- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas meters

Results for

Gas meters - Import export

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

The test bench is designed for calibration with critically operated nozzles of domestic gas meters or others such as diaphragm gas meters, ultrasonic meters, thermoelectric gas meters. The test bench is specially designed for the calibration of domestic gas meters (bellows gas meters, ultrasonic meters, thermoelectric gas meters). The test bench is modular - 1x6 to 4x6 clamping positions for the gas meters can be combined. Due to the modular design 1 to 12 gas meters can be tested simultaneously. In parallel, up to twelve additional test pieces can be adapted, run in and leak tested. A magazine consisting of three critical nozzles is used as flow transmitter. Optionally, a nozzle drum with nine combinable nozzles can be used. This allows the generation of up to 512 different flow points with highest accuracy.

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

The rotary gas meters GM4 and GM16 meet the highest demands for reliable and precise reference measurement of smallest quantities up to 0.01 m³/h. They operate according to the direct displacement principle (RPD - rotary positive displacement), in which two counter-rotating pistons convey a fixed volume from the inlet to the outlet of the gas meter with each full revolution. Due to the specially shaped pistons, absolutely pulsation-free operation can be achieved (patent pending). They achieve an excellent measuring accuracy of 0.5 % MW + 0.005 % EW. Both versions are suitable for operation up to 6 bar overpressure. With continuous, absolutely pulsation-free and highly precise flow measurement, the reference gas meters from Ehrler Prüftechnik are the gold standard in the field of small volume measurement. Features: Reference measurement of small flow rates Continuous and absolutely pulsation-free Overpressure operation Excellent measurement accuracy Robust & compact design

Request for a quote

THORNE & DERRICK

United Kingdom

Thorne & Derrick International, based in the UK, are leading Specialist Distributors of Metering products for commercial, industrial and hazardous area applications – we supply meters for water, gas and heat (thermal energy) metering from leading manufacturers in a range of technologies including Ultrasonic, Clamp-on, Diaphragm, Rotary, Turbine, Electromagnetic (Magmeter) and Woltmann. We provide excellent customer service from our trained sales engineers specialising in recommending the optimum meter to ensure the highest accuracy and reliability of measurement – we can recommend meters to ensure compliance with approval and regulatory schemes including RHI, MID and WRAS and also specify metering products to achieve BREEAM credits for sustainable buildings.

Request for a quote

DS GAS CONNECTION LTD

United Kingdom

We provide a gas connection for all residential users no matter if they are new users or returning users. We have a capacity to connect your home in short time. All our installations are made according to UK safety standards.

NINGBO TOWER INDUSTRY CO.,LTD

China

Propane Tank Gauge Level Leak Detector for QCC1 Propane Tank, Brass Propane Tank Adapter Pressure Meter Gauge

Request for a quote

BOAGAZ MANAGEMENT GMBH

Austria

Flange fitting DN 20 1 M-0040526 Flange fitting DN 25 1 M-0040527 Flange fitting DN 32 1 M-0040528 Gas meter fitting DN 20 x R 1 3/8" 1 M-0040529 Gas meter fitting DN 25 x R 1 3/8" 1 M-0040530 Gas meter fitting DN 32 x R 1 3/8" 1 M-0040531

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Promix gas dosing stations for physical foaming have been specially designed and developed to meet the needs of foam extrusion. Promix gas metering technology is characterized by high dosing accuracy, reliability and amazingly simple operation. Promix gas dosing stations meet all the requirements of a modern gas metering system for foam extrusion. These include high-precision mass flow control, process visualization by means of trend charts, operator-definable operating limits, data acquisition, and synchronization of the dosing rate with the extruder output. Implementation in the extruder control system via fieldbus system is also possible. •,Mass flow from 1 g/h up to 20'000 g/h •,Dosing pressure up to 680 bar

Request for a quote

INOX VERTRIEBS GMBH

Germany

INOX Valve & Injection Nozzle Cleaner can be used for all gasoline engines. It dissolves carbonization on valves, inlet area and in the combustion chamber and removes deposits in the entire gasoline injection system. At the same time, the cleaner ensures powerful, clean combustion and optimizes exhaust gas values and injection metering. This results in a longer service life, optimal engine protection and smoother engine running. Applicable for all gasoline engines guarantees optimal injection metering and fuel atomization improves starting behavior and engine performance dissolves carbon deposits on valves, inlet area and in the combustion chamber removes deposits from the entire fuel injection system powerful and clean combustion, optimizes the exhaust gas values guarantees optimal injection metering and fuel atomization longer service life, optimal engine protection, easier and smoother engine running

