- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine spindles

Results for

Machine spindles - Import export

EWS WEIGELE GMBH & CO. KG

Germany

Driven tools form a further core area of EWS. More than 8,000 different tools are available at short notice. In addition to standard products like axial and angular heads, EWS offers swivel units, slot broaching tools, multiform tools and multi-spindle machines. There is just no limit. The tool clamping systems range from the classic collet chuck holder to Weldon and hydro extension to Capto, KM, ABS and HSK. The applications range from classic CNC lathes to highly complex turning milling centers. The rapid change system EWS-Varia has set a standard for a flexible modular system. With its safe handling and short change-over times, EWS-Varia ranks among the most successful systems in the market. This was impressively confirmed by the Innovation Award awarded by the German state of Baden-Württemberg in 2006. "Made in Germany" is of course guaranteed by EWS also for these tool systems.

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

rotating spindle machine for coating rotationally symmetrical parts

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

rotating spindle coating machine for larger quantities or longer process times

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

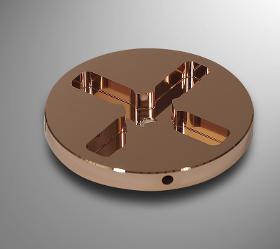

UP milled parts are components that due to their geometric shape can only be produced with 4- or 5-axis machines with high-frequency spindle. The MM machines, developed by LT Ultra, make it possible to produce the parts economically and quickly.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper’s high-performance FLEXA flat belts are made of fully synthetic polyamide or polyester fabric and polyamide foil, with or without a suitable adhesion coating made of nitrile-butadiene rubber, depending on the wide range of possible power transmission and conveying applications. Fitted with a polyamide or polyester reinforcement With a one-sided or two-sided coating of nitrile-butadiene rubber, highly resistant to abrasion and wear Different surface structures FLEXA belts can be used as: Power transmission belts Folder-gluer belts Machine belts Tangential belts Spindle belts Properties + Suitable for a large temperature range + High resistance to abrasion + Very good dynamic properties + Resistant to oils and acids + Outstanding anti-static properties of black NBR - Gets brittle when exposed to UV light and ozone (only for limited outside use) - Processing is work and energy intensive (vulcanization, hardening)

Request for a quote

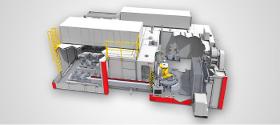

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

Designed for machining cubic parts up to 100 kg in weight, the C12 works in the most diverse applications compactly, precisely and dynamically. The C 12 is more than a match for larger models. Aside from its compact size, the main focus is on HERMLE's core competences precision, durability and dynamics. Designed as a 5-axis machining centre featuring the different spindle speeds and different interfaces, the ideal speed is available for almost every area of application. The C 12 can be equipped with two-piece ore compact spindles. All tool spindles can be replaced quickly and easily in case of failure. Thanks to the respective HERMLE set-ups, the C 12 also meets the ever increasing requirements placed on speed and precision. The C 12 machining centre additionally provides extensive options for more intricate applications.

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Gripping technology from AMF: Inexpensive, efficient, safe High gripping force, Suitable for a diverse range of workpieces, Overload protection prevents damage, Combined application of different gripper types. The pneumatically driven gripper is available in different designs. The integrated self-resetting counterbalance elements facilitate the exact positioning of the unmachined parts or pre-cast parts and relieve the machine spindles. Our product range for low-cost automation with three different gripper elements is complete and even more flexible.

Request for a quote

FISCHER FORTUNA GMBH

Germany

Compact asynchronous motor spindle for micron machining with speed up to 50,000 rpm. Due to the bearing arrangement the PRECISE SC80 can be used for light milling and drilling application and also for grinding application. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals.

Request for a quote

FISCHER FORTUNA GMBH

Germany

Compact motor spindle for micron machining with speed up to 60,000 rpm. Due to the bearing arrangement the PRECISE SC3163 can be used for light milling and drilling application and also for grinding application. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals.

