- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- component seals

Results for

Component seals - Import export

W. KÖPP GMBH & CO. KG

Germany

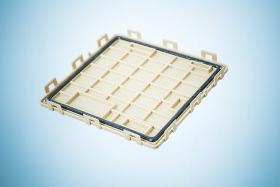

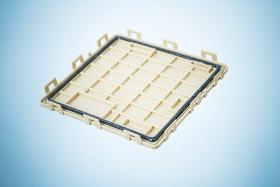

We seal your housings, control cabinets or lighting units, apply adhesives or cast electronic components. In addition to the proven, high-performance 2-component PUR seals (FIPFG), we cover other important areas of application for our customers by applying homogeneous 1-component seals. For example, if your application requires higher temperature and/or chemical resistance or may be less compressible than a foamed seal. Our one-component, elastic solutions are also used for electrically conductive seals. We dose silicones, polyurethanes or MS polymers in liquid, unreacted form directly onto your component. True to contour on the smallest geometries, extremely adhesive and durable. Perfect sealing – sealing, gluing, casting directly on the component. Absolutely true to the contour and directly onto your component. We enable our customers to do this in series thanks to state-of-the-art dosing systems.

Request for a quote

ROLLON GMBH

Germany

Compact Rail is a linear system consisting of steel linear rails with induction hardened raceways and high precision radial ball bearing sliders, also made of hardened steel. Thanks to their self-aligning capabilities, Compact Rail linear guides simplify the project, improve the performance and reduce the overall cost of application. Compact Rail linear guides are easy to install on all types of surfaces, including non-machined ones. Compact Rail linear guides feature a robust steel slider with ball bearings, self-centering heads with wipers, longitudinal seals to protect the internal components and a top sealing strip. The slider body is accurately finished with matte longitudinal edge chamfer and a shining ground flat surface. The slider heads are equipped with special slow release felt pads and are free to rotate with respect to the slider body, so that the felts are always in contact with the raceways to ensure optimal lubrication.

Request for a quote

WERNER LANGER GMBH & CO. KG

Germany

For companies from the construction supply industry, we manufacture among others insulating mat holders and plastic dowels in a variety of lenghts. In the sanitary sector, our portfolio/range varies from drainage components through radiator holders in individual parts as well as complete modules to plastic parts for shower cubicles. We also produce components for sealing systems for windows and doors.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

We seal your housings, control cabinets or lighting units, apply adhesives or cast electronic components. In addition to the proven, high-performance 2-component PUR seals (FIPFG), we cover other important areas of application for our customers by applying homogeneous 1-component seals. For example, if your application requires higher temperature and/or chemical resistance or may be less compressible than a foamed seal. Our one-component, elastic solutions are also used for electrically conductive seals. We dose silicones, polyurethanes or MS polymers in liquid, unreacted form directly onto your component. True to contour on the smallest geometries, extremely adhesive and durable. Perfect sealing – sealing, gluing, casting directly on the component. Absolutely true to the contour and directly onto your component. We enable our customers to do this in series thanks to state-of-the-art dosing systems.

Request for a quote

BILLI DICHTUNGSTECHNIK GMBH

Germany

Mechanical seals for the food industry are used in a very broad range of industry sectors, such as in breweries, wine and cider productions, beverage industry, cheese dairies, creameries, juice productions, producers of "soft drinks", etc. In this case, the various components of the seal are made of FDA approved materials. Our mechanical seals are suitable for use in: KSB ®, A.P.V. ®, Alfa Laval ®, FRISTAM ® Lowara ®, TUCHENHAGEN ®, HILGE ®, INOXPA PROLAC ®, INDAG ®, GRUNDFOS ®, JABSCO ®, JOHNSON ®, etc.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Metallic materials of the seal components of GMN labyrinth metal seals - series L/M - guarantee highest resistance against coarse and fine contamination.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

In the FIPFG process, a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. Highly elastic, dimensionally accurate and cost-effective seals that are perfectly connected to the workpiece: KOPP has been offering this to you for more than 15 years in the form of FIPFG sealing systems. In the FIPFG process (formed-in-place-foam-gasket), a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. The possibilities of the technology are as diverse as our customers' requirements for the seals themselves. This makes on-site technical advice essential. Thanks to our experience and technical expertise, we always find the perfect solution with our customers. Through our own toolmaking and construction and application consulting, we can produce quickly, flexibly and cost-effectively.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

In the FIPFG process, a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. Highly elastic, dimensionally accurate and cost-effective seals that are perfectly connected to the workpiece: KOPP has been offering this to you for more than 15 years in the form of FIPFG sealing systems. In the FIPFG process (formed-in-place-foam-gasket), a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. The possibilities of the technology are as diverse as our customers' requirements for the seals themselves. This makes on-site technical advice essential. Thanks to our experience and technical expertise, we always find the perfect solution with our customers. Through our own toolmaking and construction and application consulting, we can produce quickly, flexibly and cost-effectively.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Sealing sets for oil motors Material: NBR Category Hydraulic systems, valves and components / Hydraulic motors / Accessories / Sealing kit Product number supplier 46050019

