- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wire forming

Results for

Wire forming - Import export

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

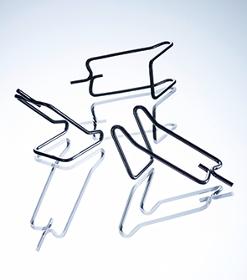

Wire forms can have a shape that is limited almost only by fantasy. Many of them have some kind of spring functionality, for example some quick fastening applications. In most products, the material is stressed in bending and they can be looked upon as leaf springs made from wire. Wire forms are manufactur

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Consistent customer focus, a high degree willingness to innovate, continuous investment and qualified employees are the basis for WDI's leading position in cold forming wire. Our products have applications in all industrial manufacturing sectors, particularly in the automotive industry, mechanical engineering, the construction industry and the electrical industry. The leading manufacturers in the respective industries number amongst our customers. We supply the European and international market with cold-forming wires in sizes ranging from 1.5 mm to 42 mm.

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

We produce the necessary forming machines for materials such as wire, pipe, rod, bar, plate, coil sheet, which are shaped in the industry.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg outsourcing steel wire forms by carbon steel wire, stainless steel wire, spring steel wire, we can custom fabricate almost any wire form using our automated wire bending robots. Beyond getting the shape you need, you can also order custom wire forms in a various of materials, such as stainless or galvanized steel, with a variety of coating options, including soft polymers and scratch-resistant hard polymers. We custom producing all kinds of steel wire forms, includes steel wire brackets,steel wire hooks, steel wire baskets, spring bracket, steel wire cover, steel wire lampshade for lighting, steel wire clip, spring steel wire formed shield, wire forms, steel wire hooks, steel wire suspend slings, and all steel wire parts. Our steel wire forming products mainly use in Animal stock breeding, Garden & constructions, Automobile,Machinery…

Request for a quote

ANAMAS SPRING MANUFACTURING AND MACHINE TRADING LTD

Turkey

Manufactured for specific purposes according to the customer's need for use, used for holding, fixing and locking, different sizes, types and sizes are produced according to the customer's desire. Areas of use: auto parts, agricultural machinery, sewing machines, medical devices, military defense industries, and household devices.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). At PRUFREX, single-chamber and multi-chamber coils can also be achieved using two-wire windings. For specific magnetic flux requirements, we apply wires of different thicknesses to the coil form. Two different wire thicknesses, from 0.045 to 0.71 millimetres, on coil forms with press-in ferrite or metallic cores.

Request for a quote

CETEC SYSTEMS SONDERMASCHINEN- VERTRIEBS GMBH

Austria

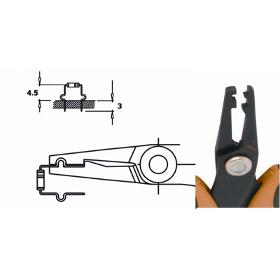

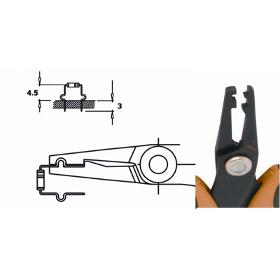

Forms the component wire in C-shape and cuts the residual part at 4mm. ESD. Steel thickness 3mm, Length 150mm

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

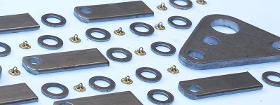

As a competent industrial partner, we produce stamped, bent-wire and formed components from stainless steel, non-ferrous metals and regular steel in a consistent quality. Dependability and flexibility characterize our performance. Our experience and technical know-how enable fast response and economical pricing. Benefit from the experience our staff have gathered with these products. We can competently process small as well as large orders. Possible material thicknesses: 0.5 to 4.5 mm. Possible materials: Regular steel, stainless steel, brass, copper, light metals. Available with all standard surfaces.

