- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bulk material

Results for

Bulk material - Import export

IPF ELECTRONIC GMBH

Germany

Ultrasonic sensors are non-contact and wear-free position switches which can also be used under rough environmental conditions. A key advantage of these devices lies in the fact that the material and the surface characteristics of the objects to be detected can be almost anything. Solids, liquids, grainy materials and powdery materials can be identified without the shape or the color of the object having any influence to the measured result. In addition, the ability to detect transparent materials such as films and fluids is of particular importance. The shape and color of the objects do not influence the result of the detection. The capability to detect transparent films or liquids is also of special importance. Ultrasonic sensors are used for distance measurement (e.g. detection of diameters, loop control), for fill level detection (e.g. silo detection), for positioning and presence detection (e.g. glass pane positioning, film tear check, glass bottle detection)

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Lutz-Jesco dry material feeders are precise and reliable devices for volumetric conveying of pourable substances. These devices consist of self-supporting welded constructions made of high-quality stainless steel sheet, which ensures their robustness and durability. Available in various conveying capacities, the dry material feeders offer flexible adaptation to different requirements and areas of application. They are equipped with hollow screws (screw spindles), which ensure even and continuous material transport. Thanks to this technology, they can feed a wide range of bulk materials, including fine dust particles, pellets, flakes and short fibres. Lutz-Jesco dry material feeders are ideal for industrial applications where precise dosing is required, such as in the chemical industry, food processing and many other sectors.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

FOR VARIOUS INDUSTRIES AND A VARIETY OF APPLICATIONS LIPP bulk silos are being used from a variety of industries and companies for different applications. Since decades, LIPP silos are used for the storage of grain in flower mills or as storage for animal feed in the agricultural sector. Also the furniture and wood industry is using LIPP silos to store wood chips or saw dust. ADVANTAGES OF LIPP BULK STORAGE A growing application is the storage of pallets for biomass plants. Different manufacturing companies are using LIPP bulk material silos as storage of buffer for their raw materials. The enhanced stability coming from the Double Fold System allows to construction of silos with big diameter and height ratio, with free carrying roofs as well as a fast filling and extraction. The silos can be built in closed manufacturing halls or building, very narrow installation sites and on high steel or concrete structures.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 74/2 double installation provides improved operational reliability, since the pumps alternate to pump waste water (which has already been separated from bulk materials) from the separator. Bulk materials are first pumped into the pressure line, then the line is flushed with pre-cleaned water from the tank. Multi-family homes Where the reserve pump has to guarantee fail-safe operation e.g. in restaurants and public buildings Facilities that cannot be drained using natural gradient As protection from backwater damage Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One tank with separator system Two centrifugal pumps and motors according to type and operating location required Two non-return valves AWASTOP DN 100 K Two pressure pipe gate valves DN 100 Level measurement LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

GUARANTEED OPTIMUM STORAGE FOR A WIDE VARIETY OF MATERIALS The storage of bulk materials needs to be not only cost effective but also safe, and systems should be easy to integrate in production processes. LIPP Double Seam technology and welded LIPP tanks have proven to be particularly suitable for bulk storage applications in industry and agriculture. LIPP silos provide a high level of stability and total leak tightness and protect bulk materials from moisture. The smooth internal walls of the silos are a benefit that pays dividends when storing special media. All kinds of bulk materials Grain Soya Silage fodder Woodchips Pellets Clinker brick Cement SILOS FOR STORING GRAIN AND OTHER FOODSTUFFS Grain, soya and other foodstuffs are precious commodities and a major asset in agriculture and they need to be stored particularly carefully. With the tried and tested Lipp Double Seam System, Lipp silos offer major benefits in terms of design and leak tightness.

