- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire forming

Results for

Wire forming - Import export

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Wire forms can have a shape that is limited almost only by fantasy. Many of them have some kind of spring functionality, for example some quick fastening applications. In most products, the material is stressed in bending and they can be looked upon as leaf springs made from wire. Wire forms are manufactur

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Consistent customer focus, a high degree willingness to innovate, continuous investment and qualified employees are the basis for WDI's leading position in cold forming wire. Our products have applications in all industrial manufacturing sectors, particularly in the automotive industry, mechanical engineering, the construction industry and the electrical industry. The leading manufacturers in the respective industries number amongst our customers. We supply the European and international market with cold-forming wires in sizes ranging from 1.5 mm to 42 mm.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

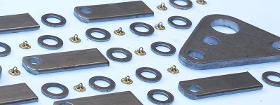

As a competent industrial partner, we produce stamped, bent-wire and formed components from stainless steel, non-ferrous metals and regular steel in a consistent quality. Dependability and flexibility characterize our performance. Our experience and technical know-how enable fast response and economical pricing. Benefit from the experience our staff have gathered with these products. We can competently process small as well as large orders. Possible material thicknesses: 0.5 to 4.5 mm. Possible materials: Regular steel, stainless steel, brass, copper, light metals. Available with all standard surfaces.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Our Speedmax is the fastest available wire and tube forming automation solution available on the market for bending machines. By combining NC finger benders with our servo-electric transfer, the Speedmax with its 90 servo axes can reach a speed of up to 4,000 machining steps per minute. The SPEEDMAX is available in three variants (S,M,L). The SPEEDMAX (S) has 20 processing stations and can produce up to 200 parts per minute. The machine concept combines the advantages of 3D-NC wire bending and wire bending by slides. Bending, embossing, notching, flattening, joining, punching, swaging of tubes and wire are possible production technologies in the 20 processing stations. The new SPEEDMAX L has actually 20 processing stations and can produce up to 60 parts per minute. The SPEEDMAX L can work with tube and wire up to a diameter of 12mm and a feed length of 50cm. Various bends in all levels and in the current equipment up to four swaging processes are possible.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For gripping small parts and forming wires • Smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles with ergonomically shaped ESD multi-component sleeves, electrically conductive • Made of tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For gripping small parts and forming wires • Smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles coated with plastic • Made of tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• Most popular shape for assembly work, trimming printed circuit boards, also for radio and telephone work • For gripping small parts and forming wires • Tips bent 45°, smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles with ergonomically shaped ESD multi-component sleeves, electrically conductive • Made of tool steel, forged, oil-hardened

Request for a quoteResults for

Wire forming - Import exportNumber of results

9 ProductsCompany type