- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- form parts

Results for

Form parts - Import export

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quote

KURO KUNSTSTOFFE GMBH

Germany

We want to produce the optimal product for every application area. Our CNC portal Milling Machine for tubes offers to you a wide range of possibilities. When machining, you rely on us for perfect treatment. The CAM programming defines an optimal milling strategy, so we guarantee a customer-and product-specific machining solution as well as a high flexibility.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

The economic adjustment to small batch sizes, we meet with our turned parts for the direct assembly in plastics and die-cast products. Any thread forms such as, thread-tapping (DIN7500), thread cutting (DIN 7513-7516) or KTG for direct screw in plastics are realized cost-effectively. Advantage is the elimination of high tooling costs, since no counter-thread in the workpiece (eg threaded inserts, nuts, etc.) is required because the direct assembly takes place directly into the workpiece. Only a given tube is required in order to screw it directly. Our turned parts replace previously cold formed parts used (so-called multi-station presses) which require high output volumes in order to achieve a reasonable price parts.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Dolly Docks from Lödige facilitate the airside loading and unloading of air cargo units Dolly docks receive and send off ULDs on airside. Fast and smooth transfer is essential. Our dolly docks can be equipped with a hydraulic tilting function and can form part of an airlock. Sized and equipped to your requirements, the dolly docks from Lödige will facilitate your airside interface.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts made form aluminum, and process into machine housing.After milling by CNC mchine, then doing black anodize.They are mainly used in architectural field.

Request for a quote

BORNEMANN GMBH

Germany

The tool top (stamp) has an internal form, whose bottom part (matrix) has the corresponding opening (see image). These punch units are used in the areas of sheet shaping. Contact I have read and agree to the privacy policy. *Pflichtfelder

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Large Quantities: produced as cold formed parts (so-called multi-station presses), which require high output volumes in order to achieve a reasonable price parts Small Quantities: Produced as turned parts - the economic adjustment to small batch sizes Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry, sheet metal processing industry, telecommunications, tank- and container construction.

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

DIETZ GMBH

Germany

We can produce the parts you require using specific tools or on special-purpose machines. We produce complex forms and assembly parts with strip thicknesses of 0.10 to 3.00 and with strip widths of up to 100 mm – depending on the material used. The manufacturing processes that we offer include: Punching, forming, embedding, welding, bolting, riveting and mounting. We perform the assembly of small batches by hand, while larger volumes are performed automated if you so wish. Our hybrid sub-assembly production includes the over-moulding of punched parts made of wire or metal with a variety of plastics or silicones. In order to ensure that the desired braking element features optimum properties, we make use of both the temperature durability and the haptic advantages of silicone and the weight advantage of plastic when combining these materials in this fashion. Guide tube assemblies, a combination of springs and tubes, are part of the hybrid component portfolio.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Advanz™ 6CM – s118 is a heat treatable product for automotive structural and inner applications. Advanz™ 6CM – s118 was primarily developed for hood inners, in order to meet the highest pedestrian safety requirements while also offering a 6xxx series uni-alloy solution. In the as-supplied temper, this product is soft and highly formable – ideally suited to form complex parts such as hood inners. Developed for inner closure panels with special requirements, Novelis Advanz™ 6CM – s118 has excellent forming characteristics as well as a superior bending performance. Advanz™ 6CM -s118 has moderate strength after paint baking and offers controlled energy absorption in a crash situation. All values are typical.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Less wear, longer working lives In the automobile industry, environmental protection is also playing an ever greater role. With its dimensions, bodies form by far the largest part of recyclates in automobile recycling. One of the major challenges in crushing vehicle bodies is in the vulnerability to wear of many hammer axes. We have optimised our solutions over a number of years and supply hammer axes for large shredders in various diameters, which are characterised by extreme toughness and dimensional stability. This is how our clients profit from optimum working lives for their recycling machines.

Request for a quote

HONSEL-GROUP

Germany

As a specialist for cold forming, HONSEL manufactures customised solid parts with close tolerances in a wide range of geometries. The specialised manufacturing depth and the 100 % quality control of the produced parts are the hallmarks of the company. HONSEL bolts, installed in millions of clutch systems worldwide, are a first-class example of this. Asymmetric bolts — Up to 12 mm shaft diameter — Variable shaft lengths — Asymmetric head geometries possible to meet customers’ wishes

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Aluminium wire We manufacture hard drawn and annealed aluminium wire at our site in Rothenburg/Saale. Materials / DIN EN E-aluminium according to EN 60889 Aluminium-magnesium-silicon alloys according to EN 50183 Aluminium content min. 99.5 % Aluminium for cold forming parts

