- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chain conveyors

Results for

Chain conveyors - Import export

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

the context of the ELITE conveyor chain range, iwis suppliesa wide variety of chains according to standards DIN 8165 and DIN 8167, as well as models manufactured according to British Standard with dimensions in inches, and highly diverse special versions. Bush conveyor chains are often used for conveying tasks involving long transport distances at relatively low speeds. Since only a small minority of chains used in the industry are totally compliant with one specific standard, ELITE conveyor chains are custom-made to a specific customer order and consequently fulfil a large number of special requirements. Product range: • Bush conveyor chains according to DIN 8167 – M Series • Carrier chains with rollers according to DIN 8167 – MT Series • Hollow pin chains according to DIN 8168 – MC Series • Hollow pin chains according to DIN 8165 – FVC Series • Scraper chains according to DIN 8165/DIN 8167 • Conveyor chains for the paper industry • Rotary chains

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Highlights: • Wide range of products • Dimensions according to ISO 1275 • Versions with small rollers and transport rollers available • All ELITE chain plates 1 are manufactured using processes such as fine blanking and ball-drifting, so a particularly high Product range: • Double pitch roller chains ISO 1275 • Double pitch roller chains with straight plates ISO 1275 • Double pitch hollow pin bushed chains • Double pitch hollow pin roller chains contact ratio is guaranteed. • Solid, case hardened rollers 2 with good wear resistance • ELITE pins 3 are smooth and have an extra hard surface for increased wear resistance

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH lift tables are efficient transfer units for mergers, crossings or branches in flows of materials. Roller or chain conveyors can be integrated as required. The interlocking lift mechanism combined with a rigid frame protects the unit loads and ensures optimum availability. As an option, variable intermediate lift positions can be included to ensure greater flexibility. The compact dimensions and safety guards expand the range of applications. Turntable with Roller or Chain Conveyor Turntables can divide or merge flows of materials without changing the orientation of the unit loads. The highly dynamic turntable drives from DAMBACH are interlocking units and ensure precise rotational angles of up to 270° with any number of intermediate stops. For optimum occupational safety, our turntables can be fully enclosed. In addition, the innovative modular design guarantees numerous and diverse applications and ease of servicing at the same time.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

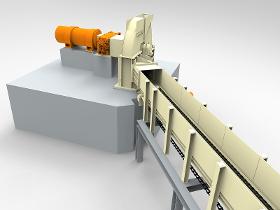

Like belt conveyors, also a chain conveyor is engineered with the purpose of transporting materials. Transporting materials on this type of conveyor commonly proceeds in a horizontal way, but also vertically over a short distance to a higher level is possible.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quote

FÖRDERTEC GMBH

Germany

The conveyor chain is the decisive factor for the functionality of each bulk goods conveyor system. The conveyor system can only be operated efficiently, if this conveyor chain withstands the high loads. Therefore, FörderTec uses a welding and production method for conveyor chains that is far superior to normal chains with respect to quality and durability. These forked lug chains are suitable for any application, even under the toughest of conditions. All forked lug chains are produced in our factory. We can react quickly and flexibly to each of your specific requirements. We are prepared for any eventuality – broken chain, emergency failure, system standstill. High-quality materials and special finishing methods make our conveyor chains extremely stable and fail-safe:

Request for a quote

PRESSTA EISELE GMBH

Germany

Chain conveyor for heavy profiles Available for following automatic cutting machines: Profilma 510 E, 600 R Max. load 5.300 KG Dimension of stories fix, e.g. max. cutting range of the saw Conveying length 1.550 mm Profile length from 500 – 7.000 mm Pneumatic gripper for good feeding of the profiles Buffer storage in front of the loader Infeed of material by driven belts

Request for a quote

MINEBEA INTEC GMBH

Germany

Vistus metal detectors are capable of detecting both ferrous and non-ferrous metals and are specifically designed for the food industry. They can be supplied mounted on a belt or chain conveyor, allowing an easy and fast integration into your processing or packaging line. Sturdy and torsion free construction made of 1.4301/AISI304 stainless steel High quality drives: maintenance free three-phase motor with worm gear or three phase drum motor Maximum detection performance through optimum vibration control and metal free zone Available standard coil sizes: 75 x 30 mm up to 275 x 60 mm Extremely compact: control unit fully integrated in detection coil Standard IP65 protection class, IP69K optionally available for enabling high pressure water cleaning

