- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine spindles

Results for

Machine spindles - Import export

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Decades of experience in development and top precision in manufacturing GMN machine spindles with certification under national and international quality standards secures permanent outstanding characteristics in regards to bearings, Speed suitability and machining. The options for standardized series offer the best spindle solutions for nearly all applications. A variety of successfully-implemented GMN special designs confirms that we can develop outstanding, high-performance products to assist our customers in extraordinary construction projects.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HS, HSX, HV-X and UHS series are irreplaceable for grinding work. Whether you must work with holes or frames, with these spindles you always make the right choice. The HV-X and HV-P series are optionally available with a rotational angle sensor, and therefore outstandingly suitable for 4Q operation. The types in the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and furthermore suited for milling and drilling applications.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

The current series TSA, TSI, TSP, TSAV,of the external-driven GMN tool spindles follow the first grinding spindles made by GMN in the 1930s. Then and today, we provide simple, but robust and functional spindles that reliably fulfill their tasks. Depending upon the customer’s tool selection, spindles are available with various tool holders.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and suited for milling and drilling applications.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HC, HCS, UHS, HCT series are an essential component of highly-effective machining of various materials. Whether aluminum, steel or titanium, these spindles are optimally designed for all machining tasks which require performance, torque and speed. Using an oil-air or grease permanent lubrication, the spindle bearings operate in a secure fashion.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-performance spindles with an integrated motor are designed for those applications and relevant installation situations in close collaboration with our customers. They are available as needed with a synchronous or asynchronous motor, for manual - HGS series - or automatic tool change - HGC, HGT series - and with oil-air or grease lubrication. Additional options are, for example, an AE sensor, vibration sensor or an automatic balancing system.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

GMN high-speed spindles of the HS, HSX, HV-X and UHS series are irreplaceable for grinding work. Whether you must work with holes or frames, with these spindles you always make the right choice. The HV-X and HV-P series are optionally available with a rotational angle sensor, and therefore outstandingly suitable for 4Q operation. The types in the HV-P, HSP and HSP..g series are equipped with an HSK-C holder and furthermore suited for milling and drilling applications. GMN high-speed spindles of the HC, HCS, UHS, HCT series are an essential component of highly-effective machining of various materials. Whether aluminum, steel or titanium, these spindles are optimally designed for all machining tasks which require performance, torque and speed. Using an oil-air or grease permanent lubrication, the spindle bearings operate in a secure fashion.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Powerful, long-lived, precise: GMN motor spindles for manual or automatic tool change stand for quality and efficiency, and are well-suited to your grinding, milling, drilling or special applications.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Driven tools form a further core area of EWS. More than 8,000 different tools are available at short notice. In addition to standard products like axial and angular heads, EWS offers swivel units, slot broaching tools, multiform tools and multi-spindle machines. There is just no limit. The tool clamping systems range from the classic collet chuck holder to Weldon and hydro extension to Capto, KM, ABS and HSK. The applications range from classic CNC lathes to highly complex turning milling centers. The rapid change system EWS-Varia has set a standard for a flexible modular system. With its safe handling and short change-over times, EWS-Varia ranks among the most successful systems in the market. This was impressively confirmed by the Innovation Award awarded by the German state of Baden-Württemberg in 2006. "Made in Germany" is of course guaranteed by EWS also for these tool systems.

Request for a quote

SAMSYS GMBH

Germany

Unloading machine Multi-3000 remove The Multi-3000 remove is an electro-pneumatically controlled automatic unloading machine. It is the ideal complement to the bar feeder Multi 3000 or the Multi 3000SL. With the Multi 3000 remove it is possible to unload finished parts from sub- or main spindle. The bars are unloaded by unloading tube, pneumatic gripper or also by collet chuck. After unloading, the bars are placed on a prism. From the prism the parts are transported to a deposit. A light barrier monitors the unloading process. The coating of the depositing surfaces enables a particularly gentle handling of the finished parts. Even parts such as piston bars can be unloaded without a scratch. The unloading tube is made of POM material. This also ensures gentle handling. Loading can be done via the main spindle and unloading via the sub spindle. It is also possible to load via the sub spindle and unload via the main spindle. Compatible with almost all types of lathes.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

With more than ten GMN authorized GMN service centers throughout the world, we offer our customers over 80 years of experience in the development and production of machine spindles. Our extensive service network ensures that we can offer expert advice as well as long term maintenance and quick repairs. If the spindle function is compromised, GMN service technicians are on-site quickly to ensure that our customers maintain maximum productivity. Equipped with the latest technology, GMN repair service guarantees a detailed cause analysis and professional service – worldwide.