Request for a quote

VOM HOFE KALTSTAUCHDRAHT GMBH

Germany

Discover the world of stainless steel wire from Vom Hofe Kaltstauchdraht GmbH - your excellent source for wire solutions that combine robustness with timeless elegance. Our stainless steel wire stands for outstanding performance, precision and the many years of expertise of a pioneer in the wire business. Robust elegance for demanding applications: Our stainless steel wire combines robust construction with timeless elegance and is the ideal choice for a wide range of demanding applications. Whether in the manufacture of screws, nuts, rivets, cold-formed parts or in the automotive industry - our stainless steel wire impresses with its versatility.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 1800 is a fully automated foil application and sealing machine, suitable for plastic, tin or glass containers. mobile base frame feed conveyor with feed control synchronised star wheel stand with receptacles for the containers as form parts adjustable outer ring for guiding containers through the machine sequence foil magazine for stackable pre-cut Ballerstaedt seals pneumatically driven foil dispenser with a precise, maintenance free 180° reverse gear for removing the seals from the magazine, applying them to the sealing edge and fixing them with a pre-sealer sealing station for closing the containers with regulation of the sealing temperature, pressure and time for optimal setting of the seal parameters, conductive, optional also inductive exit conveyor for the containers central height adjustment of the magazine plate to adjust it to the respective container height all-over protective coating control panel with electrical supply unit

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For gripping small parts and forming wires • Tips bent 45°, smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles coated with plastic • Made of tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For gripping small parts and forming wires • Smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles coated with plastic • Made of tool steel, forged, oil-hardened

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

VCI corrosion protection skin film for form-fitting packaging of metal parts.

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• Most popular shape for assembly work, trimming printed circuit boards, also for radio and telephone work • For gripping small parts and forming wires • Tips bent 45°, smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles with ergonomically shaped ESD multi-component sleeves, electrically conductive • Made of tool steel, forged, oil-hardened

Request for a quote

MECHASYS GMBH

Germany

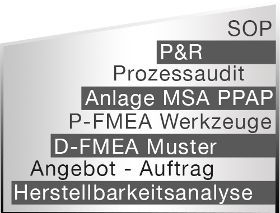

In terms of project management, the respective feasibility study is a matter of course. No offer without a feasibility study. -An offer implies manufacturability; this is how our process is defined! - We live from prototypes and small series. Often there is no second assignment, so there shouldn't be any unforeseen surprises. Or at least only within a manageable framework. The combination of metal and plastic composite parts makes this a challenge from time to time. But you can be sure that here we draw on a wealth of experience that we would like to share with you.

Request for a quote

RUHLAMAT GMBH

Germany

Test systems and inspection systems form an integral part of most of the automated solutions we employ. Each assembly process is usually followed by an inspection process so that the highest quality requirements can be satisfied. Both laboratory as well as stand alone or inline series inspection systems (EOL) have already been widely implemented by ruhlamat. Inspection results (product/process data) are documented in individual or customer-specific databases (traceability). Seamless traceability of product and process data Inline process control and monitoring Efficiency through timely trend control 100% inspection

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers finished or semi-finished parts directly formed from polyimide powder with all the attributes of sintered PI. The advantage of direct formed parts are the lower costs as quantitiy is increasing. Due to almost zero percent waste during production it can be a more economic production method. Machined parts are widely used for small series high precision applications. Polyimide direct formed parts can be used in different applications: Automotive industry: racing engine fuel line. Jet engine: vane bushing or lock nut insert. Industrial machinery: hotrunner systems nozzles or plasma cutting torch as gas distributers or sealing components. Semicon HDPCVD Equipment: e.g. heater coil spacer. Life sciences: rotor seal or pneumatic surgical tool vane.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers polyimide powders for various processes. The Dexnyl PI powder is available in two different particle sizes. Our Dexnyl PI Powder 100P_19 suitable for compounding and compression molding application and our Dexnyl PI Powder 260_19 is suitable for producing compression molded and direct formed parts. The range of products that can be produced from our polyimide (PI) is only limited by the processing machines. Polyimide powder can be processed by hot compression molding, direct forming, iso-static compression molding or it can be compounded with other materials as an additive. Polyimide powder is often compounded with PTFE to increase certain properties of the PTFE.