Request for a quote

HO-MA GMBH

Germany

Our ascending conveyors (metering elevators) are designed for different volumes. Products are fed as bulk material to downstream machines.Metering elevator and feeding system for bulk materials

Request for a quote

HO-MA GMBH

Germany

Our ascending conveyors (dosing elevators) are designed for different volumes. Products are fed as bulk material to downstream machines.Dosing elevator and feeding system for bulk material

Request for a quote

BÜRKLE GMBH

Germany

The core sampler can be used to take samples of bulk materials which can easily become stuck or settle during sampling due to their particle form. In comparison to standard all-layer samplers for bulk materials, the two-part core sampler has no gap dimensions in which the medium can become stuck while it is being removed. This makes it possible to take a proper sample of powders and granulates through multiple layers, for example glass balls or metal powders. Depending on the size, the stainless steel sampler can be used for a wide range of different containers, for example big bags or small containers. The bulk material sampler takes a representative core sample and is ideal for use in various laboratory and industrial applications.

Request for a quote

HO-MA GMBH

Germany

Our ascending conveyors (dosing elevators) are designed for different volumes. Products are fed as bulk material to downstream machines. Dosing elevator and feeding system for bulk material

Request for a quote

HO-MA GMBH

Germany

Our ascending conveyors (dosing elevators) are designed for different volumes. Products are fed as bulk material to downstream machines. Dosing elevator and feeding system for bulk material

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

The screw elements can be mounted on a square shaft. You transport bulk materials into bins or silos via rotary movements.

Request for a quote

MESUTRONIC GMBH

Germany

SPECIAL CONVEYING SYSTEMS TRANSTRON SERIES S / M / L / XL / CM / CL / CX CONVEYING OF PACKED PRODUCTS AND BULK MATERIALS IN THE PRODUCTION LINE WITH “METAL FREE AREA” FOR THE INTEGRATION OF METAL DETECTOR. High value tailored solutions. Reliable continuous operation. Guaranteed long-term, trouble-free metal detection results.

Request for a quote

MESUTRONIC GMBH

Germany

Metal separator for the examination of free falling bulk materials, fulfilling even most stringent hygiene requirements. Detects all metals encapsulated or as loose parts Extremely precise metal detection – impressively reliable Immune against outside interference Easy to clean – fulfils the highest hygienic demands Compact, easily integrated

Request for a quote

GURTEC GMBH

Germany

With over 12million units sold globally, the GUP Series is our most popular roller offering the best value for money in light and medium bulk materials handling. We’ve been manufacturing GUP rollers since 1980, using a fully automated production line that guarantees GURTEC’s German engineering quality in every roller, with the shortest lead times in the market.

Request for a quote

BÜRKLE GMBH

Germany

The bucket is made entirely of high-gloss polished stainless steel. The smooth surface of the stainless steel bucket makes it easy to clean. The rounded, movable handle makes it comfortable to move the bucket. The laboratory bucket is suitable for moving liquids and bulk materials properly, especially in the chemical, pharmaceutical or cosmetic industries, and in the food and animal feed industries.

Request for a quote

MESUTRONIC GMBH

Germany

METAL SEPARATOR FOR SUCTION AND PRESSURE LINES, COMPLYING TO STRICTEST HYGIENE REQUIREMENTS Detects and separates all metals encapsulated or as loose parts. Extremely precise metal detection – impressively reliable. Immune against outside interference. The suitable unit for all bulk materials (granulates/powders).

Request for a quote

MESUTRONIC GMBH

Germany

METAL SEPARATOR FOR EXAMINATION OF BULK MATERIALS IN FREE FALL. Detects and separates all metals encapsulated or as loose parts. Extremely precise metal detection – impressively reliable. Durable and solid – a profitable investment. ATEX conforming versions available. Compact, easily integrated.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

A ViTEQ Loss-in-Weight Feeders are designed to ensure a continuous, gravimetric and high tolerance batch dosing of flowable bulk materials that are not hygroscopic, adhesive or interleaving features. The feeders are sSuitable for many bulk materials including those with the following characteristics: fragile (food products) abrasive (coarse powder, pellets, granulate) difficult to handle (like fibres, glass fibres, pharmaceutical powders) Suitable for wherever precise dosing and weighing of the main components and additives is necessary. Ideal in the following industries: Food & Animal Feed Plastics / Chemicals Pharmaceuticals Advantages & benefits less shear and pressure forces Troughs have a dead space-free design quick and easy cleaning, maintenance-free vibration discharge very gentle weighing (volumetric and gravimetric) highly precise dosing high throughputs Construction Technical data WLW-L WLW-M WLW-H Trough length (mm) 275 - 1.100 275 - 1.100 275 - 1.100 Trough wi