Request for a quote

FISCHER FORTUNA GMBH

Germany

Compact motor spindle for micron machining with speed up to 80,000 rpm. Due to the bearing arrangement the PRECISE SC2063 can be used for light milling and drilling application. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals.

Request for a quote

FISCHER FORTUNA GMBH

Germany

Compact motor spindle for micron machining with speed up to 160,000 rpm. Due to the bearing arrangement the PRECISE SC1060 OA can be used for light milling and drilling application and also for grinding application. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals.

Request for a quote

FISCHER FORTUNA GMBH

Germany

Compact asynchronous motor spindle for micron machining with speed up to 50,000 rpm. Due to the bearing arrangement the ESC 3043 can be used for light milling and drilling application. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals.

Request for a quote

SNK GMBH

Germany

◆High-rigidity continuous 5-axis spindle head ・This machine is equipped with a highly rigid continuous 5-axis spindle head which enables the continuous machining of high-strength materials such as iron, titanium, and difficult-to-cut materials without using axis clamping mechanism ・High-rigidity square 450 mm ram and unique high torque rotating structure gives max. rotating torque of 6600 N・m for B and C axis

Request for a quote

BRITSCH SPANNZEUGE GMBH

Germany

Collet Holders ER for Double Spindle Machines

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Reducing operating time and downtime Bring together uniform or diverse processing operations to reduce operating times (usually involves multi-spindle heads). The potential applications are virtually limitless: Drilling, threading, counterboring, reaming, milling, etc. The variety of products is equally diverse, from small compact heads with two spindles to multi-spindle XXL units. BENZ offers interchangeable and fixed-flange (stationary) multi-spindle heads in a wide range of configurations. Multi-spindle heads are typically used for mid-size to large-scale series production. We work in close coordination with you, the customer, to find the perfect solution for your application. Using proven standard components as a basis, we create the optimal multi-spindle solution for you. We maintain close contact with leading machine building companies, giving us the necessary expertise to develop the extraordinary. Give us a challenge!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Easy manual actuation The TOROK manual chuck is primarily used in tool prototyping on machines without a clamping cylinder. For example, thanks to its easy manual actuation, when used on grinding machines you can safely and delicately clamp. In combination with our clamping device adaptations, such as the MANDO Adapt mandrel-in-chuck or the jaw module, many more clamping options are possible. Lightweight variant And most recent: Thanks to the optional lightweight CFRP design, with the TOROK CFK you save one-third the weight. This is particularly set-up friendly and it offloads the machine spindle bearings.

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

Cost-effectively process and machine wood, composites and aluminium: We provide series production angle heads for drilling, milling, sawing and grinding in addition to other units for special applications. Benz units are available in a variety of performance classes, making them ideal for everything from light machining to high-performance continuous operation. We have the solution for your special applications: Customized Benz units for machining centers. Put us to the test!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Easy manual actuation The TOROK manual chuck is primarily used in tool prototyping on machines without a clamping cylinder. For example, thanks to its easy manual actuation, when used on grinding machines you can safely and delicately clamp. In combination with our clamping device adaptations, such as the MANDO Adapt mandrel-in-chuck or the jaw module, many more clamping options are possible. Lightweight variant And most recent: Thanks to the optional lightweight CFRP design, with the TOROK CFK you save one-third the weight. This is particularly set-up friendly and it offloads the machine spindle bearings.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Concentric and eccentric complete machining Concentric and eccentric complete machining in a single clamping set-up? That’s right! With our compact chuck you can turn an eccentric position on the workpiece – in a single set-up without having to re-chuck it! Thus you save time and money. Automatic change-over Change-over from concentric to eccentric takes just a few seconds – it is automatic and convenient due to the setting tool in the turret and the c-axis of the machine spindle. Minimum set-up times and no machine changes whatsoever. And first and foremost: You can use your normal clamping cylinder.

Request for a quoteResults for

Machine spindles - Import exportNumber of results

24 ProductsCompany type