- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- component seals

Results for

Component seals - Import export

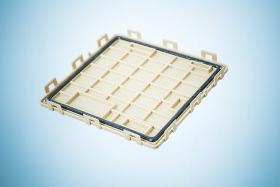

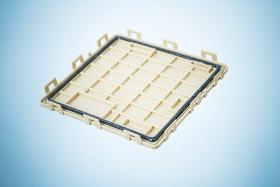

W. KÖPP GMBH & CO. KG

Germany

We seal your housings, control cabinets or lighting units, apply adhesives or cast electronic components. In addition to the proven, high-performance 2-component PUR seals (FIPFG), we cover other important areas of application for our customers by applying homogeneous 1-component seals. For example, if your application requires higher temperature and/or chemical resistance or may be less compressible than a foamed seal. Our one-component, elastic solutions are also used for electrically conductive seals. We dose silicones, polyurethanes or MS polymers in liquid, unreacted form directly onto your component. True to contour on the smallest geometries, extremely adhesive and durable. Perfect sealing – sealing, gluing, casting directly on the component. Absolutely true to the contour and directly onto your component. We enable our customers to do this in series thanks to state-of-the-art dosing systems.

Request for a quote

ROLLON GMBH

Germany

Compact Rail is a linear system consisting of steel linear rails with induction hardened raceways and high precision radial ball bearing sliders, also made of hardened steel. Thanks to their self-aligning capabilities, Compact Rail linear guides simplify the project, improve the performance and reduce the overall cost of application. Compact Rail linear guides are easy to install on all types of surfaces, including non-machined ones. Compact Rail linear guides feature a robust steel slider with ball bearings, self-centering heads with wipers, longitudinal seals to protect the internal components and a top sealing strip. The slider body is accurately finished with matte longitudinal edge chamfer and a shining ground flat surface. The slider heads are equipped with special slow release felt pads and are free to rotate with respect to the slider body, so that the felts are always in contact with the raceways to ensure optimal lubrication.

Request for a quote

WERNER LANGER GMBH & CO. KG

Germany

For companies from the construction supply industry, we manufacture among others insulating mat holders and plastic dowels in a variety of lenghts. In the sanitary sector, our portfolio/range varies from drainage components through radiator holders in individual parts as well as complete modules to plastic parts for shower cubicles. We also produce components for sealing systems for windows and doors.

Request for a quote

HEBMÜLLER GMBH

Germany

Traditionally, our rubber-to-metal seals are used in the engine and transmission sectors, often with the elastomer FKM / FPM.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

We seal your housings, control cabinets or lighting units, apply adhesives or cast electronic components. In addition to the proven, high-performance 2-component PUR seals (FIPFG), we cover other important areas of application for our customers by applying homogeneous 1-component seals. For example, if your application requires higher temperature and/or chemical resistance or may be less compressible than a foamed seal. Our one-component, elastic solutions are also used for electrically conductive seals. We dose silicones, polyurethanes or MS polymers in liquid, unreacted form directly onto your component. True to contour on the smallest geometries, extremely adhesive and durable. Perfect sealing – sealing, gluing, casting directly on the component. Absolutely true to the contour and directly onto your component. We enable our customers to do this in series thanks to state-of-the-art dosing systems.

Request for a quote

BILLI DICHTUNGSTECHNIK GMBH

Germany

Mechanical seals for the food industry are used in a very broad range of industry sectors, such as in breweries, wine and cider productions, beverage industry, cheese dairies, creameries, juice productions, producers of "soft drinks", etc. In this case, the various components of the seal are made of FDA approved materials. Our mechanical seals are suitable for use in: KSB ®, A.P.V. ®, Alfa Laval ®, FRISTAM ® Lowara ®, TUCHENHAGEN ®, HILGE ®, INOXPA PROLAC ®, INDAG ®, GRUNDFOS ®, JABSCO ®, JOHNSON ®, etc.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Metallic materials of the seal components of GMN labyrinth metal seals - series L/M - guarantee highest resistance against coarse and fine contamination.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

In the FIPFG process, a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. Highly elastic, dimensionally accurate and cost-effective seals that are perfectly connected to the workpiece: KOPP has been offering this to you for more than 15 years in the form of FIPFG sealing systems. In the FIPFG process (formed-in-place-foam-gasket), a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. The possibilities of the technology are as diverse as our customers' requirements for the seals themselves. This makes on-site technical advice essential. Thanks to our experience and technical expertise, we always find the perfect solution with our customers. Through our own toolmaking and construction and application consulting, we can produce quickly, flexibly and cost-effectively.