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Sealing sets for oil motors Material: NBR Category Hydraulic systems, valves and components / Hydraulic motors / Accessories / Sealing kit Product number supplier 46050019

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste MF. Silver-grey high-temperature paste with solid lubricants Description Castrol Molub-Alloy Paste MF (previous product name Castrol Optimol Paste MF) is particularly suitable for assembling screw connections in the high temperature range up to +1100 °C . Even under extreme pressures, it protects the surfaces from scoring, corrosion and seizing. In high-temperature areas, in wet conditions and in aggressive environmental influences, Castrol Molub-Alloy Paste MF seals the components and ensures good separation. Application Castrol Molub-Alloy Paste MF can be used for components at risk of corrosion, exposed to high temperatures and the environment , such as hot-screw connections, spark plug and lambda sensor threads.

Request for a quote

MERECS ENGINEERING GMBH

Germany

We are experienced in test system development for leakage testing, life time testing and end-of-line test stands in the field of gas & hydrogen technology. We also have a network of suppliers and partners who provide key components for leakage measurement, piping, sealing and instrumentation. As a general contractor and integrator, Merecs Engineering can individually design, assemble and commission the test system at our customers' sites.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

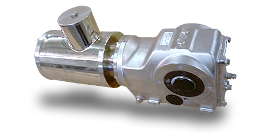

KAISER-MOTOREN GMBH

Germany

Stainless steel motors are used in sanitary areas such as in the food and beverage industry or in the pharmaceutical sector. The smooth surface of the motors is designed in accordance to the EHEDG guidelines to avoid dirt accumulation. To ensure longlasting and lowmaintenance operation, critical components such as bearings and seals are specially tested. Due to an extensive stock of motor components, standard and special motors can be delivered in a short time. Here are some of the common specifications Sizes 63160 0.18 to 22 kW 2 8 pole windings Special windings Enclosure IP66, optional IP69K Special shaft ends Terminal box or cables

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – Large container / handling stations (tubs) are semi-automatic system components for separating, filling, sealing and capping tubs and canisters and can be used individually or in combination. This enables the precise and modular realisation of your specific tasks on the basis of tried and tested stations. Container separating stations Filling positions with filling valve(s) or manual filling stations Sealing stations with head space gassing or evacuation Capping and screwing systems We would be delighted to integrate these or other handling stations in your production process. A common, unified transport system is only one reason for the reliability of each station and the interaction with the upstream and downstream processes. Buffer sections and synchronisation devices are standard here, and can also be combined with our stockpiling systems.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Until now, the perfume and flavouring industry had hardly any satisfactory solutions for the exact mixing of powdery substances, which often led to weighing errors, blocked valves and production downtimes. The FRICKE PD1 powder dosing system was specially developed to meet these challenges. With a 6 kg scale (1 mg resolution), it automates the dosing of 20 powder components, which are stored in sealed stainless steel containers (10 litres). Various dosing elements and stirrers enable lump-free and dust-free processing. The advantages include high accuracy, reproducibility and simple software integration into the batch management system.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

In interaction with the sonotrode, the anvil produces and shapes the joint and thus is one of the core components of the ultrasonic sealing process. Sealing of films requires focusing of the energy by means of the tooling profile, which is mostly mounted to the anvil. Highest rigidity and plane parallelism ensure best joint quality. Anvil profiles are essential for the quality of the weld result and are produced to customer requirements and adapted to respective applications.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers finished or semi-finished parts directly formed from polyimide powder with all the attributes of sintered PI. The advantage of direct formed parts are the lower costs as quantitiy is increasing. Due to almost zero percent waste during production it can be a more economic production method. Machined parts are widely used for small series high precision applications. Polyimide direct formed parts can be used in different applications: Automotive industry: racing engine fuel line. Jet engine: vane bushing or lock nut insert. Industrial machinery: hotrunner systems nozzles or plasma cutting torch as gas distributers or sealing components. Semicon HDPCVD Equipment: e.g. heater coil spacer. Life sciences: rotor seal or pneumatic surgical tool vane.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

2 Component Fiber Sealing System impregnated with Graphite and MoS2 lubricant Pressure Capability is dependent on design of endrings. Characteristics Simple installation Use without barrier fluid Maintenance free Shaft protecting No adjusting of gland Re-pressurize in operation Operating range Velocity [v max]: 12 m/s Temperature: t = -40… +315 °C pH: 2 - 12 Density: 1.10 g/cm³ Pressure Capability is dependent on design of endrings. Main application Equipment which is badly accessible Worn shaft sleeves Non centric running shafts Suitable for Higher Temperature applications Accessories Special endrings made of HPU and PTFE/Graphite compound for non centric running shafts Form of delivery Unit for H- and P-Type: Cans 1 kg, hobbock of 25 Kg 2 Component System Component H: Is used for the basic manual fill of the stuffing box. Component P: Is used for Injection with press DVS TP 9000.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

2 Component Fiber sealing system impregnated with PTFE and special lubricant Pressure Capability is dependent on design of endrings. Characteristics Simple installation Use without barrier fluid Maintenance free Shaft protecting No adjusting of gland Re-pressurize in operation Operating range Velocity [v max]: 8 m/s Temperature: t = -10… +180 °C pH: 2 - 12 Density: 1.10 g/cm³ Pressure Capability is dependent on design of endrings. Main application Equipment which is badly accessible Worn shaft sleeves Non centric running shafts Pulper Suitable for Universal use Accessories HPU Endrings Form of delivery Unit for H- and P-Type: Cans 1 kg, hobbock of 25 Kg 2 Component System Component H: Is used for the basic manual fill of the stuffing box. Component P: Is used for Injection with press DVS TP 9000.