Request for a quote

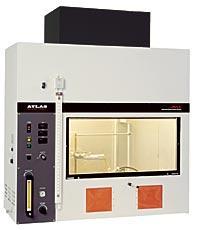

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HVUL2 Horizontal Vertical Flame Chamber is designed for the flammability testing of plastic materials used in consumer electric devices and appliances. The chamber is constructed of stainless steel with a black interior and large sliding window for easy viewing. The HVUL2 includes a fully adjustable specimen support and a precision metered gas burner. Three digital timers with remote control are mounted on the inside back wall of the chamber, allowing for precise and simplified operation. Burner angle adjustable to 0º, 20º, 45º Flexible iris hand access ports Remote burner positioning Sliding tempered glass viewing window Removable burner carriage assembly Flexible laboratory fixturing Interior light Digital timers located in line of sight with specimen Digital timers with resolution of 0.1 sec Remote control with push button reset for in-chamber event timing. Electrical gas shut-off solenoid Gas control system Flame confirmation kit (ASTM D5207) Black interior finish Performs all UL 94 tests (Except Section 10.0 Radiant Panel Test) Bench top chamber (Volume greater than 0.75 m 3) Tirril Burner Multi-directional specimen and burner positioning apparatus Quick release mount for burner during manual operation Large sliding, tempered-glass window for test viewing Exhaust blower (1/3 hp) with variable speed control (580 cfm in free air) Sliding damper for draft free chamber Manometer/pressure gauge, 300 mm Four flame height and sample gauges Interior Dimensions: 122 cm (48'') W x 112 cm (44'') H x 60 cm (23.5'') D Exterior Dimensions: 122 cm (48'') W x 140 cm (55'') H x 61 cm (24'') D Bench Weight: 163 kg (360 lbs) Simple burner angle adjustment (0°, 20°, 45°) Specimen holders for all five Bunsen burner tests Digital timers for specimen test duration, 0.1 sec. resolution Remote control with push button reset for in-chamber event timing Quick release mount for burner during manual operation Hand access openings with irises for closed window access

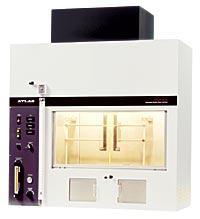

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HVFAA Horizontal Vertical Flame Chamber provides the most accurate means for determining the flammability of aircraft cabin and cargo compartment materials, liners and waste stowage compartment materials, and electric wire. The large volume chamber prevents oxygen depletion during tests. Three digital timers with remote control make specimen event timing precise and convenient. To ensure accurate and repeatable tests, an optional burner flame temperature verification kit is available. The HVFAA is the optimal instrument for conducting repeatable FAA flammability tests. Designed to be used for testing in accordance with FAA's Aircraft Material Fire Test Handbook DOT/ FAA/AR-00/12, Chapters 1.0 - 4.0 (FAR 25.853, 25.855, 25.1359) Draft-free large volume (>0.5m 3) flame chamber Vertical, Horizontal, 45 Degree and 60 Degree Wire Test Packages Sliding hand ports for chamber access Regulated gas control system Calibrated gas flow meter with precision needle valve adjustment ASTM D5025 Bunsen burner with remote positioning Stopwatch plus three handset operated digital timers Tempered glass sliding window Interior inspection light Flame height gauge High temperature exhaust blower with variable speed control ASTM D5207 flame confirmation kit

CLIXAR

Ukraine

Magnet M2 is an antimagnetic security sticker seal made as a sticker with a transparent capsule. The sticker seal has a special adhesive composition that makes it possible to attach the seal to plastic, metal, glass, and painted surfaces. The capsule contains a special suspension, which irreversibly changes its pattern when exposed to a magnetic field. Changes in this pattern are evidence that intruders were making an attempt to influence the meter with a magnet to modify its readings. An additional level of protection of the tamper-evident seal Magnet M2 is provided by a special inscription "OPENED", which appears when someone attempts to remove the seal from the surface and does not disappear even if an effort is made to glue the seal back on. This makes it easy for inspection authorities to spot an attempted seal tampering.

Request for a quote

CLIXAR

Ukraine

Magnet is an antimagnetic security sticker seal made as a sticker with a transparent capsule. The sticker seal has a special adhesive composition that makes it possible to attach the seal to plastic, metal, glass, and painted surfaces. The capsule contains a special suspension, which irreversibly changes its pattern when exposed to a magnetic field. Changes in this pattern are evidence that intruders were making an attempt to influence the meter with a magnet to modify its readings. An additional level of protection of the tamper-evident seal Magnet is provided by a special inscription "OPENED", which appears when someone attempts to remove the seal from the surface and does not disappear even if an effort is made to glue the seal back on. This makes it easy for inspection authorities to spot an attempted seal tampering.