Request for a quote

CETEC SYSTEMS SONDERMASCHINEN- VERTRIEBS GMBH

Austria

Forms the component wire in C-shape and cuts the residual part at 4mm. ESD. Steel thickness 3mm, Length 150mm

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Our Speedmax is the fastest available wire and tube forming automation solution available on the market for bending machines. By combining NC finger benders with our servo-electric transfer, the Speedmax with its 90 servo axes can reach a speed of up to 4,000 machining steps per minute. The SPEEDMAX is available in three variants (S,M,L). The SPEEDMAX (S) has 20 processing stations and can produce up to 200 parts per minute. The machine concept combines the advantages of 3D-NC wire bending and wire bending by slides. Bending, embossing, notching, flattening, joining, punching, swaging of tubes and wire are possible production technologies in the 20 processing stations. The new SPEEDMAX L has actually 20 processing stations and can produce up to 60 parts per minute. The SPEEDMAX L can work with tube and wire up to a diameter of 12mm and a feed length of 50cm. Various bends in all levels and in the current equipment up to four swaging processes are possible.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical data The AM 03 is an electropneumatic, modular stripper-crimper for rapid and reliable processing of loose male and female contacts. The contacts are automatically fed by a feeding bowl. The adjustments of the stripping and crimping depth is motoric. 50 different programs can be stored. Adjustments and programming is done with the touch display. The touch display shows all important data, functions and status. The machines may be adapted to different contacts and wires using the corresponding tools. Options Adapter for special blades V-radius blades Z+F crimp force monitor Other crimp forms: B-Crimp, hex Special wire centralizer Form blades

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

PROYA METAL MUH. PROJE. INS. LTD. STI

Turkey

Gas Metal Arc Welding (GMAW), commonly known as MIG welding, is a welding process where an electric arc forms between a consumable electrode and the workpiece, generating the necessary heat for welding. The electrode, continuously fed as a solid wire, melts and forms the weld metal as it is consumed. The welding area is protected from atmospheric contamination by shielding gases or gas mixtures from the welding torch, ensuring high-quality welds by preventing defects caused by even minimal air exposure.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg has a friend factory working on wire forming production of all kinds of spring manufacturers, pressure spring, tension spring, torsion spring, clamp spring, shrapnel, special-shaped spring, stainless steel spring, metal spring, tower spring.... There are square steel, flat steel, various stainless steel and tin bronze spring and so on. The wire formed parts as belows: Large spring bending Shaped spring Compression spring Linear spring Hardware hook Torsion spring series Tensile spring Buckle retaining ring Clockwork coil roll Custom Springs Production equipment: computer spring forming machine, automatic spring coiling machine of various specifications, advanced double end spring grinding machine and torsion spring machine of various specifications, etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For gripping small parts and forming wires • Tips bent 45°, smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles coated with plastic • Made of tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For gripping small parts and forming wires • Smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles with ergonomically shaped ESD multi-component sleeves, electrically conductive • Made of tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For gripping small parts and forming wires • Smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles coated with plastic • Made of tool steel, forged, oil-hardened

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• Most popular shape for assembly work, trimming printed circuit boards, also for radio and telephone work • For gripping small parts and forming wires • Tips bent 45°, smooth inside jaws, edges rounded • Tight-fit joint movement • With box-joint and opening spring • Handles with ergonomically shaped ESD multi-component sleeves, electrically conductive • Made of tool steel, forged, oil-hardened

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

For decades, our precision staple and anchor wire products have been used in high-quality toothbrushes and fine brushes. We are experts in custom-engineering precision toothbrush staple wire to your exacting shape, profile, and material requirements. Using sophisticated wire forming technology, our custom-made anchor and staples wires are renowned worldwide for their increased tuft retention and high pull-out resistance in toothbrush bristles. Advantages As a leader in toothbrush anchor wire technology, we consistently work to tight wire tolerances in the fabrication of simple and complex wire shapes for superior dimensional control. Precision wire geometries that significantly improve tuft retention Tightly controlled alloy purity, consistency and composition for improved performance Improved die wear, formability and platability Stringent quality control to ISO 9001 Short lead times and small batch sizes

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our weld wire sheathing material is used in both flux cored wire and metal cored welding wire processes. The wire sheathing is formed into a tubular product by our customers and the center of the tube contains the ‘fill’ (flux, metal powders, etc) to bring the wire to the desired chemistry. The finished wire is used across a wide breadth of industries in processes such as: Submerged Arc Welding (SMAW) Gas Metal Arc Welding (GMAW) Wire Arc Thermal Spray Flux cored welding wire producers use our metal sheathing materials to prepare finished wire for thermal spray and in surfacing applications, in high temperature and corrosive environments. Cobalt Our Ductile Cobalt Alloys are used to produce wire to hardface applications in the construction, mining, and oil and gas industry. Our proprietary process allows us to offer high Cobalt containing products (91% Cobalt or more) while maintaining a highly ductile strip for wire forming.