Request for a quote

GURTEC GMBH

Germany

Used for heavy unit goods conveyors Chain-driven and non-chain-driven Dimensions: Roller diameter 20 – 102 mm (3/4” to 4”) Shaft diameter up to 20 mm as standard (3/4”) Roller length up to 1,500 mm (60 ”)

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length. Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell. External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible. Step feeder, Conveyor feeder, Chain feeder, Swivel arm feeder, Loading tables, Bowl feeder, Alignment station

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Highly adhesive lubrication of moving parts, e.g. valve spindles, piston rods, wire cables, drag cables, drive and conveyor chains, hinges and guides, at highly corrosive conditions in food processing technology Temporary corrosion protection of ferrous and non-ferrous metals, in particular in highly corrosive atmospheres, such as industrial atmospheres, outdoor weathering under roofs of semi-finished products and finished products Shipping protection of packed and unpacked machines and machine parts, apparatuses and equipment goods under extreme climatic conditions Advantages and benefits Highly adhesive oil with very good creep and lubrication properties Optimal corrosion protection through high effectiveness of the corrosion protection additive After the solvent has dried, forms a transparent, highly adhesive oil film Contains non-ferrous metal deactivator NSF H1-registered

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Highly adhesive lubrication of moving parts, e.g. valve spindles, piston rods, wire cables, drag cables, drive and conveyor chains, hinges and guides, at highly corrosive conditions in food processing technology Temporary corrosion protection of ferrous and non-ferrous metals, in particular in highly corrosive atmospheres, such as industrial atmospheres, outdoor weathering under roofs of semi-finished products and finished products Shipping protection of packed and unpacked machines and machine parts, apparatuses and equipment goods under extreme climatic conditions Advantages and benefits Highly adhesive oil with very good creep and lubrication properties Optimal corrosion protection through high effectiveness of the corrosion protection additive After the solvent has dried, forms a transparent, highly adhesive oil film Contains non-ferrous metal deactivator NSF H1-registered Also available as spray version OKS 3601

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Our fully automatic flowpack machines are suitable either for high-speed applications or airtight packaging requirements, depending on the version selected. The machines feature either rotating or box motion transversal sealing units, with selection of a longitudinal seam either above or below. Each machine can be combined with a wide range of feed systems, such as finger conveyor chains or infeed belts. With our ability to handle everything from PP or aluminium laminated films through to Tyvek® – anything is possible. PE-coated paper can also be used for flowpack production. Our flowpack machines are also available as hygienically designed versions.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Paper or film? Stay flexible! A single machine can now deliver both film and paper packaging applications. The continuous Form Fill and Seal Machines paper X hybrid are designed for packaging goods in paper or film. A simple changeover ensures you are ready for the new product and the new packaging material. Whether using a chain infeed or infeed conveyor, the machines stand apart through their continuous packaging process – without stop-and-go – maximising efficiencies by ensuring there is no downtime when sealing or glueing. Our paper packaging solutions are available in different versions, depending on how flexible you need to be: - the basic model paper X features paper packaging with overlap on top - the paper X hybrid features paper and film packaging with overlap on top - the paper X hybrid advance features paper and film packaging with overlap on top and side seal

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The continuous Form Fill and Seal machines of the servo X series are available in five performance ranges and numerous variants. They cover the broadest possible range of horizontal film packaging applications for various industries – and all this with maximum modularity. The machines can be configured individually and thus meet all requirements for the desired performance or type of packaging. Depending on the machine variant, several packaging styles can be flexibly produced with one machine. Whether chain infeed or infeed conveyor, servo X machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Driving and conveyor chains of all designs in open or semi-enclosed operation without a re-lubrication device Roller chains such as motorcycle and bicycle chains Stacker truck chains as well as single or multiple flat-link articulated chains without a re-lubrication device Rope drives and wire pulls; for example, standing, hoisting, traction or winch ropes in hoisting gears, elevators, lifts or mountain railways Flexible drives, bowden and spring cables Moving machine parts exposed to outdoor weathering, such as toothed gearing, guides, closing mechanisms, hinges or sliding surfaces Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Highly adhesive and resistant to throwing off Contains Moₓ-Active for increased performance Excellent wear protection Very good resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 451

