accompany you from process development through the design and detailed construction of a suitable machine to measurement, commissioning and the start of production in your plant. In addition, even maintenance or product adjustments if necessary.

Request for a quote

B + B THERMO-TECHNIK GMBH

Germany

The punctual measuring infrared thermometers are especially suited for precise controlling of industrial production processes, in the research and development and for controlling the function of various devices and plants.

Request for a quote

BORSIG GMBH

Germany

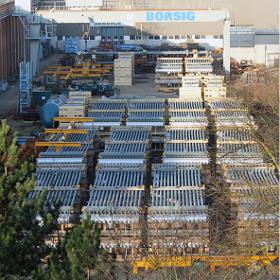

Reducing energy, saving resources and safe processing have high priority in the chemical and petrochemical industry today. Our advanced liquid separation technologies are targeted to treat hydrocarbon based or solvent containing process streams and provide valuable tools for process intensification. Typically organic liquid streams are processed by conventional thermal unit operations that consume high amounts of energy, operate at high temperatures and/or require additional chemicals for efficient separation. Our membrane based solutions offer potent alternatives or additions for new processes and a valuable tool for the retrofit of existing unit operations. Our product range: - BORSIG Organic solvent nanofiltration - BORSIG Pervaporation - BORSIG Process development services

Request for a quote

EMBRO GMBH

Germany

When it comes to seat heaters, we at Embro think first and foremost of the textile processors of vehicle seats. Because our textile heating elements are in great demand in the automotive industry. They are easy to process, flexible, and kink-resistant. The heat output is individually adapted to the customer’s requirements in the development process and suitably distributed and laid out on the desired surface (wire laying). With the increasing number of electric vehicles being produced, the demand for further heating solutions for the interior area is also rising. Embro heating mats heat the seats and interior via heating elements in the center and side armrests and trim parts. As a developer or engineer in the automotive sector do you need a specific heating element for a product? We are looking forward to your ideas!

Request for a quote

INGENERIC GMBH

Germany

The first approach for the development of new processes and the research of scientific effects is the application of standardized laser systems. When the requirements on scientific research advance, they equally rise with regard to the laser systems. For optimum results in scientific research and development, diode lasers with very precise specifications are indispensable. Operating and monitoring the system with defined and fixed parameters such as the power distribution and wavelength is essential for the accurate collection and evaluation of data and will lead to reliable results. Provisioning an outright laser system will further enable scientists to actually focus on their actual research. As complete solution the system can furthermore be directly integrated into the security system, providing a safe operation for your team of experts.

Request for a quote

KULLEN-KOTI GMBH

Germany

Kullen Koti End, Cup and Bevel brushes give a gleaming finish to oxidised or coated metal surfaces. They are all-rounders in drilling machines, on angle grinders and in machining centres, performing such tasks as removing paint, scale and corrosion. They are also ideal for use in places which are difficult to get at, and were specially developed for the processing of edges and corners.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP® Welded Tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP® and can be constructed individually in diameter in volumes of 50 to 10,000 m³ according to the application. LIPP® offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to highalloy stainless steels. The automated process meets the highest quality standards. LIPP® Welded Storage Tanks can be produced within a short time, either on site in the open air or inside a building.

Request for a quote

ORBIS EUROPE

Germany

The ORBIS IonPak® is a UN certified plastic container that is designed to transport solid dangerous goods (e.g. UN3480). The solution consists of a durable standard container with customised inner packaging. The lithium battery shipping boxes are suitable for non-certified batteries, prototypes, battery cells, battery modules and batteries in equipment. For increased part protection, the shock absorbing interior packaging is adapted to the customer’s product and supply chain. ORBIS’ lithium-ion battery packaging utilises standard footprints designed to interface with customers’ existing supply chains, e.g. 1200 x 1000 mm. - Certified solutions according RID/ADR - Customer-specific dunnage development - Heavy-duty solution for heavy batteries - Comprehensive product protection - Reusable and recyclable - Different footprints available ORBIS Europe supports you through the entire process – from development to certification of your packaging solution.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

FLOTTWEG SE

Germany

Reliability isn't just a keyword for Flottweg – it expresses the company's philosophy. We want our customers to get results with Flottweg that can't be beat. That requires reliable machines, reliable service, and staff whose passion for perfection shows throughout the manufacturing process. The newly developed Flottweg Z2E brings us a huge step towards that goal. This decanter centrifuge is flexible, maintenance-friendly, and powerful. With its easy-to-open cover, Flottweg makes access to the main components quick and easy, with no need for lifting equipment. Together with another feature – the super deep pond – the Flottweg Z2E highlights the know-how that has gone into this decanter. Top flexibility and quality characterize the Flottweg Z2E, which has been Engineered For Your Success.