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

In the FIPFG process, a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. Highly elastic, dimensionally accurate and cost-effective seals that are perfectly connected to the workpiece: KOPP has been offering this to you for more than 15 years in the form of FIPFG sealing systems. In the FIPFG process (formed-in-place-foam-gasket), a 2-component sealing system in a still liquid, non-reacted form is applied “in-situ” directly and true to the contour to the component using a robot. The possibilities of the technology are as diverse as our customers' requirements for the seals themselves. This makes on-site technical advice essential. Thanks to our experience and technical expertise, we always find the perfect solution with our customers. Through our own toolmaking and construction and application consulting, we can produce quickly, flexibly and cost-effectively.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Sealing sets for oil motors Material: NBR Category Hydraulic systems, valves and components / Hydraulic motors / Accessories / Sealing kit Product number supplier 46050019

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Sealing sets for oil motors Material: NBR Category Hydraulic systems, valves and components / Hydraulic motors / Accessories / Sealing kit Product number supplier 46050019

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste MF. Silver-grey high-temperature paste with solid lubricants Description Castrol Molub-Alloy Paste MF (previous product name Castrol Optimol Paste MF) is particularly suitable for assembling screw connections in the high temperature range up to +1100 °C . Even under extreme pressures, it protects the surfaces from scoring, corrosion and seizing. In high-temperature areas, in wet conditions and in aggressive environmental influences, Castrol Molub-Alloy Paste MF seals the components and ensures good separation. Application Castrol Molub-Alloy Paste MF can be used for components at risk of corrosion, exposed to high temperatures and the environment , such as hot-screw connections, spark plug and lambda sensor threads.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FILTERTECHNIK JÄGER GMBH

Germany

Pleated Filter Cartridge Type: PPA Pleated PP-Membrane or nonwoven PP support nonwoven Hard cage Core + end caps made of 100 % polypropylene, meet requirements of FDA guidelines. Thermal welding processes seal all components No adhesives or extractable materials Version: DOE SOE 226 – O-Ring / Bayonet / Spear P7 SOE 222 – O-Ring / Flat P3 SOE 222 – O-Ring / Spear P8

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers finished or semi-finished parts directly formed from polyimide powder with all the attributes of sintered PI. The advantage of direct formed parts are the lower costs as quantitiy is increasing. Due to almost zero percent waste during production it can be a more economic production method. Machined parts are widely used for small series high precision applications. Polyimide direct formed parts can be used in different applications: Automotive industry: racing engine fuel line. Jet engine: vane bushing or lock nut insert. Industrial machinery: hotrunner systems nozzles or plasma cutting torch as gas distributers or sealing components. Semicon HDPCVD Equipment: e.g. heater coil spacer. Life sciences: rotor seal or pneumatic surgical tool vane.

Request for a quote

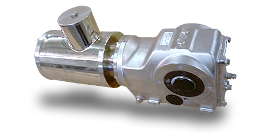

KAISER-MOTOREN GMBH

Germany

Stainless steel motors are used in sanitary areas such as in the food and beverage industry or in the pharmaceutical sector. The smooth surface of the motors is designed in accordance to the EHEDG guidelines to avoid dirt accumulation. To ensure longlasting and lowmaintenance operation, critical components such as bearings and seals are specially tested. Due to an extensive stock of motor components, standard and special motors can be delivered in a short time. Here are some of the common specifications Sizes 63160 0.18 to 22 kW 2 8 pole windings Special windings Enclosure IP66, optional IP69K Special shaft ends Terminal box or cables

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – Large container / handling stations (tubs) are semi-automatic system components for separating, filling, sealing and capping tubs and canisters and can be used individually or in combination. This enables the precise and modular realisation of your specific tasks on the basis of tried and tested stations. Container separating stations Filling positions with filling valve(s) or manual filling stations Sealing stations with head space gassing or evacuation Capping and screwing systems We would be delighted to integrate these or other handling stations in your production process. A common, unified transport system is only one reason for the reliability of each station and the interaction with the upstream and downstream processes. Buffer sections and synchronisation devices are standard here, and can also be combined with our stockpiling systems.

Request for a quote

ALPIN RUBBER AND PLASTIC TECHNOLOGIES

Turkey

Our rubber weatherstrips serve as essential components for sealing gaps between automotive body panels, windows, and doors. Designed to provide effective insulation against weather elements, they play a crucial role in our company's mission to produce high-quality weatherstrips. By preventing air and water leakage, our weatherstrips contribute to reducing wind noise and enhancing energy efficiency

Request for a quote

NEDEX KIMYA SAN VE TIC A.S.