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of highly stressed and relatively slowly running gears where due to leakage a grease must be used instead of oil For drives under high and shock load Chain lubrication of e.g. hollow pins, chains in the conveyor and transport field, under the influence of water and vapour and at higher operation temperatures Bearing lubrication of roller and plain bearings at annealing furnaces and drying equipments, manipulators and robots, conveyor and cooling systems, machines of preserve industry, steam sterilizers, etc. Advantages and benefits Best use in corrosive operation conditions with high operation temperatures and high pressure and shock load Economically due to optimum formulation Reduces wear and thereby downtime and enables long-term lubrication Ropy, strongly adhesive, temperature and water resistant, noise dampening, high-load and shock absorbing

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The servo X 800 are the most flexible and powerful of film packaging machines in the horizontal large-format segment – and all this with maximum modularity. They can be configured individually and thus meet all requirements. Whether chain infeed or infeed conveyor, servo X 800 machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

Request for a quote

CRAEMER GMBH

Germany

Original Palgrip® pallets from Craemer offer unparalleled smoothness and tracking on roller conveyors or chain conveyors. The abrasion-resistant anti-slip plates provide excellent slip resistance on the deck or under the runners. The high quality Palgrip® grain structure ensures an absolutely secure hold even in damp conditions. Palgrip® provides an all-round reliable solution to your logistical requirements. Only available from Craemer. The Palgrip® anti-slip coating is resistant to cold and heat, from -30°C to +40°C. Compared to common plastic surfaces, Craemer Palgrip® anti-slip sheets offer absolute slip resistance even in high humidity thanks to their grain structure. The unique Palgrip® anti-slip panels are made from high quality HDPE and are permanently part of the deck and the anti-slip runners will last the lifetime of the pallet. Even in an inclined position, your load remains static on the pallet deck

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer spiral conveyor has stood the test of time for transporting differently-sized and -shaped products vertically. The open construction prevents dirt deposits. Common drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears. The mat chain is equipped with rubberised elements so that large gradient angles can be overcome. Technical data: —Conveyor body material: stainless steel —Difference in height when transporting upward: up to 5 m —Difference in height when transporting upward: up to 7 m —Chain widths: 190.5 mm, 304.8 mm, 381.0 mm, 457.2 mm —3 configurations: 0°, 90°, 180° —Conveying speed: up to 50 m/min —Product weight: up to 25 kg —Optionally with lane divider Optional equipment: —Product guides, design depending on product —Supports to stabilise the conveyor systems at the desired conveying height —other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer stainless steel hygiene system has stood the test of time for transporting general cargo and bulk goods across long distances. The open construction prevents dirt deposits and is suitable for conveying food without packaging. Common mat chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Technical data: —Conveyor body material: stainless steel —Chain width: up to 1400 mm —Conveying speed: up to 80 m/min Optional equipment: —Centre drive+ automatic tensioning station —Retracting end —Hinged nose —Chain washing station —Moving deflecting pulleys —Product guides, fixed or adjustable, design depending on product —Supports to stabilise the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aluminium system has stood the test of time for transporting general cargo and bulk goods across long distances. The design allows for non-cutting and fast installation. Common mat chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Supports, railing brackets, sensors, etc. can be positioned and affixed to the profile as desired with slot nuts. Technical data: —Conveyor body material: Aluminium/stainless steel —Chain width: up to 1400 mm —Conveying speed: up to 80 m/min Optional equipment: —Centre drive + automatic tensioning —Retracting end —Hinged nose —Moving deflecting pulleys —Product guides, fixed or adjustable, design depending on product —Supports to stabilise the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer continuously operating spiral system cools, ferments or freezes general cargo and bulk goods. The products are transported on a plastic mat conveyor chain. The chain is wound around one or two rotating towers in a spiral. The design of the machine permits the handling of unpackaged food. The products' discharge temperature can be changed by adjusting the throughput time and/or the temperature in the module. In addition to heat or cooling treatment, differences in height up to 5 m can be overcome at the same time. Technical data: —Chain width: up to 1,400 mm —Usable chain length: up to 1,000 m —Temperature range: +1°C to +85°C —Insulating hood with access doors and inspection windows according to customer request —Cooling unit with direct evaporation or flow-through cooler with coolant (e.g., Sole) —Heat exchanger with hot water or steam connection

