- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas meters

Results for

Gas meters - Import export

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

The test bench is designed for calibration with critically operated nozzles of domestic gas meters or others such as diaphragm gas meters, ultrasonic meters, thermoelectric gas meters. The test bench is specially designed for the calibration of domestic gas meters (bellows gas meters, ultrasonic meters, thermoelectric gas meters). The test bench is modular - 1x6 to 4x6 clamping positions for the gas meters can be combined. Due to the modular design 1 to 12 gas meters can be tested simultaneously. In parallel, up to twelve additional test pieces can be adapted, run in and leak tested. A magazine consisting of three critical nozzles is used as flow transmitter. Optionally, a nozzle drum with nine combinable nozzles can be used. This allows the generation of up to 512 different flow points with highest accuracy.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

The rotary gas meters GM4 and GM16 meet the highest demands for reliable and precise reference measurement of smallest quantities up to 0.01 m³/h. They operate according to the direct displacement principle (RPD - rotary positive displacement), in which two counter-rotating pistons convey a fixed volume from the inlet to the outlet of the gas meter with each full revolution. Due to the specially shaped pistons, absolutely pulsation-free operation can be achieved (patent pending). They achieve an excellent measuring accuracy of 0.5 % MW + 0.005 % EW. Both versions are suitable for operation up to 6 bar overpressure. With continuous, absolutely pulsation-free and highly precise flow measurement, the reference gas meters from Ehrler Prüftechnik are the gold standard in the field of small volume measurement. Features: Reference measurement of small flow rates Continuous and absolutely pulsation-free Overpressure operation Excellent measurement accuracy Robust & compact design

Request for a quote

INOX VERTRIEBS GMBH

Germany

INOX Valve & Injection Nozzle Cleaner can be used for all gasoline engines. It dissolves carbonization on valves, inlet area and in the combustion chamber and removes deposits in the entire gasoline injection system. At the same time, the cleaner ensures powerful, clean combustion and optimizes exhaust gas values and injection metering. This results in a longer service life, optimal engine protection and smoother engine running. Applicable for all gasoline engines guarantees optimal injection metering and fuel atomization improves starting behavior and engine performance dissolves carbon deposits on valves, inlet area and in the combustion chamber removes deposits from the entire fuel injection system powerful and clean combustion, optimizes the exhaust gas values guarantees optimal injection metering and fuel atomization longer service life, optimal engine protection, easier and smoother engine running

Request for a quote

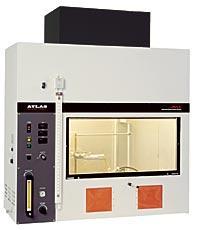

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HVUL2 Horizontal Vertical Flame Chamber is designed for the flammability testing of plastic materials used in consumer electric devices and appliances. The chamber is constructed of stainless steel with a black interior and large sliding window for easy viewing. The HVUL2 includes a fully adjustable specimen support and a precision metered gas burner. Three digital timers with remote control are mounted on the inside back wall of the chamber, allowing for precise and simplified operation. Burner angle adjustable to 0º, 20º, 45º Flexible iris hand access ports Remote burner positioning Sliding tempered glass viewing window Removable burner carriage assembly Flexible laboratory fixturing Interior light Digital timers located in line of sight with specimen Digital timers with resolution of 0.1 sec Remote control with push button reset for in-chamber event timing. Electrical gas shut-off solenoid Gas control system Flame confirmation kit (ASTM D5207) Black interior finish Performs all UL 94 tests (Except Section 10.0 Radiant Panel Test) Bench top chamber (Volume greater than 0.75 m 3) Tirril Burner Multi-directional specimen and burner positioning apparatus Quick release mount for burner during manual operation Large sliding, tempered-glass window for test viewing Exhaust blower (1/3 hp) with variable speed control (580 cfm in free air) Sliding damper for draft free chamber Manometer/pressure gauge, 300 mm Four flame height and sample gauges Interior Dimensions: 122 cm (48'') W x 112 cm (44'') H x 60 cm (23.5'') D Exterior Dimensions: 122 cm (48'') W x 140 cm (55'') H x 61 cm (24'') D Bench Weight: 163 kg (360 lbs) Simple burner angle adjustment (0°, 20°, 45°) Specimen holders for all five Bunsen burner tests Digital timers for specimen test duration, 0.1 sec. resolution Remote control with push button reset for in-chamber event timing Quick release mount for burner during manual operation Hand access openings with irises for closed window access