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

HT/S Advantage™ / PolarExtreme Reman Fan Drives & HT Now there's a superior alternative to upgrading an HT/S Advantage or S Fan Drive that endures the harshest environments: PolarExtreme Repair Kits. PolarExtreme Repair Kits feature seal components constructed from hydrogenated buna nitrile rubber (HBNR) to enhance the Horton fan drive for extreme conditions. The PolarExtreme super Kit includes the new PFD (Piston Friction Disc) with a unique fin design for better heat dissipation. These kits mean PolarExtreme delivers the ultimate upgrade with: - Longer life - Better abrasion resistance - 30% greater tolerance to temperature extremes - Less likely to suffer spiral fatigue - Less breakage and leakage Horton blue seals identify these kits as the extreme performer — PolarExtreme. PolarExtreme Seal Kit Repairs and upgrades Horton HT/S Advantage and S Air-Engaged Fan Drives Blue D- & O-ring, cartridge assembly, face seal assembly, System Sentry®, umbrella check valve, spline lubricant, spline lubricant brush, socket head screws. PolarExtreme Super Kit Repairs and upgrades Horton HT/S Advantage Air-Engaged Fan Drives PolarExtreme PFD (Piston Friction Disc) with a unique fin design for better heat dissipation, hub assembly, sheave bearings, friction facing, lock nut, blue PolarExtreme D- & O-ring, cartridge assembly, face seal assembly, System Sentry, umbrella check valve, spline lubricant, spline lubricant brush, socket head screws. Related Products - HT/S Advantage Air-Engaged Fan Drives - Advantage Reman Fan Drives & Genuine Horton Repair Kits Links - Order or View Literature - On-line Catalog

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

require high precision, large rated moving load, and high maximum rotation speed. By adopting the new technology of material processing, KFB has successfully manufactured bearings of long service life that are highly fatigue resistant and impact resistant. The types of bearings made by KFB for the metallurgical roller mills are: split bearings; unit rollers; support roller bearings; single row, double row, three row, four row cylindrical roller bearings, fully-loaded cylindrical roller bearings, spherical roller bearings. The use of split bearings appreciably facilitates assembly and repair operations compared to the use of nonsplit (conventional) bearings. It does away with the need for the disassembly and subsequent reassembly of intermediate parts and mechanisms, which is required when replacing conventional bearings. It also reduces costs and production losses. If provided with efficient cooling, reliable lubrication and proper sealing, split-bearing components can be used...

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM Automation, your partner in - IV catheters - dialyzers - drip chambers - lab-on-a-chip systems, used for various diagnostic analyses and processes in the laboratory on a single chip Assembly and inspection plants in medical engineering that we have been involved in: - Fiber and panel membrane filters - Syringe and infusion systems - Tablet storage and packaging - Flacons / Flacon caps - Lipstick and mascara containers - Coronary testers / rapid blood tests - Sterile caps / membrane seal systems - Components for inhalers - Surgical disposable razors Testing and inspection lines for: - Pacemakers - Dialysis filters Hygienic design is also important here. Back in 2008, we established a clean room in line with Class C / ISO Class 7 requirements in our manufacturing facilities specially for this application area.

Request for a quote

HEBMÜLLER GMBH

Germany

Traditionally, our rubber-to-metal seals are used in the engine and transmission sectors, often with the elastomer FKM / FPM.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-quality NiroSan® SF press fittings with red moulded sealing rings made of FKM and NiroSan® stainless steel system pipes according to EN 10312. Specially made for all applications that require silicone free components. Silicone-free moulded sealing rings are ideally suited to applications such as varnishing and painting industries. All NiroSan® SF press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. Certified in accordance with all relevant national and European certification bodies.

Request for a quoteResults for

Component seals - Import exportNumber of results

35 ProductsCountries

Category

- Lubricants, industrial (6)

- Foams, rubber (4)

- Seals (4)

- Precision measuring instruments (2)

- Bottling and filling - machinery and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Electric motors - dC (1)

- Filtering equipment and supplies (1)

- Gas detectors (1)

- Hydraulic equipment (1)

- Insulating seals (1)

- Internal transport systems (1)

- Mechanical engineering - custom work (1)

- Pipe and tube fittings - ferrous metal (1)

- Plastic products for the electronics industry (1)

- Sealing rings (1)

- Varnishing - steels and metals (1)