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

rotating spindle machine for coating rotationally symmetrical parts

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

rotating spindle coating machine for larger quantities or longer process times

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of open pinion gears which are highly subject to wearing due to corrosion and continuous soiling, e.g. on construction machines, spindle presses, crushers, mills, windlasses, rubbish disposal devices, ship´s lifting jaws or water structures Wire cables subject to outdoor weathering, e.g. on crane systems, lifts and aerial tramways, ship´s and offshore equipment for diverse types of sealing lubrication, including of coarse chains and chain transporters Advantages and benefits Highly effective due to outstanding wetting and lubricating properties Decreased friction and wear, and therefore reduction of necessary repair times Economical due to thrifty consumption as a result of small application quantities and time-saving use due to advantageous spray form Dry, elastic film with high adhesive strength prevents adhesion of dust and dirt Waterproof and has good corrosion protection properties

Request for a quote

MICRO-EPSILON

Germany

The SGS (Spindle Growth System) 4701 displacement measuring system is developed for high speed milling machine applications. Due to high machining speeds and the heat generated, the linear thermal expansion of the precision machine tool spindle needs to be compensated for in order to keep the tool in a defined position at all times. The SGS sensor measures the expansion of the spindle caused by thermal and centrifugal force. The measurement takes places typically on the labyrinth-ring. As well as the linear expansion, the temperature of the sensor is detected and output.These measurement values are fed into the CNC machine tool as correction values, compensating for any positioning errors.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

UP milled parts are components that due to their geometric shape can only be produced with 4- or 5-axis machines with high-frequency spindle. The MM machines, developed by LT Ultra, make it possible to produce the parts economically and quickly.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper’s high-performance FLEXA flat belts are made of fully synthetic polyamide or polyester fabric and polyamide foil, with or without a suitable adhesion coating made of nitrile-butadiene rubber, depending on the wide range of possible power transmission and conveying applications. Fitted with a polyamide or polyester reinforcement With a one-sided or two-sided coating of nitrile-butadiene rubber, highly resistant to abrasion and wear Different surface structures FLEXA belts can be used as: Power transmission belts Folder-gluer belts Machine belts Tangential belts Spindle belts Properties + Suitable for a large temperature range + High resistance to abrasion + Very good dynamic properties + Resistant to oils and acids + Outstanding anti-static properties of black NBR - Gets brittle when exposed to UV light and ozone (only for limited outside use) - Processing is work and energy intensive (vulcanization, hardening)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRESSTA EISELE GMBH

Germany

4 axis CNC floor-type vertical spindle machining center. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of aluminium, PVC and steel sections. The work pieces are held by means of 4 pneumatic vices on the mobile beam, that can be positioned on any angle between +125° and -125°. The rotation is directly managed by the control cycle. It offers a high programming functional capacity by using a three-dimensional graphics software. Electro-welded base designed to grant maximum rigidity and functional capacity of use. The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The vices slide on ball recirculation screws, and can be positioned manually by referring to a mm-scale and a laser pointer. By using the disc cutter it is possible to carry out end-milling operations on both the ends of the work piece (end-milling cycle). Milling operations can be performed with...

Request for a quote

PRESSTA EISELE GMBH

Germany

4 axis CNC floor type vertical spindle machining centre. 4 axis (X, Y, Z, A) managed by CNC. By means of dedicated tools it’s suitable for working on 5 sides of profiles. Suitable for processing on ANY surfaces, generated by the rotation of the spindle axis (side by side at Y axes) on the positions within 180° (± 90°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. The working table can be divided in two areas so to get two separate working stations. Using a disk cutter, it is possible to work on both sides at the end of the profile (end milling cycle). Milling operations can be performed with linear and circular interpolation of the axes X-Y-Z. The hinging length stop are pneumatically managed. The electric spindle is suitable for quick tool holder change. The tool magazine is mounted on the mobil upright. The tool change can be carried out into any position...

Request for a quote

PRESSTA EISELE GMBH

Germany

5 axis CNC floor type vertical spindle machining center. 5 axis (X, Y, Z, C, A) managed by CNC. Suitable for milling, drilling, tapping and cutting on the 5 sides of aluminum, PVC, steel and light alloys profiles; thanks to the 5 axis interpolation, the machine is able to execute composite cuts. The X or longitudinal axis, the Y or transversal axis and the Z or vertical axis belong to the tool movement. They can be interpolated in linear and circular way on 3-dimension geometrical planes, belonging to X-Y-Z. The C axis can be turned and positioned on all angles within 440° (± 220°); the A axis can be tilted and positioned on all angles within 250° (± 125°). The axis slide on precision profile guides with ball recirculation and are driven by motors operated with digital systems. The locking clamps slide on guide rail. By using the disc cutter it is possible to carry out end-milling operations on both the ends of the work piece (end-milling cycle). Milling operations can be...