Turkey

NEDEX secondary sealant MELTEX hotmelt butyl (hot melt sealant) is a 100% solids, single-component sealant designed for the sealed insulating glass industry. It is formulated from butyl rubber, synthetic polymers and elastomers to give outstanding adhesion to glass and aluminum when fabricated manually or reactivated in semi- automatic equipment. The product is resistant to degradation from ultraviolet light, temperature extremes and water immersion. MELTEX hotmelt butyl is is compatible with inner sealants of NEDEX such as KU-83B and PIB-996. They can be used together, there will be no chemical reactions. Before using MELTEX together with other inner sealants chemical compatibility tests should be done. MELTEX is a secondary sealant for Insulating Glass Unit with specifications according to EN 1279.

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Trufl ate Automotive interchange style • Parker 10-Series • Rectus 55KM • Tomco A2100/PT400 Materials: • Machined components are manufactured using solid Steel or Brass bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • 1/4” couplers constructed of Brass with Steel sleeve and Steel tubular valve as standard • 3/8” and 1/2” couplers constructed of Steel as standard with Steel tubular valves Seal Components: • Nitrile (Buna-N) seals are standard providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable to MIL-C-51234 • Snap-Tite H/IH and Faster TNV/TNL Materials: • Machined components are manufactured using solid Steel, Brass, or 316 Stainless Steel bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel componentry is plated using ROHS Compliant Trivalent Chrome • Steel coupler sleeves are hardened to resist deformation and maximise service life • Steel nipples are machined from high-strength Steel and induction hardened • Tubular ‘TV’ valves are constructed from Steel bar stock and are designed for optimum performance in pneumatic applications Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F) • All couplers incorporate a PTFE anti-extrusion ring to protect the seal components from dynamic impulse damage • ¼” to 1” valve seals are crimped in place to maintain integrity during excessive flow conditions and

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • European Screw-Together Interchange • Inteva STG-Series, Faster CVV-Series, DNP PVV3, Voswinkel Type-HS Materials: • Machined components are manufactured using solid Steel bar stock. • Steel retaining rings, and springs maximise service life in rugged environments. • Steel componentry is plated using ROHS Compliant Trivalent Chrome. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -25°C to +125°C (-13°F to +257°F). • Nipples have a PTFE Anti-Extrusion ring to prevent O-Ring damage during dynamic impulse service.

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • High Pressure Screw-Together Interchange • Parker/Pioneer 3000-Series, Enerpac C604, Stucchi IVHP • Hansen WS56000, Snap-Tite 76-Series, DNP PVM Materials: • Machined components are manufactured using solid Steel or 316 Stainless Steel bar stock • Chrome Steel ball valve is mechanically seated to improve low pressure sealing performance • Steel nipples are machined from solid high strength Steel bar stock • Steel componentry is plated using ROHS Compliant Trivalent Chrome Seal Components: • Urethane seal is standard in ball valve couplers and provides resistance to extrusion when subjected to high pressure - temperature range -40°C to +82°C (-40°F to +180°F) • Nitrile seals are standard in poppet valve couplings, providing a temperature range of -40°C to +121°C (-40°F to +250°F)

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable to ISO15171-1 • Parker PD-Series, Aeroquip FD90, Tomco Series DK Materials: • Machined components are manufactured using solid Steel bar stock • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life • Steel nipples are machined from solid Steel bar stock and hardened • Steel componentry is plated using ROHS Compliant Trivalent Chrome Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F) • PTFE anti-extrusion ring protects main coupler O-Ring from dynamic impulse pressure damage

Request for a quote

DIXON GROUP EUROPE LTD

United Kingdom

Interchange Data: • Interchangeable with Snap-Tite 71-Series Materials: • Machined components are manufactured using solid Steel or 316 stainless bar stock. • Stainless Steel balls, retaining rings, and springs maximise corrosion resistance and extend service life. • Steel componentry is plated using ROHS Compliant Trivalent Chrome. • Steel coupler sleeves are hardened to resist deformation and maximise service life. • Steel nipples are hardened to provide heavy duty performance. Seal Components: • Nitrile (Buna-N) seals are standard, providing a temperature range of -40°C to +121°C (-40°F to +250°F). • All couplers and nipples incorporate PTFE or TPC-ET anti-extrusion rings to protect the seal components from dynamic impulse damage.

Request for a quoteResults for

Component seals - Import exportNumber of results

56 ProductsCountries

Category

- Fittings, pipe, tube and hose - plastic (12)

- Lubricants, industrial (6)

- Foams, rubber (4)

- Seals (4)

- Precision measuring instruments (2)

- Cable ducts (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Diesel engines (1)

- Double glazing (1)

- Electric motors - dC (1)

- Extrusion of rubber and plastic (1)

- Filtering equipment and supplies (1)

- Gas detectors (1)

- Glass, insulating (1)

- Hydraulic equipment (1)

- Insulating seals (1)

- Internal transport systems (1)

- Lubricants for cars (1)

- Mechanical engineering - custom work (1)

- PVC, polyvinyl chloride (1)