Request for a quote

TECNO IMPIANTI SRL

Italy

Tecno Impianti designs and manufacture a series of horizontal wire drawing bullblocks Mod. MO/P, for the drawing of cold heading wire. These wire drawing bullblocks are utilized for big productions of drawn wire and are meant for wire drawing companies which produce cold heading wire or for big manufacturers of fasteners who execute the wire drawing off-line and take the drawn wire to the cold heading machines, in the form of wire coiled on wire carriers or as bound coils. The horizontal wire drawing bullblocks Mod. MO/P are manufactured by us in 4 different models, for covering a range of wire diameters between 6,0 and 30,0 mm. The drawn wire is taken-up on a rotating platform positioned into a hole in front of the capstan. It is taken-out with wire carriers or through a coil extractor.

Request for a quote

TECNO IMPIANTI SRL

Italy

Tecno Impianti designs and manufacture a series of horizontal wire drawing bullblocks Mod. MO/P, for the drawing of cold heading wire. These wire drawing bullblocks are utilized for big productions of drawn wire and are meant for wire drawing companies which produce cold heading wire or for big manufacturers of fasteners who execute the wire drawing off-line and take the drawn wire to the cold heading machines, in the form of wire coiled on wire carriers or as bound coils. The horizontal wire drawing bullblocks Mod. MO/P are manufactured by us in 4 different models, for covering a range of wire diameters between 6,0 and 30,0 mm. The drawn wire is taken-up on a rotating platform positioned into a hole in front of the capstan. It is taken-out with wire carriers or through a coil extractor.

Request for a quote

BALABAN54 MAKINA DIS TIC LTD STI

United Kingdom

Enables remoulding of the butter for extraction of water content By means of the moulds, the butter can be provided in circular, rectangular or square form. Adjustable cutting wires; enables partitioning of the butter in desired weight volumes. Capacity: Varies according to assigned personnel. Average 500 KG

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

Thermal spraying processes (as classified in the EN 657 and ISO 14917 standards) offer a wide range of applications within modern surface technologies. Components made from a wide range of base materials can be coated with layers of high-melting-point metals or ceramics to protect them against wear and corrosion. Furthermore, thermally conductive or heat-insulating layers can be applied to highly thermally stressed components. Almost all coating materials that can be produced in powder or wire form can be processed in this way. During thermal spraying, the coating materials are fed into — and melted by — an energetic heat source (fuel gas oxygen flames from combustible gas, arcs or plasmas of noble gases such as argon, hydrogen, nitrogen, helium). The particles, which are either softened or fully molten, are accelerated in the direction of the workpiece and collide with it at high speed (40–600 m/s).

Request for a quote

BKM PRÄZISIONSWERKZEUGE STANZ UND BIEGETEILE GMBH

Germany

Results for

Wire forming - Import exportNumber of results

35 ProductsCountries

Company type

Category

- Building hand tools, non-power (4)

- Laser - cutting and welding machines (3)

- Aluminium wires and cables (2)

- Bending - steels and metals (2)

- Hot forming (2)

- Wire drawing and wire rod working machines (2)

- 3D scanner (1)

- Chains, wire - with non-welded links (1)

- Coil winders (1)

- Custom design springs (1)

- Dairies - machinery and equipment (1)

- Electrical & Electronic Components (1)

- Forming - steels and metals (1)

- Galvanization - steels and metals (1)

- Import-export - steels and metals (1)

- Metal industrial presses (1)

- Milling - steels and metals (1)

- SMALL METAL PARTS (1)

- Steels and metals - machining (1)

- Stud farms (1)