- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chain conveyors

Results for

Chain conveyors - Import export

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

Like belt conveyors, also a chain conveyor is engineered with the purpose of transporting materials. Transporting materials on this type of conveyor commonly proceeds in a horizontal way, but also vertically over a short distance to a higher level is possible.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We offer a great variety of loading systems for all the machines, dependent on the material, tube diameter and tube length. Tubes that have already been formed and with added components can also be loaded without any issues. The appropriate orientation is therefore very important, when loading the tube into the production cell. External workpieces, such as nuts, flanges, supporting sleeves can be added to the system in a controlled manner and included in any subsequent processing steps. A great variety of loading volumes is possible. Step feeder, Conveyor feeder, Chain feeder, Swivel arm feeder, Loading tables, Bowl feeder, Alignment station

Request for a quote

CRAEMER GMBH

Germany

Original Palgrip® pallets from Craemer offer unparalleled smoothness and tracking on roller conveyors or chain conveyors. The abrasion-resistant anti-slip plates provide excellent slip resistance on the deck or under the runners. The high quality Palgrip® grain structure ensures an absolutely secure hold even in damp conditions. Palgrip® provides an all-round reliable solution to your logistical requirements. Only available from Craemer. The Palgrip® anti-slip coating is resistant to cold and heat, from -30°C to +40°C. Compared to common plastic surfaces, Craemer Palgrip® anti-slip sheets offer absolute slip resistance even in high humidity thanks to their grain structure. The unique Palgrip® anti-slip panels are made from high quality HDPE and are permanently part of the deck and the anti-slip runners will last the lifetime of the pallet. Even in an inclined position, your load remains static on the pallet deck

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

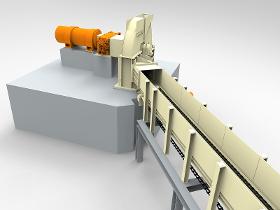

The line for tree-length logs is designed for the processing of whole logs with lengths of up to20 meters: With the log feed, debarker, washingsystem, dosing system all the way to the highlyecient disc chippers, the production of highquality chips is guaranteed Key featuresFeeding of the wood from the truck or storage areaLarge gantry or rotating cranes for loads of up to 30 metric tons of woodExtremely robust longitudinal chain conveyors or chip chutesLarge conveying cross-sections and laterally arranged chutesDrum debarkersChipper feeding onveyors for large throughputs Metal sensor and roller conveyor cleaning systemDisc chipperAdvantagesGentle de-barkingMinimal ne material content among chipsHigh safety against jamming of logs

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The long-wood line is designed for processing logs with lengths between 3 and 8 meters and diameters between 50 and 850 mm: With the log feed, step feeder, debarker, washing system, dosing system all the way to the highly-ecient disc chippers, the production of high-quality chips is guaranteed. Key features Feeding of wood by means of handling cranes or loading vehicles Robust chain cross conveyors for the direct feed of logs Buer capacity of up to 30 minutes/ 80 metric tons bone dry material Step feeder for absolutely consistent volumes Metal sensor and roller conveyor cleaning system Rotor debarker for eective debarking even at extremely low winter temperatures Robust drum chipper Advantages Highly controllable wood feed Ecient debarking Perfect chip quality thanks to the adjustability of to the feed material mixture Minimal ne material content High lling level and high utilization of chipper c High operational safety

Request for a quote

OGE GROUP

Germany

SCRAPER CHAIN CONVEYOR AND APRON

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The chain-on-edge and spindle chain conveyor is used for the continuous or cyclic transport of workpieces. It's typical feature is its rotating spindles. The rotational movement of these spindles can be infinitely set. Typically, the rotational movement starts during the painting process; if desired, it can also be installed in the evaporation and drying zone. VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

At the time of workpiece transfer, a change is made from longitudinal transport to crosswise transport. In contrast to curve conveyors, angular transfer systems operate in cycles. Depending on the requirement, they can be planned as collecting or separating device. Possible configurations include 90° or 180° belt, chain or rake cross conveyors. A rake or crank rocker linkage or an electro-pneumatic control can be used to transfer workpieces from lenthwise to crosswise or vice versa. The VEN BRUSH system equipment Solutions possible with the VEN MOVE series cover several functions such as rotating, turning, transferring, stacking, feeding, accumulation, separation or allocation.

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

We offer you exactly the right conveyor and drive chains to match your transport rollers. Each chain is tailor-made in material and design. This means that you benefit from low maintenance costs and ensure the long-term stability and safety of your goods transport system. The chains are available as yard goods or as ready-to-install, deflected and closed chains. At TRAPOROL you’ll get exactly the right chain and driven wheels to fit your transport rollers on request. We’ll ensure that the material and design of every chain is exactly tailored to your purpose. So you’ll make a big reduction in maintenance costs and gain high performance for your transport system long term. Whether by the metre or ready-to-assemble and enclosed: all the chain wheels supplied are produced in accordance with DIN ISO 606 (ex-DIN ISO 8187) and meet even the highest demands.

Request for a quoteResults for

Chain conveyors - Import exportNumber of results

11 ProductsCompany type