- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- form parts

Results for

Form parts - Import export

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 1800 is a fully automated foil application and sealing machine, suitable for plastic, tin or glass containers. mobile base frame feed conveyor with feed control synchronised star wheel stand with receptacles for the containers as form parts adjustable outer ring for guiding containers through the machine sequence foil magazine for stackable pre-cut Ballerstaedt seals pneumatically driven foil dispenser with a precise, maintenance free 180° reverse gear for removing the seals from the magazine, applying them to the sealing edge and fixing them with a pre-sealer sealing station for closing the containers with regulation of the sealing temperature, pressure and time for optimal setting of the seal parameters, conductive, optional also inductive exit conveyor for the containers central height adjustment of the magazine plate to adjust it to the respective container height all-over protective coating control panel with electrical supply unit

Request for a quote

MECHASYS GMBH

Germany

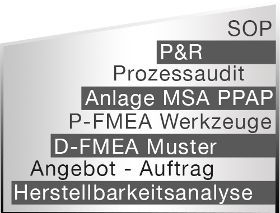

In terms of project management, the respective feasibility study is a matter of course. No offer without a feasibility study. -An offer implies manufacturability; this is how our process is defined! - We live from prototypes and small series. Often there is no second assignment, so there shouldn't be any unforeseen surprises. Or at least only within a manageable framework. The combination of metal and plastic composite parts makes this a challenge from time to time. But you can be sure that here we draw on a wealth of experience that we would like to share with you.

Request for a quote

SIMPAC EUROPE GMBH

Germany

Hydraulic presses are suitable for the high-precision forming of various parts, whereby the maximum press capacity is available in every position of the slide. In combination with their flexibility in terms of slide speed and dwell time, they are also particularly suitable for press hardening applications. Overview: ● Press capacity: 1,500 - 25,000 kN ● Part size: small, medium, large ● Application: for the production of drawn parts or as part of a press hardening line Description and benefits: ● Slide movement either pressure and / or travel-dependent ● Specially designed hydraulic system without shift shock during operation ● Motorized oil circulation with cooling or heating unit The models for press hardening are available in 8,000, 12,000 or 16,000 kN and come with a newly developed combination of servomotor and hydraulics that allows higher speeds in the closing and return movement of the slide.

Request for a quote

TAMPOPRINT GMBH

Germany

TAMPOPRINT GmbH is a well-established partner for the European brand manufacturers in the toy industry. Our pad printing and laser marking automatic machines meet the highest quality requirements when used in multi-shift operation with high throughput speed. Highest precision of the print image registration on convex, round or flat parts using the pad printing process, one to multicolor, in colorful micro printing are a matter of course and meet the high standards of modern industrial products. Process monitoring using camera systems will secure the quality of your production. Whether smallest toy parts, difficult shape formings or large-sized toy parts, smallest eyes or colorful areas, TAMPOPRINT has the suitable automation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

The trend – particularly in the automotive industry – is towards lightweight materials. Aluminium and magnesium alloys are in increasing use in many fields of technology. So fastening technology needs to adapt too. Aluminium offers countless options because the material is so versatile for cold forming. Under the Alufast® name ARNOLD UMFORMTECHNIK has brought together screw fasteners and form parts made from aluminium. Our many years of experience working with aluminium, including extensive research are your guarantee of optimum fastening results. We are constantly optimising our processes, ensuring that our Alufast® products are always at the latest state of technology.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

We use the latest high-gloss polished and coated forming tools for the cold-forming proess. This means we achieve very high accuracy. Some examples of Conform® precision parts: drive shafts for small to medium-sized electric motors, e.g. for windshield wipers window winder seat adjuster bearing bushes locking pins ABS functional parts ESP functional parts

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Manufacture by machining is battling against the rising cost of materials and long machining times. That's why many companies are finding our forming process for hollow parts of increasing interest. We have other forming options for machine-finishing in-house. Our cold-forming process is distinctive – including for thin-walled hollow parts because of: rolled (chip-free manufacture) external threads suitable surfaces for maximum corrosion requirements Some examples of Conform® hollow parts and nuts: sensor housing union nuts for hydraulic, brake and fuel lines clinch nuts

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

With Conform® components our customers can reduce their procurement and assembly costs: We handle the preceding processes thus enabling slimmer procedures at our customers’ own production facilities. So that we can meet the wide variety of component needs for our customers, we work within a network of certified partners. Some examples of components made to customer specifications: cold-formed parts in steel cold-formed parts in aluminium rubber decoupling elements plastic injection-mouldings stampings metal bending parts non-detachable washers or sealing rings

Request for a quoteResults for

Form parts - Import exportNumber of results

10 ProductsCompany type