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

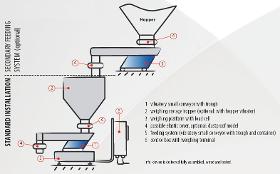

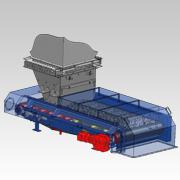

Whether for large or small conveyed quantities, no matter the application, from luxury food processing to the steel industry, AViTEQ Belt weigh feeders assure high weighing precision for reliable, uninterrupted operations. In automated production processes requiring constant weighing and metering, Weiteq Belt Weigh Feeders are the first choice. Advantages and benefits For feeding a wide range of bulk materials from free flowing to bridging High long- and short-term accuracy Robust construction allows ease of installation and belt replacement Customized feeder sizes, belt type and feed hopper based on bulk material handling experience Special solutions for high-accuracy feeding and heavy duty operating condition Can be used with different types of feeding equipment and directly at the silo outlet Application Components feeding for blending Feeding of additives Batch charging Wagon and truck loadingFeeding and control systems for mills, crushers and mixers Technical data WBL-L WBF-M W

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Vibrating table can be used both for compression and also for loosening bulk material. Typical applications are compacting of e.g. concrete mixes or the unstick/knock out of molds. There are two different approaches: The load to be vibrated, is set loosly on the table or firmly clamped to the vibrating device. Advantages & benefits variable, can be used for different tasks easy to regulate with magnetic vibrator Construction Compact design, with attached magnetic vibrator/s or unbalanced motors below the tabletop. Selection The sizing depends on: bulk material, such as bulk density, particle shape and internal friction the properties of the container, such as height, stiffness and sidewall Key figures length: up to 4,000 mm width: up to 2,000 mm payloads: up to 3,000 kg drive: magnetic vibrator, unbalanced motor, exciter

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-trough conveyor are suitable for conveying and metering of pourable bulk material up to almost any particle size. By ensuring robust and open, trough-shaped structure are particularly suitable conveyors in extreme environmental conditions, because of the easy cleaning ability, but also happy in the chemical and food industry. Advantages & benefits Wide range of applications: using magnetic vibrator drive(s) or vibrator(s) dust-proof versions available long conveying inserted through serial connection possible multiple drive possible execution in mild steel or stainless steel Construction Conveyors are characterized by their simple design. The main components are: conveyor with drive traverse drive in-/outlet pipe (covered variants) elastic support elements flexible seals Selection The sizing is dependent on: bulk material throughput required geometry possible installation mass Key figures length: up to 9,000 mm on single units, theoretically unlimited for conveyor lines

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

The AViTEQ Hopper discharge unit is used below hoppers, silos, bunkers or bulk containers for flowable bulk materials and serves as a combined closure, discharge, transportation and metering device. It is used where high material flows are required. Short hopper discharge units are mounted directly below the bulk hopper. Depending on the bulk material, the discharge unit can be fitted with appropriate protective linear and sealing systems. Advantages & benefits robust design and therefore long-lasting variable feeding speed with magnetic vibrator for optimal dosing to the process bunker closure without additional barriers arrangment central below the bunker run, simple and professional installation possible upon request, in a dust-tight design to save the environment Construction The main components are: conveyor bunker shoe for product guiding inside the feeder drive elastic support elements optional: flexible sealings optional: needle or blade gate for closing Selection The s

Request for a quote

BÜRKLE GMBH

Germany

Novartos Uno sampler with two or three sample chambers, for one sample zone. Novartos the Pharma zone sampler for sampling according to FDA guidelines for Unit-Dose-Sampling. It is now possible to withdraw a double- or triple-sample without inserting the lance repeatedly into the bulk material. Mixing is mainly prevented in this way. One significant advantage of Novartos is the easy cleaning. Complete filling and emptying of sample chambers has been improved substantially using computer-optimised geometry. There are no crevices or dead spaces where sampling residues can collect.