Request for a quote

PERO AG

Germany

At the PERO laboratory for technical cleanliness that forms part of our Centre of Competence, we analyse and assess the outcomes of the cleaning tests. Analytical lab, vacuum drying unit, testing instruments Examination under light microscope Assessment of cleanliness analyses according to VDA 19 and other standards

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The APG-process by HÜBERS permits short cycle times thanks to rapid gelation and demoulding with automatic opening and closing of the mould. During the gelling process, fresh material is supplied continuously to the mould under pressure in order to prevent cracks and voids and to compensate for the shrinkage of the material. The mould is held together by the clamping machine. The degassed material is injected into the APG mould directly from the static mixer. Shrinkage compensation is carried out by the HÜBERS metering pumps. One central mixing and metering system can serve several clamping machines. In this case each clamping machine has its own static mixer positioned directly in front of the mould and also has its own shrinkage compensation unit to maintain the pressure. The system is supplied via a ring line which requires no maintenance and is free of sedimentation. In principle the length of this line is insignificant.

Request for a quote

SIMPAC EUROPE GMBH

Germany

Hydraulic presses are suitable for the high-precision forming of various parts, whereby the maximum press capacity is available in every position of the slide. In combination with their flexibility in terms of slide speed and dwell time, they are also particularly suitable for press hardening applications. Overview: ● Press capacity: 1,500 - 25,000 kN ● Part size: small, medium, large ● Application: for the production of drawn parts or as part of a press hardening line Description and benefits: ● Slide movement either pressure and / or travel-dependent ● Specially designed hydraulic system without shift shock during operation ● Motorized oil circulation with cooling or heating unit The models for press hardening are available in 8,000, 12,000 or 16,000 kN and come with a newly developed combination of servomotor and hydraulics that allows higher speeds in the closing and return movement of the slide.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The core-layer mat former (pocket orienter) deals with the material ow from the metering bin infeed, the bin discharge front up to the orienter underneath. We use the FinFormer, which orients the strands crosswise to production direction. Distribution rollers form parts of the FinFormer, orienting the core-layer strands homogeneously in longitudinal and crosswise directions onto the forming belt underneath. The FinFormer is suitable for all strand geometries. Depending on the requirements one or two mat formers are used. Features Position-controlled, swivelling twin screw conveyor Bin metering belt, incl. weight-per-unit-area control Discharge front rollers, extremely wear-resistant FinFormer including distributing rollers and pocket orienter rollers underneath Level and angle adjustment of the orienter head Advantages Most homogeneous density distribution inside the bin crosswise to production direction Careful strand treatment

Request for a quote

TAMPOPRINT GMBH

Germany

TAMPOPRINT GmbH is a well-established partner for the European brand manufacturers in the toy industry. Our pad printing and laser marking automatic machines meet the highest quality requirements when used in multi-shift operation with high throughput speed. Highest precision of the print image registration on convex, round or flat parts using the pad printing process, one to multicolor, in colorful micro printing are a matter of course and meet the high standards of modern industrial products. Process monitoring using camera systems will secure the quality of your production. Whether smallest toy parts, difficult shape formings or large-sized toy parts, smallest eyes or colorful areas, TAMPOPRINT has the suitable automation.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

VENTAPP radial fans are used in wood-processing plants where air or loaded air is conveyed under increased pressure. They convey gases, bres, and particles; they are used for wetting, drying or ltering of media. In energy plants, in bre drying, for mat formers and dust extraction systems they form integral parts of Siempelkamp plants. Features Pressures beyond 20,000 Pa Temperatures up to 700 °C Impeller wheel diameters up to 3,150 mm Circumferential speed up to 200 m/s Gas-tight and pressure-resistant design ATEX Advantages High eciency Smooth operation Robust design Low caking, high wear resistance High dependability and operational safety Diverse accessories Maintenance and repair service Variants Drive type Casing positioning Size of all components Angular position Material Colour

Request for a quoteResults for

Form parts - Import exportNumber of results

41 ProductsCountries

Company type

Category

- Building hand tools, non-power (4)

- Mechanical transmission - components (3)

- Measurement - Equipment & Instruments (2)

- SMALL METAL PARTS (2)

- Screws (2)

- Wood veneer - machinery and equipment (2)

- Nuts (1)

- Steels and metals - forming and cutting (1)

- Additives for plastics industry (1)

- Anti-corrosion products, chemical (1)

- Bearings - ball, needle and roller (1)

- Cars - electrical and electronic parts and components (1)

- Cleaning machines, industrial (1)

- Components and parts for small household appliances (1)

- Electric and electronic components - machines for manufacturing (1)

- Forges - machinery and installations (1)

- Hoses, pipes and tubes - plastic (1)

- Industrial cutting machine tools (1)

- Management training (1)

- Metal industrial presses (1)