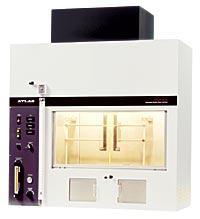

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HVFAA Horizontal Vertical Flame Chamber provides the most accurate means for determining the flammability of aircraft cabin and cargo compartment materials, liners and waste stowage compartment materials, and electric wire. The large volume chamber prevents oxygen depletion during tests. Three digital timers with remote control make specimen event timing precise and convenient. To ensure accurate and repeatable tests, an optional burner flame temperature verification kit is available. The HVFAA is the optimal instrument for conducting repeatable FAA flammability tests. Designed to be used for testing in accordance with FAA's Aircraft Material Fire Test Handbook DOT/ FAA/AR-00/12, Chapters 1.0 - 4.0 (FAR 25.853, 25.855, 25.1359) Draft-free large volume (>0.5m 3) flame chamber Vertical, Horizontal, 45 Degree and 60 Degree Wire Test Packages Sliding hand ports for chamber access Regulated gas control system Calibrated gas flow meter with precision needle valve adjustment ASTM D5025 Bunsen burner with remote positioning Stopwatch plus three handset operated digital timers Tempered glass sliding window Interior inspection light Flame height gauge High temperature exhaust blower with variable speed control ASTM D5207 flame confirmation kit

KROHNE MESSTECHNIK GMBH

Germany

The DK37 M8 is a variable area (VA) flowmeter with electrical signal output and bargraph indication or mechanical indicator with two optional limit switches. The versatile all-metal measuring device is suitable for flow measurement of gases and liquids. Due to its sturdy design, the VA meter can be used at temperatures up to +200°C / +392°F or pressures up to 220 barg / 3190 psig. It is fitted with a needle valve as standard to accurately set the flow value. The DK37 M8 comes with vertical or horizontal process connections for NPT or G thread, flange adapters and many other connection options. To provide constant flow rates in case of variable inlet or outlet pressures, the VA meter is also available with flow regulators. It has approvals for hazardous areas and is suitable for use in Safety Instrumented Systems (SIS).