Request for a quote

BORSIG GMBH

Germany

Transfer Line Exchangers (tunnelflow and linear quench coolers) from BORSIG are used in plants producing ethylene, an important starting material for plastics manufacturing. In these ethylene plants our transfer line exchangers are rapidly cooling down the so-called cracked gas in order to obtain the optimum yield of ethylene. BORSIG Transfer Line Exchangers are the result of more than 50 years experience and about 7,500 units have been supplied worldwide between 1965. BORSIG Process Heat Exchanger GmbH has developed two design types of quench coolers, reflecting the customer`s plant concept: 1. "Tunnelflow" transfer line exchangers (shell & tube design) 2. BORSIG "Linear" transfer line exchangers (double-pipe design)

Request for a quote

CIC - KLAUS CZERWONKA

Germany

We know the challenges that new technologies in e-mobility (BEV) entail for established players in the transition from combustion engines to New Energy Vehicles as well as for start-ups in the process of structural development in daily practice. We would be happy to take over for you: quality assurance rework conversions field actions component qualification startup protection Congestion management production management and many other tasks that can be completed quickly and flexibly

Request for a quote

TEPROSA GMBH

Germany

We offer laser direct structuring (LPKF-LDS process) for the production of 3D-MID (so-called three-dimensional circuit carriers) as a service in Magdeburg. 3D-MID stands for Mechatronic Integrated Device (or Molded Interconnected Devices). The MID technology makes it possible to use three-dimensional plastic parts as circuit carriers for electronic or mechatronic assemblies. The LPKF-LDS process is one of the technologically leading and at the same time most economically interesting process for the production of 3D-MID. The LPKF LDS process represents the central process step. The process was developed and patented by the company LPKF Laser & Electronics AG in Hanover.

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

State-of-the-art crane systems move the heaviest construction and production components on construction sites and in production halls. MACK solutions are available to help you make the most of your potential! Cranes and hoists are mostly used in demanding situations, where space is limited and conditions are very hot or cold, very damp or very dry. This means: Even under the toughest indoor or outdoor conditions, extension arms and grippers have to be reliably supplied with energy and data in order to carry our their lifting operations without any disturbances. With our carbon brush components we support you as system suppliers, finding ‘your’ solution, no matter where you are in the development process. Design, manufacturing, tool making and assembly – all from a single provider. And done in-house. Applications in crane technology Our solutions Our services

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

Our products are unseen aides installed in many electric machines and motors: from huge plants to compact hand-held devices. Are you looking for a entirely specialised solution for current and data transmission? We produce the right carbon brushes and brush holders for the broad range of applications which characterises the field of electrical and plant engineering. This includes filling and packaging machinery, waste water treatment plants or revolving door systems, just as much as the manual electrical appliances which provide professional and hobby craft workers with reliable service. And these are a just a few examples. As we are system suppliers, you can be absolutely sure: MACK supports you throughout the entire development process. MACK supplies first-class OEM quality and durable replacement parts from in-house production. MACK makes your ideas come true!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

IN STEEL AND STAINLESS STEEL FROM 50 – 10,000 M3 LIPP welded storage tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP and can be constructed with steplessly adjustable volumes of 50 to 10,000 m³ according to the application. LIPP offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to high alloy stainless steels. The automated process meets the highest quality standards. LIPP storage tanks can be produced within a very short time, either on site in the open air or inside a building. The special circumferential profile ensures additional stability compared to conventional processes. KEY BENEFITS Three different welding processes based on the LIPP system and adjusted to the application

Request for a quote

DIETZ GMBH

Germany

Customised production to your specifications: We work very closely with you when it comes to producing torsion springs. Torsion springs are produced in accordance with your specifications based on drawings, prototypes or sketches. We manage the development process of the spring until it is ready for serial production. We produce torsion springs with wire diameters of 0.20 to 4.00 mm, with or without torque testing. Wire coatings: Galvanised, ZnAl-plated, Red-coated, Nickel-plated, Polished nickel, Phosphated, Brass-plated,Silver-plated.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

DE-BURRERS Specially developed for processing contours on CNC machines. To de-burr and chamfer metals and plastics. The de-burrers are also suitable for hard machining. Deburrer for contouring. Designed for use on CNC machines, especially for contour machining. For deburring and chamfering of metals and plastics. The de-burrers are also suitable for hard machining. Stocked by default is a point angle of 90 °. 4 - 6 mm de-burrer with 4 cutting edges, from 8 mm with 5 cutting edges.

Request for a quote

BORSIG GMBH

Germany

BORSIG offers attractive process solutions for various gas separation applications in the fields of oil and gas production or refinery and process technology, such as BORSIG Hydrogen separation and BORSIG Fuel gas conditioning. This covers the treatment of gas streams for conditioning raw gas flows, recovery of specific components and the improvement of product quality to comply with customer gas specifications. Process concepts can be developed in addition to existing processes or as an alternative to conventional process solutions.

