- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bulk material

Results for

Bulk material - Import export

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

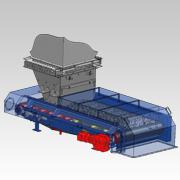

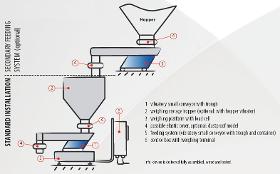

Whether for large or small conveyed quantities, no matter the application, from luxury food processing to the steel industry, AViTEQ Belt weigh feeders assure high weighing precision for reliable, uninterrupted operations. In automated production processes requiring constant weighing and metering, Weiteq Belt Weigh Feeders are the first choice. Advantages and benefits For feeding a wide range of bulk materials from free flowing to bridging High long- and short-term accuracy Robust construction allows ease of installation and belt replacement Customized feeder sizes, belt type and feed hopper based on bulk material handling experience Special solutions for high-accuracy feeding and heavy duty operating condition Can be used with different types of feeding equipment and directly at the silo outlet Application Components feeding for blending Feeding of additives Batch charging Wagon and truck loadingFeeding and control systems for mills, crushers and mixers Technical data WBL-L WBF-M W

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Vibrating table can be used both for compression and also for loosening bulk material. Typical applications are compacting of e.g. concrete mixes or the unstick/knock out of molds. There are two different approaches: The load to be vibrated, is set loosly on the table or firmly clamped to the vibrating device. Advantages & benefits variable, can be used for different tasks easy to regulate with magnetic vibrator Construction Compact design, with attached magnetic vibrator/s or unbalanced motors below the tabletop. Selection The sizing depends on: bulk material, such as bulk density, particle shape and internal friction the properties of the container, such as height, stiffness and sidewall Key figures length: up to 4,000 mm width: up to 2,000 mm payloads: up to 3,000 kg drive: magnetic vibrator, unbalanced motor, exciter

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-trough conveyor are suitable for conveying and metering of pourable bulk material up to almost any particle size. By ensuring robust and open, trough-shaped structure are particularly suitable conveyors in extreme environmental conditions, because of the easy cleaning ability, but also happy in the chemical and food industry. Advantages & benefits Wide range of applications: using magnetic vibrator drive(s) or vibrator(s) dust-proof versions available long conveying inserted through serial connection possible multiple drive possible execution in mild steel or stainless steel Construction Conveyors are characterized by their simple design. The main components are: conveyor with drive traverse drive in-/outlet pipe (covered variants) elastic support elements flexible seals Selection The sizing is dependent on: bulk material throughput required geometry possible installation mass Key figures length: up to 9,000 mm on single units, theoretically unlimited for conveyor lines

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

The AViTEQ Hopper discharge unit is used below hoppers, silos, bunkers or bulk containers for flowable bulk materials and serves as a combined closure, discharge, transportation and metering device. It is used where high material flows are required. Short hopper discharge units are mounted directly below the bulk hopper. Depending on the bulk material, the discharge unit can be fitted with appropriate protective linear and sealing systems. Advantages & benefits robust design and therefore long-lasting variable feeding speed with magnetic vibrator for optimal dosing to the process bunker closure without additional barriers arrangment central below the bunker run, simple and professional installation possible upon request, in a dust-tight design to save the environment Construction The main components are: conveyor bunker shoe for product guiding inside the feeder drive elastic support elements optional: flexible sealings optional: needle or blade gate for closing Selection The s

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

A ViTEQ Loss-in-Weight Feeders are designed to ensure a continuous, gravimetric and high tolerance batch dosing of flowable bulk materials that are not hygroscopic, adhesive or interleaving features. The feeders are sSuitable for many bulk materials including those with the following characteristics: fragile (food products) abrasive (coarse powder, pellets, granulate) difficult to handle (like fibres, glass fibres, pharmaceutical powders) Suitable for wherever precise dosing and weighing of the main components and additives is necessary. Ideal in the following industries: Food & Animal Feed Plastics / Chemicals Pharmaceuticals Advantages & benefits less shear and pressure forces Troughs have a dead space-free design quick and easy cleaning, maintenance-free vibration discharge very gentle weighing (volumetric and gravimetric) highly precise dosing high throughputs Construction Technical data WLW-L WLW-M WLW-H Trough length (mm) 275 - 1.100 275 - 1.100 275 - 1.100 Trough wi

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Contaminated bulk material is cleaned One of the most annoying and expensive problems with bulk material processing is the contamination by foreign substances. These contaminants not only reduce the quality of the final product, they also cause damage to the machines and failures. Especially high-strength small metal parts such as screws, nuts, washers, or cotter pins cause serious damage to the processing machinery. For this reason, the production costs with contract processing are often uncontrollable. Ebbecke has the production under control To solve this costly nuisance, the engineers of Ebbecke Verfahrenstechnik AG have developed their own system with which goods that have been contaminated by metal particles can be cleaned. This is done using the inductively-working metal detector that detects even the finest metal abrasions and reliably separates them from the goods. Through a trouble-free production process delays, non-compliance of supply contracts and consequent compensatio

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Testing plants in the area of bulk material processing Innovations made by Ebbecke Verfahrenstechnik To create a product exactly according to the ideas of the customer, standardized procedures are sometimes not enough. That’s why customers come from all over Europe to Ebbecke Verfahrenstechnik AG in Central Hesse – because our engineers are prepared to develop entirely new process engineering methods. With the new and further development of procedures and machines we are at the same time opening up alternative business areas for our customers. Testing and development without financial risk With all technical developments, our engineers keep the efficiency of the processes in sight. Because one thing is clear: An innovation can only prevail on the market if the development and subsequent purchase price remain within defined economic boundaries. This is where Ebbecke Verfahrenstechnik AG has been impressing for years with its pilot plants as centers of in-house development work. Toget

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Dry micronization The optimal solution for fine grinding of bulk material We offer you a wide range of different types of plants for contract grinding in our fine grinding centers. Among them are special grinding plants, such as a special mill for natural products, an efficient circulating gas plant and a cryogenic grinding system for temperature-sensitive products. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. Grain size exactly as you request it! Our fine grinding plants enable the dissolution of agglomerates as well as the breaking up of solid grain structures up to the finest grinding in a reproducible product quality. Customers of Ebbecke Verfahrenstechnik AG appreciate the flexibility of the available grinding systems that can be customized to suit the specific requirements of the grinding process. Nothing is left to chance because cutti

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Screening The right screening procedure for any size and virtually any bulk material Ebbecke Verfahrenstechnik AG has the right plants and a know-how developed over decades for the best screening results with virtually any bulk material. For this reason, customers come to us for contract screening from the cosmetics, pharmaceutical, food, chemical and animal feed industries. Cutting-edge technology As a contract screening company active for many years we know what the priorities are for our customers. For these needs, we have self-developed our contract screening plants from Planoscreen and Planodry types. With these advanced contract screening plants not only can we screen contaminate-free , we can at the same time dry the screened product under a nitrogen atmosphere or a pressure cascade. In addition to the machines and process engineering plants that we have developed we also screen on systems from other manufacturers. For this completely different screening procedures are used d

Request for a quoteResults for

Bulk material - Import exportNumber of results

10 ProductsCountries

Company type

Category