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer FIFO spiral buffer stores general cargo and bulk goods. The products are transported on a plastic mat conveyor chain. The chain is wound around one or two rotating towers in a spiral. The design of the machine permits storing unpackaged food. The machine works according to the First In-First Out principle. Technical data: —Chain width: up to 1,400 mm —Usable chain length: up to 1,000 m —Independent electrical control system Optional equipment —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer mat table cools, ferments or freezes general cargo and bulk goods. The products are transported on a plastic mat conveyor chain. The design of the machine permits treating unpackaged food. The products' discharge temperature can be changed by adjusting the throughput time and/or the temperature in the module. The mat table is a cost-effective and space-saving solution for short throughput times. Technical data: —Chain width: up to 1,500 mm —Usable chain length: up to 10 m —Temperature range: +1°C to +85°C —Insulating hood with access doors and inspection windows according to customer request —Cooling unit with direct evaporation or flow-through cooler with coolant (e.g., Sole) —Heat exchanger with hot water or steam connection

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The line for tree-length logs is designed for the processing of whole logs with lengths of up to20 meters: With the log feed, debarker, washingsystem, dosing system all the way to the highlyecient disc chippers, the production of highquality chips is guaranteed Key featuresFeeding of the wood from the truck or storage areaLarge gantry or rotating cranes for loads of up to 30 metric tons of woodExtremely robust longitudinal chain conveyors or chip chutesLarge conveying cross-sections and laterally arranged chutesDrum debarkersChipper feeding onveyors for large throughputs Metal sensor and roller conveyor cleaning systemDisc chipperAdvantagesGentle de-barkingMinimal ne material content among chipsHigh safety against jamming of logs

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The plantation wood line is designed for processing uniform wooden logs grown in plantations. These logs have lengths between 3 and 8 meters and diameters between 100 and 450 mm: With the log feed, dosing step conveyor, debarker, washing system, dosing system all the way to the highly-ecient disc and drum chippers as well as the mills for the preparation of bark, the production of highquality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Dosing step conveyor for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Depending on the debarking demand, use of drum or rotor debarker Disk or drum chipper Advantages Robust, highly controllable wood feed Debarker adapted to the debarking demand Minimal ne material content High lling level and high utilization of chipper capacity High operational safety

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The long-wood line is designed for processing logs with lengths between 3 and 8 meters and diameters between 50 and 850 mm: With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient disc chippers, the production of high-quality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Buer capacity of up to 30 minutes/ 80 metric tons bone dry material Step feeder for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Rotor debarker for eective debarking even at extremely low winter temperatures Robust drum chipper Advantages Highly controllable wood feed Ecient debarking Perfect chip quality thanks to the adjustability of to the feed material mixture Minimal ne material content High lling level and high utilization of chipper c High operational safety

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

iwis offers a wide range of roller chain products that fulfil the requirements of a variety of conveyor applications. We can supply virtually any special chain version – even the most difficult and complex design – for use in highly diverse application areas: corrosion-free, lube-free, maintenance-free and more.

Request for a quoteResults for

Chain conveyors - Import exportNumber of results

62 ProductsCountries

Company type

Category

- Mechanical transmission systems and components (11)

- Conveyor belts (6)

- Silicones (5)

- Sealing and wrapping - machinery and equipment (4)

- Chains (3)

- Goods handling systems, continuous (3)

- Storage equipment and systems (3)

- Wood veneer - machinery and equipment (3)

- Conveyor systems (2)

- Palletising machinery (2)

- Monitoring and control equipment (1)

- Bearings - ball, needle and roller (1)

- Chains with articulated links (1)

- Gas and oil - exploitation (1)

- Metal detectors (1)

- Pallets (1)

- Pipes and tubes - ferrous metal (1)

- Transportation chains (1)