Request for a quote

MINEBEA INTEC GMBH

Germany

Dymond Bulk guarantees precise X-ray inspection of bulk materials in the food industry. Foreign bodies such as stones or metal are consistently detected and removed from the material flow to protect both products and machines. Maximum detection sensitivity for product and machine safety Intuitive operation Worldwide service, including remote support High-performance interfaces for straightforward integration into networks

Request for a quote

BÜRKLE GMBH

Germany

It is possible to take multiple samples from bulk goods with this sampler quickly and easily. Emptying has been greatly simplified and in this model takes place via the tip. The advantage: The sample can be emptied directly into the sample container without having to disassemble the EasySampler, in order to obtain a mixed sample for instance. The bulk material must be free-flowing or self-flowing.

Request for a quote

HARRER UND KASSEN GMBH

Germany

Microwave Resonator, Continuous In Line Moisture measurement Description The microwave resonance measurement uses the electromagnetic energy stored inside a resonator to determine the water content of a product. Via a non conducting window, the resonator field is coupled into the material located in front of the resonator. This so called leakage field is not radiated. Depending on the dielectric properties of the product, the shift of resonance frequency and bandwidth of the resonator is used for measurement. The ratio of bandwidth and frequency shift is density independent. The measurement is highly suitable for bulk material.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Anywhere small quantities of wastewater need to overcome a high discharge head is the perfect application for the flattened version of the AWALIFT 2/2, with a shape that makes it a good space-saving option. It also offers our proven bulk materials collection system and is installed dry. The system controls are individually adjusted and installed in a switch cabinet outside of the shaft. Draining small towns with up to about 1700 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, underground stations etc. Product features One holding tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Four pump gate valves Two STRATE non-return valves Two pressure pipe gate valves DN 100 One Y-pipe DN 100

Request for a quote

VKF RENZEL GMBH

Germany

The transparent food dispensers help to reduce the amount of outer packaging. Sell loose goods such as rice, noodles, pulses, cereals or baking ingredients for independent dispensing in the individually required quantity. The food dispensers are available in different sizes. They are filled from above via a large lid opening. Due to gravity, the bulk material always falls down where it can be filled into a container by operating a lever. The suspension device on the rear side is designed in such a way that even containers with different capacities end uniformly at the removal height. A conversion to unpackaged articles is child's play with the help of our products!

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

The Keiper UNITRANS conveyor belt series can be fitted with different sidewalls. Sidewalls are used as margin stops, usually together with cleats and entraining elements, in ascending and descending conveyor systems. The sidewalls prevent the products from falling off the sides of the belt. Inclined conveying: steep or angled conveying up to a slope of 80° in connection with cleats. Horizontal conveying: transporting bulk material and different-sized products. Conveyor belt sidewalls made of PVC, PU or special materials such as PU foam, polyolefin or polyester. With or without fabric interlayers. With or without foot. In the colors blue, white, green petrol, black or transparent. Depending on the design, in oil- and grease-resistant quality as well as FDA/EU approval. High abrasion and cutting resistance.

Request for a quoteResults for

Bulk material - Import exportNumber of results

92 ProductsCountries

- Germany (92)

- Bonn, Düsseldorf and North Rhine and Westphalia (18)

- Bremen and region (9)

- Frankfurt am Main and Hesse (21)

- Hamburg and region (1)

- Hannover and Lower Saxony (7)

- Kiel and Schleswig-Holstein (1)

- Leipzig and Saxony (2)

- Munich, Nuremberg and Bavaria (6)

- Stuttgart, Freiburg and Baden-Wurtemberg (22)

- Weimar and Thuringia (5)

Category

- Conveyor systems (5)

- Quality control and certification (5)

- Tanks, metal (3)

- Sensors (2)

- Conveyor belts (2)

- Electromagnets (2)

- Lifting - vehicles (2)

- Water - production and distribution (2)

- Weighing and dosing equipment (2)

- Wheels, castors and rollers - metal (2)

- Bearings - ball, needle and roller (1)

- Goods handling systems, continuous (1)

- Buckets and grabs, crane (1)

- Building materials, manufacture - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Construction machinery (1)

- Dosing - machines and equipment (1)

- Folding, bending and welding of rubber and plastic (1)

- Food Processing (1)

- Grids, gratings and wire mesh (1)