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The OPTIMASS 2000 is a Coriolis mass flow sensor. Combined with the MFC 400 signal converter it forms the OPTIMASS 2400 high-performance Coriolis mass flowmeter for bulk mass and high volume flow measurement of gases and (non-)conductive liquids.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The DK32/34 is a variable area (VA) flowmeter for measuring low flow rates of liquids and gases. The tried and tested meter is particularly suitable for flow monitoring and dosing in gas analyser systems or on purge panels. Due to its robust all-metal design it can also be used in difficult process conditions with temperatures up to +200°C / +392°F or pressures up to 400 barg / 5800 psig. It is available with a metering valve as standard to accurately set the flow value. The DK32/34 operates without auxiliary power supply. The device just features a local indication with two optional MIN/MAX limit switches (NAMUR) or a reed contact. To provide constant flow rates in case of variable inlet or outlet pressures, the VA meter is also available with flow regulators. It comes with horizontal or vertical process connections for NPT or G thread and many other connection options. The VA meter has various approvals for hazardous areas.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The OPTIMASS 6000 is a Coriolis mass flow sensor. Combined with the MFC 400 signal converter it forms the OPTIMASS 6400 high performance Coriolis mass flowmeter for all process applications including cryogenic or high temperature media as well as high pressure fluids.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Ultrasonic gas flowmeter The OPTISONIC 7300 offers an ultrasonic measurement system dedicated for process gas flow applications. The OPTISONIC 7300 does not have the limitations that are usually associated with traditional gas flow meters like periodical recalibrations, maintenance, pressure loss and a limited flow range. The OPTISONIC 7300 combines the advantages of ultrasonic measurement in a way that it is efficient, reliable and easy to use.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The ALTOSONIC V12 is a 12-chord ultrasonic custody transfer (CT) flowmeter for natural gas. It has been designed to offer the best possible measurement accuracy, not only during calibration under ideal conditions but also during less ideal conditions in the field. As a result, ALTOSONIC V12 is the first ultrasonic flowmeter that was certified to OIML R137 class 0.5 by NMi. Due to its design with 12 acoustic chords a flow conditioner is no longer required; standards such as AGA9, ISO 17089 and MID are met with just 5D straight inlet piping. CBM flowmeter diagnostics are standard and give an exact picture of what is happening inside the flowmeter. With the optional KROHNE Care diagnostic expert system an integrated web server becomes available that presents the results as an easy to access webpage – in plain language.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Flowmeters especially for gases The VA 45 variable area flowmeters were designed to measure gases. They can be used, for example, in industrial ovens, forges and furnaces, and protective gas and heating systems. The standardized device design is available with various connections that conform to standards. The glass measuring cone, protected by a metal sleeve with a viewing glass, makes it easy to read the flow directly.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The all-in-one solution Already the basic version of the OPTISWIRL 4200 is equipped with a temperature compensation for saturated steam applications. With the optional pressure sensor the OPTISWIRL 4200 has an integrated density compensation available, which even allows an exact measurement of gases and superheated steam with varying process conditions. The additional integrated gross and net heat measurement makes the OPTISWIRL 4200 to be a reliable partner for advanced energy management systems. The OPTISWIRL 4200 was designed for the safety-related applications from the very beginning. It was developed according to the standard IEC 61508 edition 2. The certification is effected within the scope of a Full Assessment by TÜV Süd. Thereby the OPTISWIRL 4200 can be used for continuous volume flow measurement in safety-related applications with classification SIL2.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Total-Meter™ is a fully calibrated electronic flow meter with a built-in flow totalizing function. The Total-Meter™ utilizes field-proven differential pressure flow measurement technology to accurately monitor industrial liquids or gases. The actual flow rate is displayed locally on the 4 digit LED display and is also retransmitted with a scalable 4-20mA output for remote monitoring. In addition, the Total-Meter™ tracks total volumetric consumption up to 999,999,999,999 engineering units and will communicate using the ModbusRTU protocol over RS-485/232. The Total-Meter™ is designed to be piped directly into a gas or liquid pipeline and requires minimal space. Integrated programmable flow alarm output can be configured to trigger either high or low flow alarm situations based on actual flow rates.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Gas Mixing Panels include the Waukee brand rotary vane compressors, air and gas Flo-Meters, and either a mechanical carburetor or RatioProver for precise ratio control. Panels are available with additive trim gas or air Flo-Meters. FEATURES: • Available with Lubed Vanes (includes a set of Phenolic Vanes and an Auto Lubricating System) or Non-Lubed Vanes (includes a set of Long Life Composite Vanes) • Available with outlet pressures ranging from 0.5-5.0psig. For higher pressures, consult UPC. • Two options available for ratio control: Standard Carburetor, RatioProver • Available with output capacities ranging from 200-12,000CFH • Available with Built-in Unloader for pressures between 0.5-2.5psig or with Bypass Relief Regulator for pressure lower than 0.5psig or higher than 2.5psig • Available with Standard turndown of 2:1 or 10:1 when used with a Compressor Pressure Controller • Includes Gas and Air Flo-Meters and Air Filter • Available with Trim Gas or Air Flo-Meters

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OPEN GRID EUROPE GMBH

Germany

Open Grid Europe owns and operates mobile gas pressure regulating and metering (GPRM) stations which you can use under a comprehensive, bespoke service contract, for example when you want to maintain the gas flow during work on a pipeline or require a temporary feed-in point to your gas grid. Technical details: Pressures of up to 84 bar Volumetric flow rates of 800 to 100,000 m3/h Can be connected to telemetry systems Adjustable pressures, flows and blending ratios Gas quality conversion from H-gas to L-gas, if required Thanks to the modular design of the system we can build a mobile station tailored to your specific needs complete with all necessary modules such as filters, pre-heaters, instrumentation and control equipment.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