Request for a quote

SPIES PACKAGING / SPIES KUNSTSTOFFE GMBH

Germany

With the technology of the SPIES MM we have developed an innovative process to be able to decorate curved products as well. The state-of-the-art in-mold labeling (IML) process allows us to produce curved shapes as 1-material packaging and consequently 100% recyclable. Your desired article geometry can be developed individually.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

If companies want to decide on a future-proof bus technology, comprehensive advice will be needed in the early stages of the development process. We mostly start with a MicroControl workshop or webinar which will then be followed by support and advice in the research and development stage. If the decision has been made for CANopen classic or FD, the MicroControl experts will work in close liaison with the customer to realise hardware and software for the desired application. In a following step, a prototype will be developed and manufactured – either by the customer or MicroControl. In the conceptual stage, the required technical specifications of the customer’s application are checked continually. With more than 25 years of experience in project management in a variety of industries, we will be your reliable partner for future solutions.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

New employees are first introduced to TIG welding in a basic training lasting several months. Only then are the first products manufactured for customers, whereby the following topics are handled in a multi-year development process, which includes the welding test for the tube welder CrNi relatively early: Material requisition Additional materials Gas protection Interpass temperature and welding temperature Maximum material temperature during welding Cleaning the weld seam Welding distortion Mechanical seam load

Request for a quote

BDSENSORS GMBH

Germany

The electronic pressure switch DS 400P is the successful combination of — intelligent pressure switch — digital display and has been developed for process industry; especially for food industry and pharmacy. As standard the DS 400P offers a PNP contact and a rotable display module with 4-digit LED display. Optional versions like e.g. an intrinsically safe version, max. 2 contacts and an analogue output complete the profile. Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 40 bar — accuracy: 0.35 % (opt. 0.25 %) FSO — 1 or 2 independent PNP contacts, freely configurable — indication of measured values on a 4-digit LED display — rotatable and configurable display module — hygienic process connections with flush stainless steel diaphragm Optional Features: — IS-version Ex ia = intrinsically safe for gases

Request for a quote

BDSENSORS GMBH

Germany

The precision pressure transmitter DMP 331Pi demonstrates the further development of well-tried industrial pressure transmitter DMP 331P. The signal from the specially designed piezoresistive stainless steel sensor is processed by the newly developed digital electronic system, performing thus an active compensation of sensor-specific deviations such as hysteresis, thermal errors and non-linearity. The temperature field of application of -40 ... 125 °C can be extended by the integration of a cooling element up to 300 °C. Features: — nominal pressure: 0 ... 400 mbar to 0 ... 40 bar — accuracy: 0.1 % FSO — excellent temperature response 0.04 % FSO / 10K (≤ 0.04 % FSO / 10K) — hygenic version — vacuum resistant — processing of the sensor signal using digital electronics Optional Features: — IS-Version Ex ia = intrinsically safe for gases and dusts

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The laboratory vacuum shovel dryer DRUVATHERM® is a system provides reliable scale-up to production scales in the context of product and process development and can likewise be used for small batch production too. The Lödige laboratory vacuum shovel dryer DRUVATHERM® is a horizontal, batch vacuum dryer with a frequency-controlled mixing tool. This mixer consisting of mixing elements adapted to the process and arranged on a shaft according to a specific system - is installed in a cylindrical mixing drum equipped with a temperature control jacket. Rotation of the mixing unit generates a three-dimensional product movement, in which all of the product is constantly in motion. The contact frequency of particles with the heat exchange surface leads to shorter drying times. The chopper rotating at high speeds fitted to the side of the mixing drum is used to disperse the product . This leads to a significant increase in drying capacity and prevents moisture and temperature gradients.

Request for a quote

STRUBL GMBH & CO. KG KUNSTSTOFFVERPACKUNGEN

Germany

Our construction-kit realizes custom-designed packaging products films and bags produced in a low particle cleanroom atmosphere lots of specialities Qualified process development enables quality, efficiency and rapid prototyping together with our customers we settle an individual order fullfilment process including quality- and logistic management

Request for a quote

NOREVO GMBH

Germany

Our low bac honey (low bacteria = germ-reduced) has been specially developed for microbiologically demanding and sensitive products. Our internally developed thermal process reduces germs by heating the honey.

Request for a quoteResults for

Process development - Import exportNumber of results

60 ProductsCountries

- Germany (60)

- Berlin and region (3)

- Bonn, Düsseldorf and North Rhine and Westphalia (25)

- Frankfurt am Main and Hesse (3)

- Hamburg and region (1)

- Hannover and Lower Saxony (2)

- Leipzig and Saxony (1)

- Magdeburg and Saxony-Anhalt (1)

- Munich, Nuremberg and Bavaria (8)

- Stuttgart, Freiburg and Baden-Wurtemberg (15)

- Weimar and Thuringia (1)

Company type

Category

- Dustbins, waste bins (9)

- Medical laboratories (5)

- Domestic waste treatment (4)

- Gas detectors (4)

- Import-export - mechanical engineering (3)

- Measurement and regulation equipment and instruments - pressure (2)

- Pharmaceutical industry - machinery and equipment (1)

- Bearings - ball, needle and roller (1)

- Boxes, plastic (1)

- Custom packaging (1)

- Electric and electronic components - machines for manufacturing (1)

- Electrical & Electronic Components (1)

- Electronic components (1)

- Electronic data processing - microcomputers (1)

- Filters, liquid (1)

- Gas - production and distribution (1)

- Glass hollowware, coloured (1)

- Heat exchangers (1)

- Helical springs (1)

- High-vacuum photo-cells (1)