Request for a quote

SAMSYS GMBH

Germany

The basis of short bar loader Multi 3000SL was developed in Switzerland. It was specially designed for turning machine types with a large distance between machine cover and spindle end. The bar feeder is supplied as standard with a Z-axis sliding unit to ensure free access to the Spindle Liner. This makes it easy to change the spindle insert tube. The Bar Loading Magazine is manufactured in Germany with first-class materials and components. The MULTI-3000SL guarantees long-term reliability. It impresses with its service and environmentally friendly design. It is also a fully electric and servo-controlled magazine. Due to the easy access to all parts it is extremely user-friendly. It is very simple to understand and therefore easy to operate. Due to the well thought-out design, set-up and changeover is possible within 2-5 minutes. The patented lifting mechanism guarantees an impact-free and fast loading cycle.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

MULTISPINDLE DEEP DRILLING MACHINES AND SPECIAL DEEP DRILLING AND MILLING CENTRES – TBM roto, TBM flex, TBM mono TBM roto - Machining of rotationally symmetrical workpieces - Used in the automotive industry and medical technology, among others - Customized solutions, automation, handling, workpiece clamping, workpiece cleaning, etc. - Durable machines for parts with maximum precision 24/7 - Optimized accessibility for maintenance and service TBM flex - For individual and series production - Skiving and roller burnishing possible - Machining of forklift forks, telescopic forks, aircraft landing gear parts, special screws, special cylinders TBM mono - Very small drilling diameter with large drilling depth - Crane loading possible - Service and maintenance-optimized accessibility - Short set-up times

Request for a quote

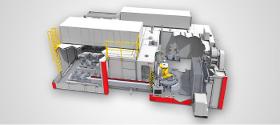

SAMAG MACHINE TOOLS GMBH

Germany

CUSTOMIZED SOLUTIONS READY TO USE! – The MFZ series offers endless solutions! INNOVATION THOUGHT THROUGH TO THE END! - Modularity in components takes you to the finish line. - Universal machine with 2, 3, or 4 spindles WHETHER DEALING WITH COMPLEX WORKPIECE DIMENSIONS OR IN SEARCH OF THE OPTIMAL QUANTITY SOLUTION WITH MINIMAL MACHINE INVESTMENT – We have consistently evolved our proven machine tool technology. - Extreme adaptability in dimension, material, accuracy, and capacity of your machining task DESIGNED IN THE PROVEN SAMAG CONSTRUCTION, BUT PERFECTED IN MANY DETAILS! – The modular design has significantly expanded the range of workpiece dimensions. - Unique modular system with optional width scaling and thereby correction possibilities in X-, Y-, and Z-direction LOWEST COST PER PART. – MFZ machines operate particularly efficiently, quickly, and dynamically. - Energy, lubricant, and compressed air consumption are significantly reduced

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles in one clamping Machining time on 3-spindle solution 97s Right and left workpieces are produced in the same machine

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles Tool monitoring for all tools takes place parallel to production time

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

3 or 4 spindle machining Complete processing on MFZ Processing time less than 55s per workpiece

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

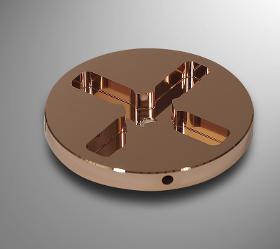

The automatic feeding of tools from the tool magazine to the machining spindle is implemented in modern machining centers with the aid of a tool changer. At the same time, this device is used to return tools to the tool magazine. Reducing non-productive times is an important criterion for increasing the efficiency of machining centers. The chip-to-chip time is directly positively influenced by a fast tool change, i.e. a short tool change time.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

Universal centring microscope to set up tool machines (for example milling or drilling machines). The edges of a workpiece can be positioned, rotary stages can be centered or machine spindles can be aligned. The centring microscope is fixed in the machine instead of the tool. the image is true erect and with high contrast the eyepiece has a graticule with crosshair and concentric circles LEDs are used for the incident light 5 µm centring accuracy can be achieved DIN 2080-A 40 (short taper) standard fixture

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles OP 10 with 4 part clamping on workpiece carrier unit OP 20 with 4 workpieces on 2 rotary tables (5-axis machining

Request for a quoteResults for

Machine spindles - Import exportNumber of results

86 ProductsCountries

Company type

Category

- Mechanical engineering - custom work (17)

- Machine tools, metal machining - parts and accessories (7)

- Woodworking - machinery and equipment (6)

- Milling - machine tools (2)

- Drilling machinery (2)

- Silicones (2)

- Varnishing equipment (2)

- Machine tools - metal machining (1)

- Turning - steels and metals (1)

- Metals - Machines & Equipment (1)

- Tools & Hardware (1)

- Adjustment - machine tools (1)

- Automation - systems and equipment (1)

- Conveyor belts (1)

- Electric motors and parts (1)

- Measurement - Equipment & Instruments (1)

- Plate glass and mirrors (1)

- Sensors (1)

- Testing equipment (1)