Request for a quote

CLIXAR

Ukraine

The Magnet UV tamper-evident seal is an antimagnetic sticker seal. It is designed to control the protection of metering devices. It consists of a sticker base with a protective layer, a transparent plastic capsule, and a magneto-sensitive suspension inside the capsule. The sticker base has a special inscription - "OPENED" - that appears when there is an attempt to remove the seal from the surface. The inscription does not disappear if the sticker is attached back on. The capsule features a UV glow effect, which makes it easy to check the integrity of the seal in poor lighting conditions. The magneto-sensitive suspension irreversibly changes its pattern when an attempt is made to influence the meter with a magnet with the intention to alter the readings. Clixar manufactures two types of Magnet UV seals that have different sensitivity thresholds - 50 mT and 100 mT. The transparent capsule makes it possible to protect

Request for a quote

CLIXAR

Ukraine

PGS is a locking device for pipes made of polycarbonate or polypropylene. It is designed to seal cap nuts to prevent their twisting and disconnection of pipes, as well as the removal of gas meters and installation of bridge cables for bypass devices for the purpose of stealing gas. The pipe locking device consists of two semicircular-shaped parts with additional holes for the sealing rope. To install the pipe locking device, it is necessary to connect both parts on the mounting nut, put the sealing rope into the special holes on the sides of PGS, and install the seal (rotary or latch one). The seal should be placed as close as possible to the locking device. The tamper-evident seal and rope will prevent intruders from keeping the fact of removal of the seal and the locking device from the nut unnoticed. When an attempt is made to perform certain actions with the aim to steal gas or water, visible signs appear on the seal, which is evidence

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Ultrasonic gas flowmeter The OPTISONIC 7300 offers an ultrasonic measurement system dedicated for process gas flow applications. The OPTISONIC 7300 does not have the limitations that are usually associated with traditional gas flow meters like periodical recalibrations, maintenance, pressure loss and a limited flow range. The OPTISONIC 7300 combines the advantages of ultrasonic measurement in a way that it is efficient, reliable and easy to use.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KROHNE MESSTECHNIK GMBH

Germany

Sensor for bulk mass flow Whilst the OPTIMASS 2000 has been developed to meet the demanding custody transfer requirements of the Oil & Gas industry, it is well suited to bulk measurement in many applications. The option of Super Duplex (UNS S32750) provides a maximum operating pressure of 180 barg / 2610 psig. The newly launched OPTIMASS 2000 S400 meter with the innovative four straight tube design is with a max. flowrate of 4 600 t/h / 169 000 lb/min the highest capacity Coriolis mass flowmeter in the world. OPTIMASS 2400 with EGM™ (Entrained Gas Management): the meter maintains operation over a wide range of gas fractions and complex flow conditions.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Small flowmeters (metal) The DK 37 variable area flowmeters can either be equipped with a mechanical or electronic indicator and are suitable for measuring gases and liquids. They are sturdy, versatile all-metal measuring devices. All devices are fitted with a metering valve to accurately set the flow value. PPS housing as standard, stainless steel housing as option.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The OPTIMASS 6000 is a Coriolis mass flow sensor. Combined with the MFC 400 signal converter it forms the OPTIMASS 6400 high performance Coriolis mass flowmeter for all process applications including cryogenic or high temperature media as well as high pressure fluids.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Flowmeters especially for gases The VA 45 variable area flowmeters were designed to measure gases. They can be used, for example, in industrial ovens, forges and furnaces, and protective gas and heating systems. The standardized device design is available with various connections that conform to standards. The glass measuring cone, protected by a metal sleeve with a viewing glass, makes it easy to read the flow directly.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Small flowmeters (metal) The DK 32 and DK 34 variable area flowmeters are versatile and can be used for gases and liquids. The sturdy all-metal design ensures high resistance to pressure, temperature and media and stands up to extreme application and environmental conditions. The position of the float is magnetically transmitted to an analog indicator to display the measured value. No power supply is necessary.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The all-in-one solution Already the basic version of the OPTISWIRL 4200 is equipped with a temperature compensation for saturated steam applications. With the optional pressure sensor the OPTISWIRL 4200 has an integrated density compensation available, which even allows an exact measurement of gases and superheated steam with varying process conditions. The additional integrated gross and net heat measurement makes the OPTISWIRL 4200 to be a reliable partner for advanced energy management systems. The OPTISWIRL 4200 was designed for the safety-related applications from the very beginning. It was developed according to the standard IEC 61508 edition 2. The certification is effected within the scope of a Full Assessment by TÜV Süd. Thereby the OPTISWIRL 4200 can be used for continuous volume flow measurement in safety-related applications with classification SIL2.