WITT offers high-quality gas mixers / gas blenders and gas metering systems for two or more gases, for high flow rates and highly fluctuating gas withdrawals. You can choose between various options: According to your requirements, WITT gas mixers / gas blenders are available for nearly all technical gases and flow rates: for the optimal gas mixture for welding applications, the required gas concentration for food packages (modified atmosphere packaging = MAP) or the production of synthetic air for medical applications. State-of the art mechanical or electronic gas mixing systems provide accuracy and process safety. You can also control your gas mixing systems conveniently via Intranet, Internet or mobile devices. Combinations of WITT gas mixers / gas blenders with other WITT quality products such as gas analysers are also possible. They can be manufactured as complete system solutions.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

The use of protective gases is an essential element of precise quality control (HACCP) in food packages (Modified Atmosphere Packaging = MAP). MAP gas mixers by WITT provide controlled gas quality and safety in your packaging process – for germfree and preserving food. WITT offers gas mixing and metering systems for all packaging machines used in the food industry, no matter if vacuum packaging, thermo forming, flow pack or chamber packaging machine. The gas mixing systems are adjusted to your specific product type and processing and require only basic installation requirements. WITT system solutions are developed in close collaboration with national food and research institutes. WITT is approved and certified according to ISO 22000 for food safety.

Request for a quote

BLAZE DISPLAY TECHNOLOGY CO.,LTD.

Germany

So far, Blaze Display supplied around 10 billion high quality and reliability LCD displays with long life time (around 15 years), super wide operating temperature(from -40℃ to +90℃), and anti UV function for metering industry. Our Metering LCD Displays (LCD Panels, LCD Modules) are widly used for Kwh Meter, Smart meter, Single phase meter, 3-phase meter, Prepayment energy meter, Electric energy meter, Multi-function energy meter, Water meter, Gas meter, Power meter.

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

for small pipe size DN8~DN50 micro mass flow designed to measure the mass and standard flow in small pipe lines in general industry and laboratory

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

VFM60MV multivariable vortex flowmeters is an integral solution for mass flow /standard flow measurement of steam and gas. Integrated pressure and temperature sensors for density compensation, so it can also measure temperature, pressure, density, mass flow and standard flow. User would only need one flowmeter to measure and read all this parameters, this advantage leads to lower cost and maintaining.

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

TGF600 Screw-in thermal mass flowmeters for small pipe size gas meausred Inline type can be installed/removed without stopping the line Minimum flow rate down to 0.3m/s, 1:100 super wide turndown ratio No moving part, almost no pressure loss Direct mass flow measurement, do not require temperature or pressure compensation TGF600 Series screw-in inline thermal mass flowmeters measures the gas mass flow base on thermal dispersion theory. It combines COMATE’s advanced technology on transmitter, sensor, filming and calibration, can provide stable and accurate measurement even under harsh industrial applications and require very less maintaining.

Request for a quote

HEIFEI COMATE INTELLIGENT SENSOR CO., LTD

Germany

COMATE Inline thermal gas flowmeters with more rugged design to adapt to harsh industrial applications. It implements COMATE’s latest sensor filming technology and high sensitivity sensors to ensure a stable measurement at very low flow rate down to 0.3Nm/s. The standard insertion model can fit in pipe line from DN80~DN500, extended model can fit in smaller pipe down to DN25 and larger pipe up to DN 6000.

Request for a quote

FISCHER ANALYSEN INSTRUMENTE GMBH

Germany

Control valve and Flow indicator for use with calibration gas cylinder. Flow meter markings are nominally 0.5 & 1.0 litres/min.

Request for a quoteResults for

Gas meters - Import exportNumber of results

28 ProductsCountries

Category

- Flowmeters (6)

- Flow meters (4)

- Calibration equipment (1)

- Chemicals - Basic Products & Derivatives (1)

- Diesel engines (1)

- Electronic components (1)

- Extractors, gas and smoke - equipment (1)

- Food Processing (1)

- Gas - production and distribution (1)

- Gas mixtures (1)

- Pipe and tube fittings - ferrous metal (1)

- Ultrasonic measuring equipment (1)