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

Advanced Nova Swiss technology allows high-precision gas mixing under controlled pressure. The servo motor ensures state-of-the-art pressure regulation that is optimal for the respective application. This results in maximum precision for the injection process and ensures exact gas metering at the required pressure. Benefits : High flow rates Maximum pressure precision Low maintenance costs No daily re-adjustment required Faster start-up after interruptions. Thereby less waste during the start-up process. No compressed air supply required. Contamination-free gases thanks to diaphragm technology. The Nova Swiss gas injection unit does not require compressed air, as it is the case with pneumatic amplifiers. The integrated lubrication unit allows the system to be operated at very low speed, which in turn enables the dimensioning of extremely small quantities.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Total-Meter™ is a fully calibrated electronic flow meter with a built-in flow totalizing function. The Total-Meter™ utilizes field-proven differential pressure flow measurement technology to accurately monitor industrial liquids or gases. The actual flow rate is displayed locally on the 4 digit LED display and is also retransmitted with a scalable 4-20mA output for remote monitoring. In addition, the Total-Meter™ tracks total volumetric consumption up to 999,999,999,999 engineering units and will communicate using the ModbusRTU protocol over RS-485/232. The Total-Meter™ is designed to be piped directly into a gas or liquid pipeline and requires minimal space. Integrated programmable flow alarm output can be configured to trigger either high or low flow alarm situations based on actual flow rates.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Gas Mixing Panels include the Waukee brand rotary vane compressors, air and gas Flo-Meters, and either a mechanical carburetor or RatioProver for precise ratio control. Panels are available with additive trim gas or air Flo-Meters. FEATURES: • Available with Lubed Vanes (includes a set of Phenolic Vanes and an Auto Lubricating System) or Non-Lubed Vanes (includes a set of Long Life Composite Vanes) • Available with outlet pressures ranging from 0.5-5.0psig. For higher pressures, consult UPC. • Two options available for ratio control: Standard Carburetor, RatioProver • Available with output capacities ranging from 200-12,000CFH • Available with Built-in Unloader for pressures between 0.5-2.5psig or with Bypass Relief Regulator for pressure lower than 0.5psig or higher than 2.5psig • Available with Standard turndown of 2:1 or 10:1 when used with a Compressor Pressure Controller • Includes Gas and Air Flo-Meters and Air Filter • Available with Trim Gas or Air Flo-Meters

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for gas flow measurement. These meters are fitted with integrated motorized flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The FurnaceMeter™ meets current NFPA86...

Request for a quote

OPEN GRID EUROPE GMBH

Germany

Open Grid Europe owns and operates mobile gas pressure regulating and metering (GPRM) stations which you can use under a comprehensive, bespoke service contract, for example when you want to maintain the gas flow during work on a pipeline or require a temporary feed-in point to your gas grid. Technical details: Pressures of up to 84 bar Volumetric flow rates of 800 to 100,000 m3/h Can be connected to telemetry systems Adjustable pressures, flows and blending ratios Gas quality conversion from H-gas to L-gas, if required Thanks to the modular design of the system we can build a mobile station tailored to your specific needs complete with all necessary modules such as filters, pre-heaters, instrumentation and control equipment.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

WITT offers high-quality gas mixers / gas blenders and gas metering systems for two or more gases, for high flow rates and highly fluctuating gas withdrawals. You can choose between various options: According to your requirements, WITT gas mixers / gas blenders are available for nearly all technical gases and flow rates: for the optimal gas mixture for welding applications, the required gas concentration for food packages (modified atmosphere packaging = MAP) or the production of synthetic air for medical applications. State-of the art mechanical or electronic gas mixing systems provide accuracy and process safety. You can also control your gas mixing systems conveniently via Intranet, Internet or mobile devices. Combinations of WITT gas mixers / gas blenders with other WITT quality products such as gas analysers are also possible. They can be manufactured as complete system solutions.

Request for a quoteResults for

Gas meters - Import exportNumber of results

50 ProductsCountries

Company type

Category

- Flow meters (6)

- Flowmeters (6)

- Magnetic equipment (4)

- Cabinets and cupboards (1)

- Calibration equipment (1)

- Chemicals - Basic Products & Derivatives (1)

- Diesel engines (1)

- Electronic components (1)

- Extractors, gas and smoke - equipment (1)

- Food Processing (1)

- Gas - production and distribution (1)

- Gas detectors (1)

- Gas extraction - systems and equipment (1)

- Gas mixtures (1)

- Heating - greenhouses (1)

- Injection pumps and systems (1)

- Laboratory equipment and instruments (1)

- Pipe and tube fittings - ferrous metal (1)

- Plumbing installations (1)

- Pneumatic system components (1)